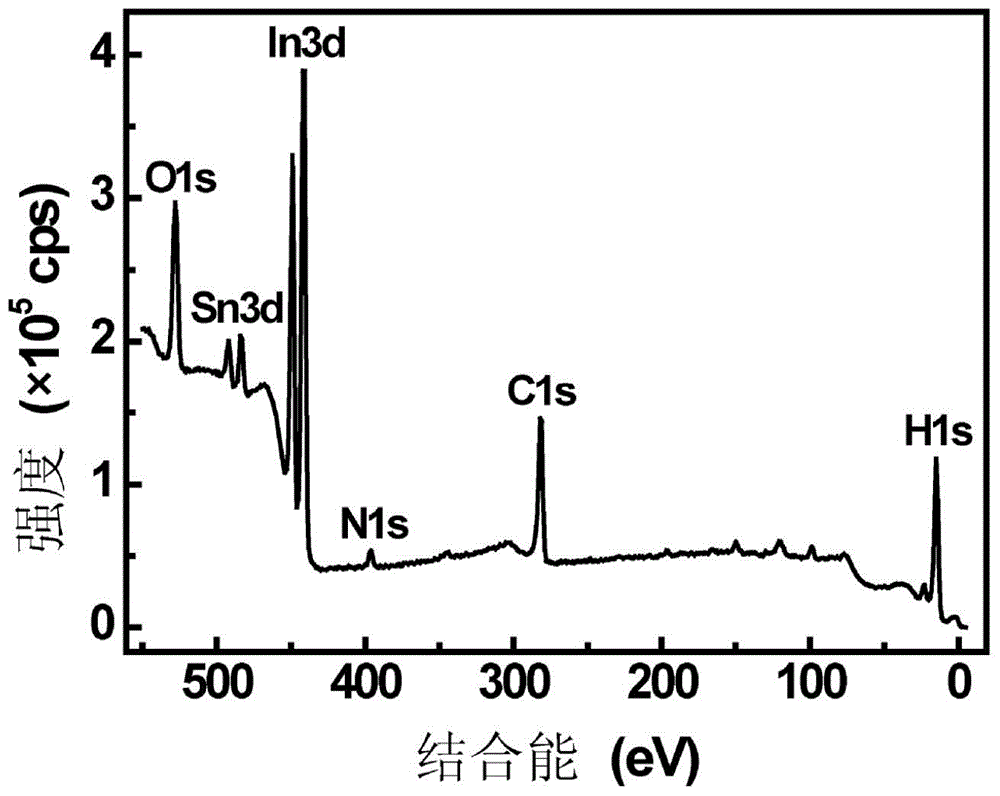

Preparation method of electrochromic polyaniline derivative film in covalent bond with ITO (indium tin oxide)

An electrochromic and covalent bond technology, applied in the direction of coating, etc., can solve the problem that the adhesion force is not as strong as the covalent bond, and achieve the effect of easy to master the operation process, fast response speed and tight combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Preparation of polyaniline film covalently bonded to ITO glass surface:

[0028] (1) Pretreatment of ITO glass substrate

[0029] The ITO glass substrate was ultrasonically cleaned in acetone, ethanol, and ultrapure water in sequence, and then soaked in a mixed solution of methanol and ultrapure water containing potassium carbonate for 30 min. The concentration of potassium carbonate was 0.5mol L -1 . After the ITO glass is washed with a large amount of ultrapure water, it is heated to 60°C in a solution with a volume ratio of 1:2:10 (28wt% ammonia water: 30wt% hydrogen peroxide: ultrapure water) and kept for 1 hour to make the surface of the ITO glass hydroxylated. . After rinsing with deionized water and drying, the surface hydroxylated ITO substrate was obtained.

[0030] (2) ITO glass surface modification

[0031] 50 ml of tetrahydrofuran was added to a 100 ml beaker, and the temperature was raised to 40°C. Add an appropriate amount of 4-aminobenzylphosphonic a...

Embodiment 2

[0037] Preparation of poly-o-methoxyaniline film covalently bonded to ITO substrate:

[0038] (1) Pretreatment of ITO glass substrate

[0039] The ITO glass substrate was ultrasonically cleaned in acetone, ethanol, and ultrapure water in sequence, and then soaked in a mixed solution of methanol and ultrapure water containing potassium carbonate for 30 min. The concentration of potassium carbonate was 0.5mol L -1 . After the ITO glass is washed with a large amount of ultrapure water, it is heated to 60°C in a solution with a volume ratio of 1:2:10 (28wt% ammonia water: 30wt% hydrogen peroxide: ultrapure water) and kept for 1 hour to make the surface of the ITO glass hydroxylated. . After rinsing with deionized water and drying, the surface hydroxylated ITO substrate was obtained.

[0040] (2) ITO glass surface modification

[0041] Add 50ml of toluene into a 100ml beaker, and control the temperature at 25°C. Add an appropriate amount of anilinomethyltriethoxysilane to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com