Multi-functional composite membrane with high photo-thermal conversion efficiency as well as preparation method and application of composite membrane

A composite film and conjugated polymer technology, applied in the field of multifunctional composite film and its preparation, can solve the problems of low-cost films and achieve high light-to-heat conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Preparation and application of PEDOT multifunctional composite membrane

[0028] Preparation of multifunctional composite membrane: 1 part by mass of poly-3,4-ethylenedioxythiophene (PEDOT) conjugated polymer nanoparticles (with a particle size of 15 nm), 99 parts of polyurethane and 24.1 parts of (the auxiliary agent is made up of plasticizer dioctyl phthalate, stabilizer calcium-zinc stabilizer, lubricant monoglyceride stearate and filler talcum powder, and its corresponding mass ratio is 20:1.5: 0.6:2) mixed and stirred evenly, and formed into a composite film by conventional extrusion method (which is characterized by a small production line area, low investment, simple equipment structure, simple operation, and easy production technology; among them, blow molding composite film is used. The film is cylindrical, and there is no need to cut edges, less waste is produced, and the thickness and width of the film are relatively easy to control), and the avera...

Embodiment 2

[0031] Embodiment 2: the preparation and application of multifunctional composite film

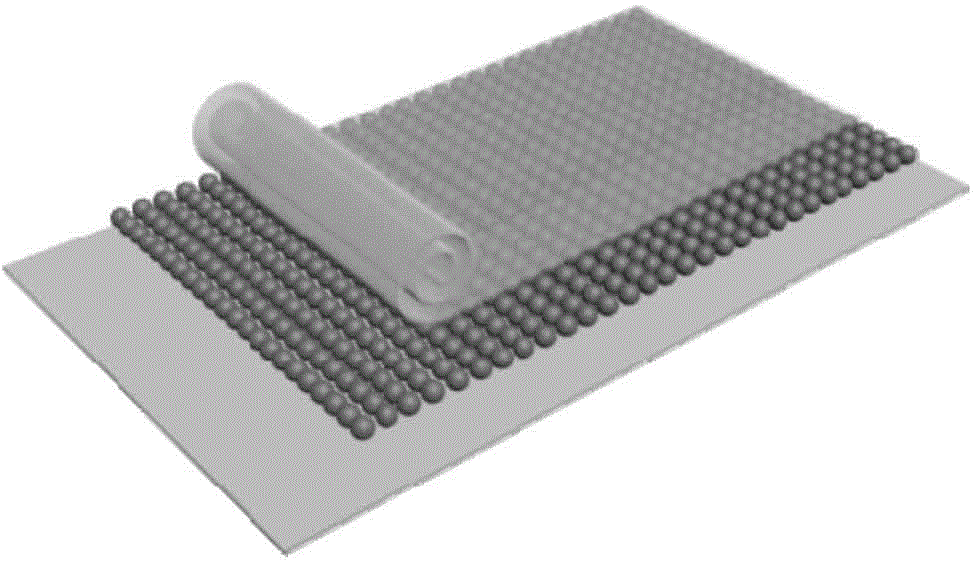

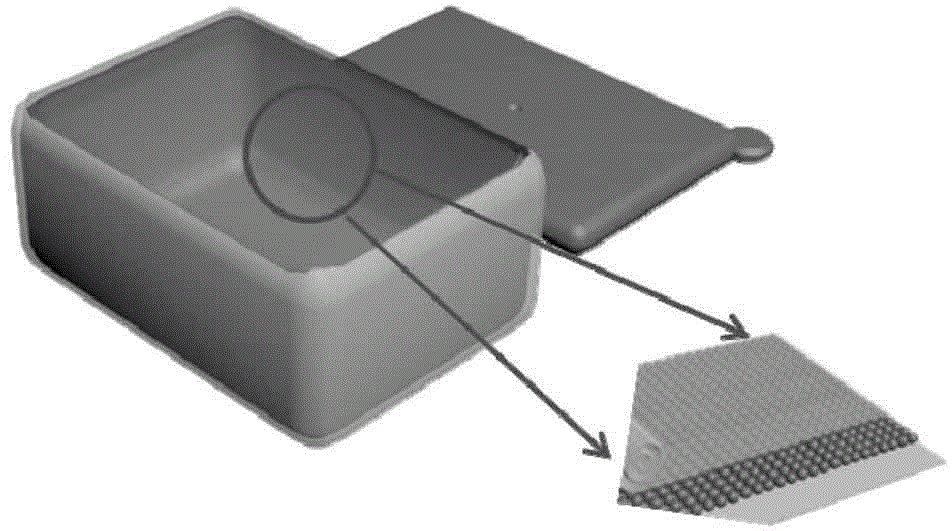

