Microcapsule purification method and application of dill oil for cigarettes

A purification method and technology of dill oil, which is applied in the field of microcapsule purification of dill oil for cigarettes, can solve problems such as decomposition, polymerization and configuration transformation of active ingredients, affecting the aroma of dill oil, and residues in the mouth of cigarettes. Visible, mild, natural-scented results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

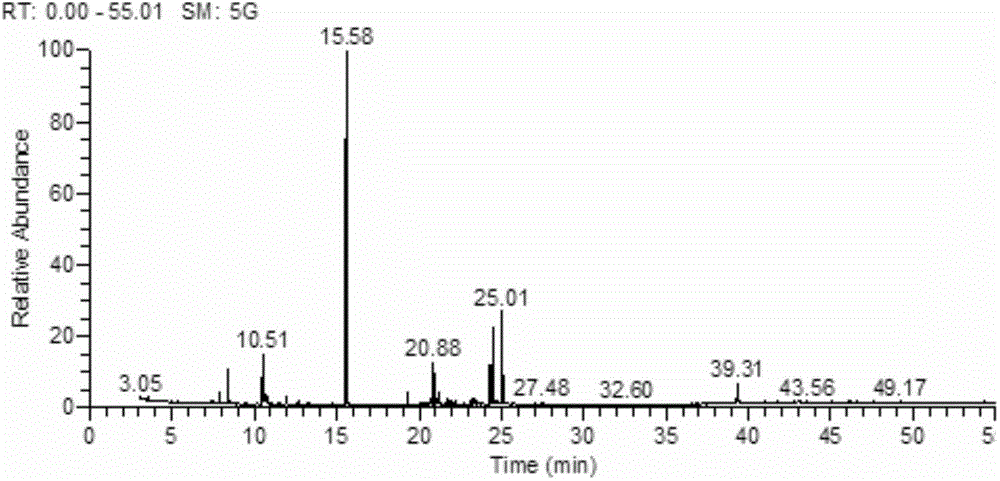

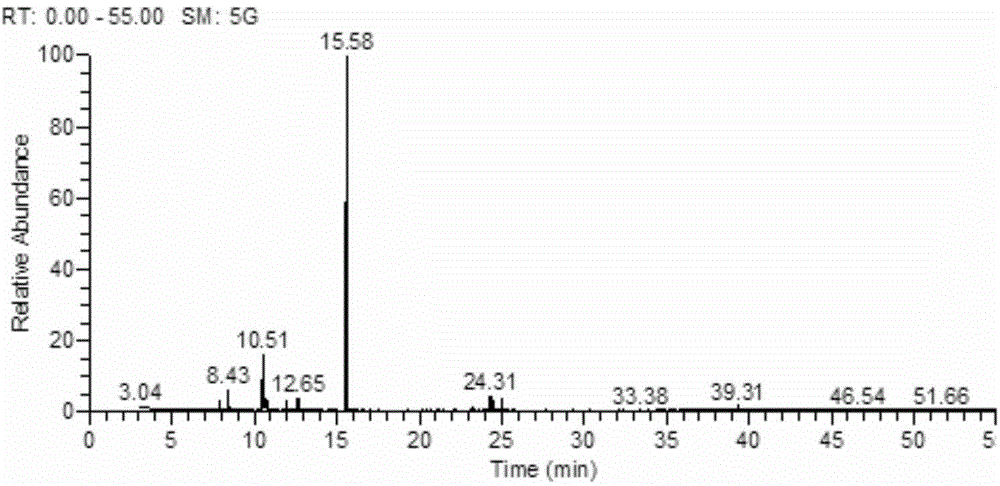

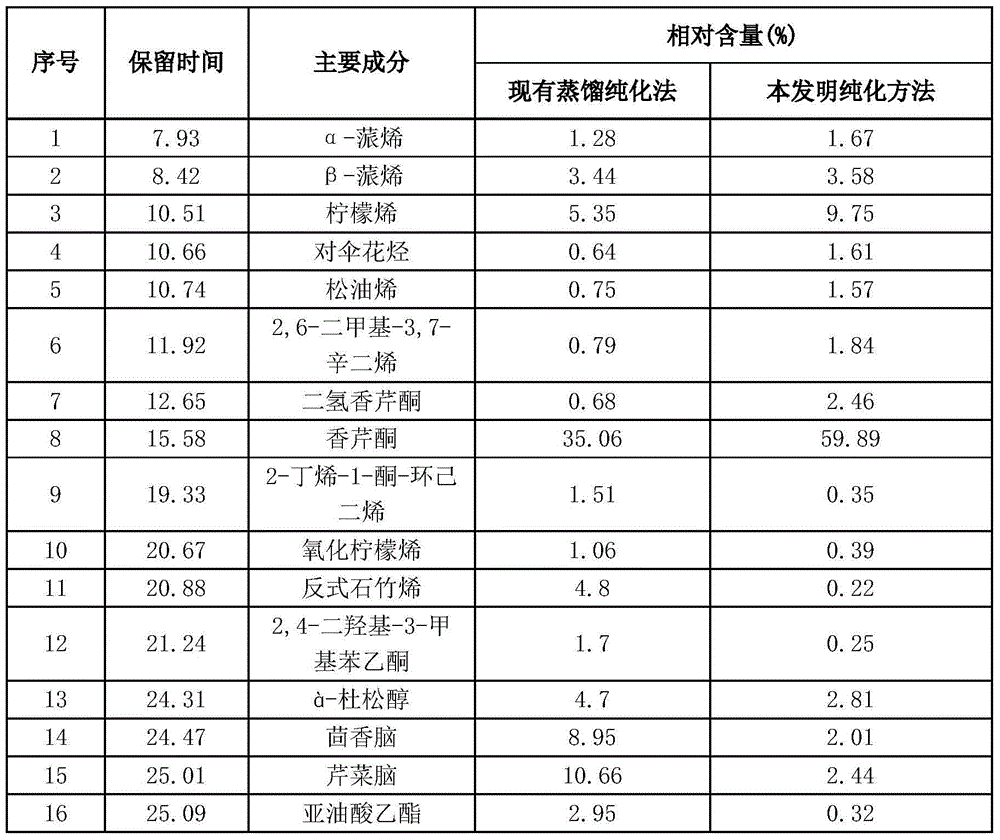

Image

Examples

Embodiment 1

[0027] (1) steam distillation obtains dill oil;

[0028] (2) Dill oil is diluted with 30% aqueous ethanol in a ratio of 1:15 (g:mL);

[0029] (3) Add 40% food-grade β-cyclodextrin vesicle wall material and 5% food-grade sodium sulfate in the diluent;

[0030] (4) Stir evenly in a constant temperature water bath at 45°C, let it stand for stratification after uniformity, and at this time, the dextrin layer can be made into microcapsule products;

[0031] (5) Continue to add 2 times the volume of absolute ethanol to the dextrin phase, stir fully, and release the capsule core;

[0032] (6) centrifuge, get ethanol layer;

[0033] (7) Distill the ethanol layer under reduced pressure to reclaim ethanol to obtain dill oil.

Embodiment 2

[0035] (1) Use 40% ethanol aqueous solution as a solvent, soak the dill raw material for 24 hours according to the raw material and solvent 1:20 (g:mL), to obtain dill extract;

