Double-ligand zinc complex catalyst and application thereof

A technology of zinc complexes and catalysts, applied in the direction of organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, zinc organic compounds, etc., can solve poor corrosion and water resistance, slow release of corrosion inhibitors Poor performance, expensive and other problems, to achieve the effect of reducing corrosion and water resistance, easy recycling, and less by-product high polymer generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

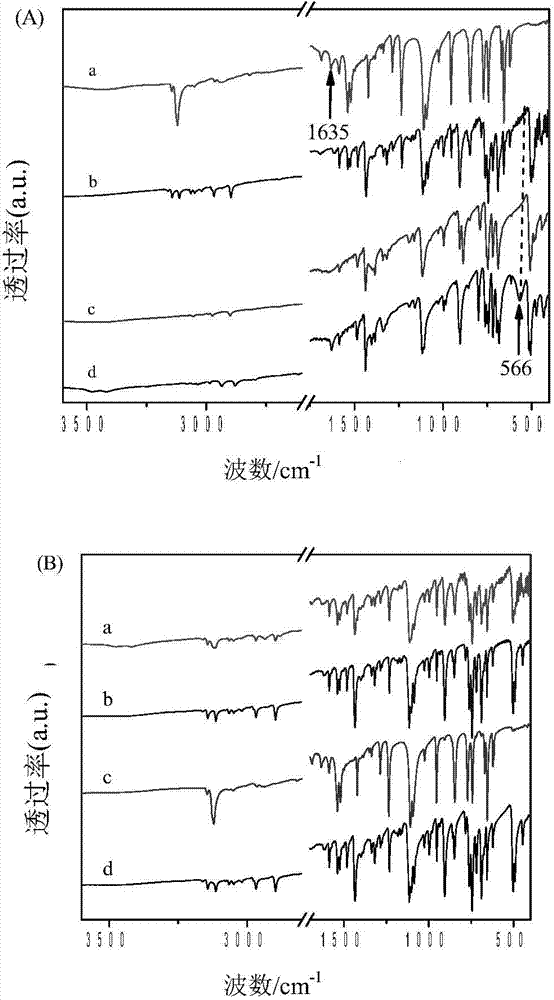

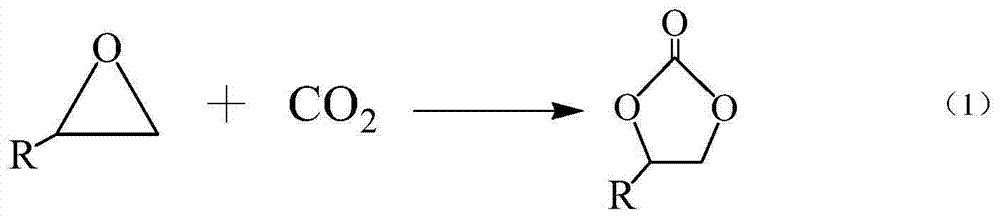

Method used

Image

Examples

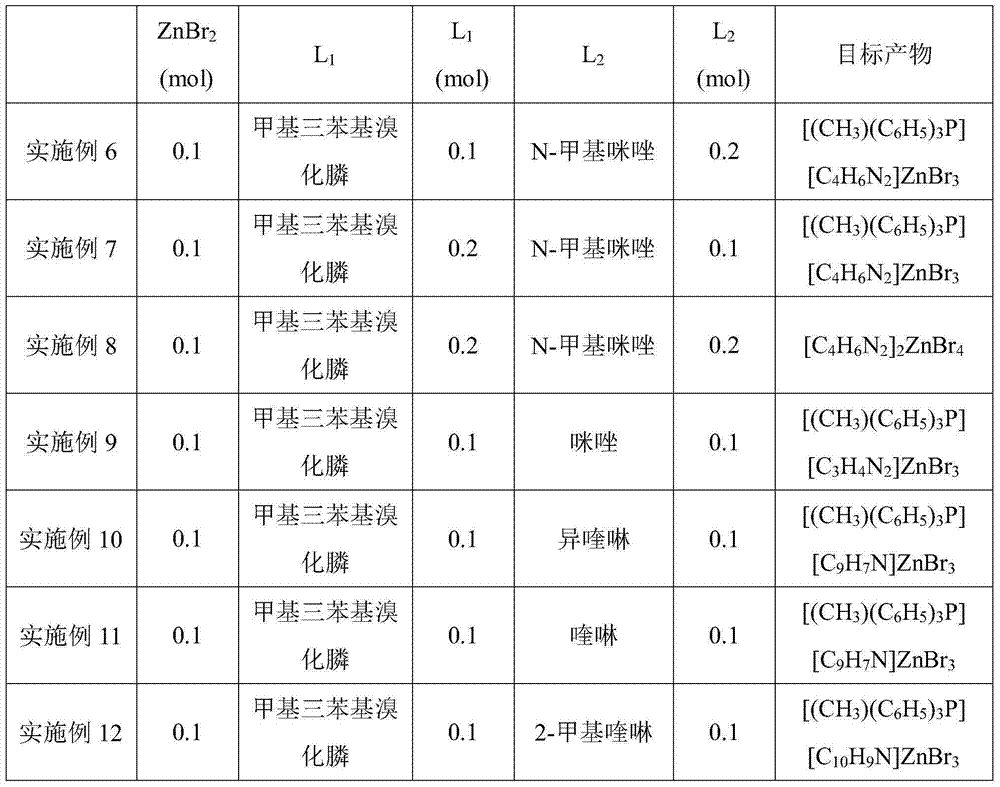

Embodiment 1

[0040] Weigh 0.1mol ZnBr 2 Dissolve in 100mL of absolute ethanol, 0.1mol of methyltriphenylphosphonium bromide in 25ml of absolute ethanol, and 0.1mol of N-methylimidazole in 25mL of absolute ethanol. Add ZnBr to phosphine solution 2 After adding N-methylimidazole solution to the above-mentioned mixture, the mixture is prepared by heating and boiling to 50°C and maintaining it for about 30 minutes, cooling to room temperature, filtering, and drying at 60°C under vacuum to obtain white Powdery complex [(CH 3 )(C 6 H 5 ) 3 P][C 4 H 6 N 2 ]ZnBr 3 catalyst.

Embodiment 2

[0042] Under the conditions of implementation case 1, weigh out 0.1 mol ZnI 2 Dissolved in 100mL of absolute ethanol, 0.1mol of tetraphenylphosphine iodide dissolved in 25ml of absolute ethanol, a white powdery complex [(C 6 H 5 ) 4 P][C 4 H 6 N 2 ]ZnI 3 catalyst.

Embodiment 3

[0044] 3mmol prepared in Example 1 [(CH 3 )(C 6 H 5 ) 3 P][C 4 H 6 N 2 ]ZnBr 3 The complex was dissolved in 0.5 mol of reactant propylene oxide, and added to the reaction kettle, sealed and stirred to make it fully mixed, and pass CO 2 Replace the air 2 to 3 times, then pass in CO 2 The gas maintains a pressure of 2.5MPa, and the temperature is raised to 100℃ to react for 30 minutes. During the reaction, when the pressure is lower than 4MPa, CO is added 2 To 4MPa, until the kettle pressure remains unchanged; cooling, removing the kettle liquid, using vacuum distillation to obtain the propylene carbonate product, weighing, measuring its pH with a pH meter to be 7.75, and analyzing the yield of propylene carbonate by gas chromatography to be 99.2 %; On this basis, the product of propylene carbonate was separated by vacuum distillation, and the catalyst was recycled for 10 times. The yield of propylene carbonate was greater than 95%; and through gas chromatography analysis, no glycol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com