[0032] The preparation of multifunctional composite film: the polypyrrole (PPy) conjugated polymer nanoparticle (particle diameter is 20nm) of 5 parts by mass, the polyvinyl chloride (PVC) of 95 parts and the auxiliary agent of 28.2 parts ( The auxiliary agent is composed of plasticizer dioctyl phthalate, stabilizer calcium-zinc stabilizer, lubricant monoglyceride stearate and filler talcum powder, and its corresponding mass ratio is 23:2:0.7: 2.5) Mix and stir evenly, adopt conventional extrusion method to form a composite film, and the average film thickness of the multifunctional composite film is 0.9mm. The schematic diagram of the prepared multifunctional composite membrane is shown in figure 1 shown. From figure 1 It can be known that the multifunctional composite film is not a single layer film.

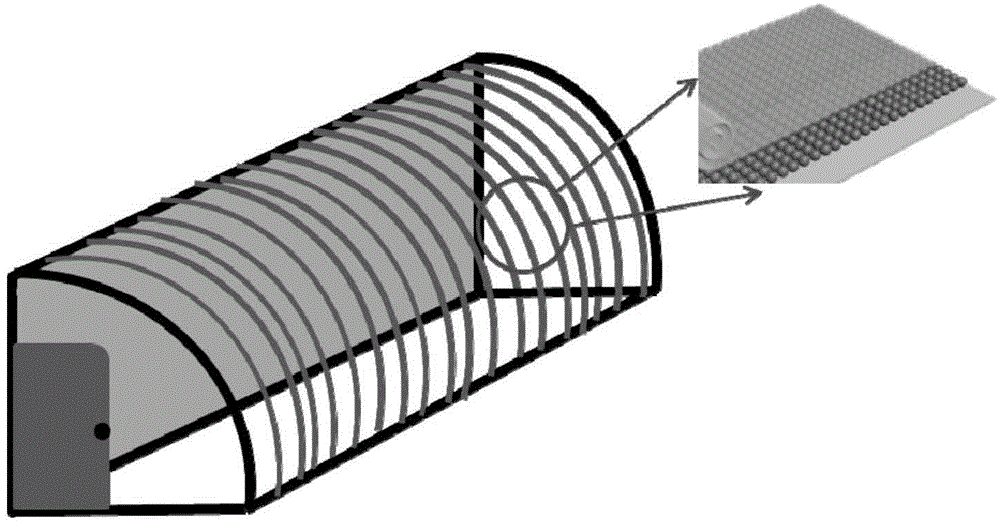

[0033] Application of multifunctional composite film: apply the prepared multifunc...

Embodiment 3

[0035] Embodiment 3: the preparation and application of multifunctional composite film

[0036] The preparation of multifunctional composite film: the polypyrrole (PPy) conjugated polymer nanoparticle (particle diameter is 30nm) of 13 parts by mass, the polyethylene (PE) of 87 parts and the auxiliary agent of 25.1 parts (the described The auxiliary agent is composed of plasticizer dioctyl phthalate, stabilizer calcium-zinc stabilizer, lubricant PE wax and filler talc powder, and the corresponding mass ratio is (21:2.1:0.5:1.5) mixed and stirred evenly , the conventional calendering method is used to form the composite film (its characteristic is that the production speed of the calender is fast, the film produced has high working strength, good quality, and small thickness error), and the film thickness of the multifunctional composite film is 0.3mm.

[0037] The schematic diagram of the prepared multifunctional composite membrane is shown in figure 1 shown.

[0038] Applica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com