[0036] (2) adding 40% food-grade β-cyclodextrin vesicle wall material and 10% food-grade sodium chloride to the extract;

[0037] (3) Stir evenly in a constant temperature water bath at 60°C, let it stand for stratification after uniformity, and at this time, the dextrin layer can be made into microcapsule products;

[0038] (4) Continue to add 4 times the volume of absolute ethanol to the dextrin phase, fully stir, and release the capsule core;

[0039] (5) centrifuge, get ethanol layer;

[0040] (6) Distill the ethanol layer under reduced pressure to reclaim ethanol to obtain dill oil.

Embodiment 3

[0042] (1) supercritical extraction obtains dill oil;

[0043] (2) Dill oil is diluted with 45% aqueous ethanol in a ratio of 1:3 (g:mL);

[0044] (3) Add 30% food-grade gamma-cyclodextrin vesicle wall material and 20% food-grade sodium carbonate in the diluent;

[0045] (4) Stir evenly in a constant temperature water bath at 40°C, let it stand for stratification after uniformity, and at this time, the dextrin layer can be made into microcapsule products;

[0046] (5) Continue to add 6 times the volume of absolute ethanol to the dextrin phase, stir fully, and release the capsule core;

[0047] (6) centrifuge, get ethanol layer;

[0048] (7) Distill the ethanol layer under reduced pressure to reclaim ethanol to obtain dill oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com