Preparation method of 3-methyl-4-oxo-4-(p-amino)phenylbutyric acid

A technology of phenylbutyric acid and p-amino, which is applied in the field of preparation of 3-methyl-4-oxo-4-(p-amino)phenylbutyric acid, can solve the problem of complex post-treatment process, high waste removal cost, High cost of raw materials and other issues, to achieve the effect of novel process design, safe and simple operation, and environmentally friendly reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

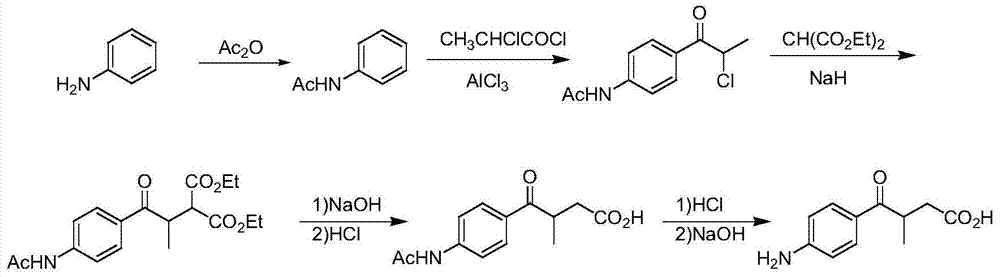

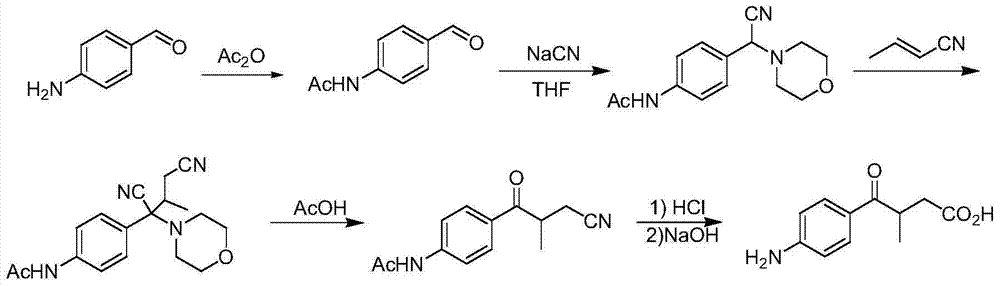

Method used

Image

Examples

Embodiment 1

[0033] 500g of p-nitrobenzoic acid (I) was added with 2.7kg of dichloromethane, and then 435g of propylmalonate, 550g of N,N-lutidine and 1.06kg of dicyclohexyl carbon two were added successively Imine, the reaction temperature is 10℃, after 36 hours of reaction, filter out the insoluble solids, add 420 ml of 1N hydrochloric acid to the organic phase, stir thoroughly, and dry the separated organic phase with sodium sulfate for 5 hours, then filter out Sodium sulfate, it is recommended to distill off the organic solvent to obtain 855kg of intermediate (II).

[0034] Add 2200g of DMF to 855g of intermediate (II), control the temperature of the mixed solution to 0°C with an ice-water bath, then add 200g of sodium ethoxide to the mixed solution, then control the temperature of the reaction solution at -5°C, and add 460g dropwise The reaction temperature is -5℃. After 13 hours of reaction, the DMF is distilled off under reduced pressure, and then methyl tert-butyl ether is added; the ...

Embodiment 2

[0040] Add 3kg of dichloromethane to 600g of p-nitrobenzoic acid (I), then add 530kg of propylmalonate, 520g of N,N-lutidine and 1500g of dicyclohexylcarbodiimide. , The reaction temperature is 20 ℃, after 16 hours of reaction, filter out the insoluble solids, add 5 liters of 1N hydrochloric acid to the organic phase, after fully stirring, the separated organic phase is dried with sodium sulfate for 4 hours, then the sodium sulfate is filtered out It is recommended to distill off the organic solvent to obtain 1033g of intermediate (II).

[0041] Add 2.4kg of DMF to 1033g of intermediate (II), control the temperature of the mixed solution with an ice-water bath to 20°C, then add 290g of sodium ethoxide to the mixed solution, control the temperature of the reaction solution at 0°C, and add 540g dropwise The reaction temperature is 5℃. After 10 hours of reaction, the DMF is distilled off under reduced pressure, and then methyl tert-butyl ether is added; the temperature of the soluti...

Embodiment 3

[0047] Add 15 kg of dichloromethane to 3 kg of p-nitrobenzoic acid (I), then add 2.6 kg of propyl malonate, 3.1 kg of N,N-lutidine and 7.4 kg of dicyclohexyl carbon. Diimine, the reaction temperature is 28 ℃, after 32 hours of reaction, filter out the insoluble solids, add 25 liters of 1N hydrochloric acid to the organic phase, after fully stirring, the separated organic phase is dried with sodium sulfate for 5 hours, then filtered After sodium sulfate is removed, it is recommended to distill off the organic solvent to obtain 5.15 kg of intermediate (II).

[0048] Add 12kg of DMF to 5.15kg of intermediate (II), control the temperature of the mixed solution to 10℃ in an ice-water bath, then add 1.44kg of sodium ethoxide to the mixed solution, and then control the temperature of the reaction solution at -5℃. Add 2.74kg of methyl iodide and drip it in about 1 hour. The reaction temperature is 0°C. After 12 hours of reaction, the DMF is evaporated under reduced pressure, and then met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com