Production method of compound multi-microorganism functional bacterium solution

A production method and technology of functional bacteria, applied in the field of brewing, can solve the problems of not being able to give full play to the performance of brewing functional bacteria, the ineffective complementation of enzyme systems and flavor substances, and the low conversion rate of medium, so as to improve the quality and yield of high-quality base wine , Improve the quality of seasoning wine and the output of high-quality base wine, and the effect of prominent base wine aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

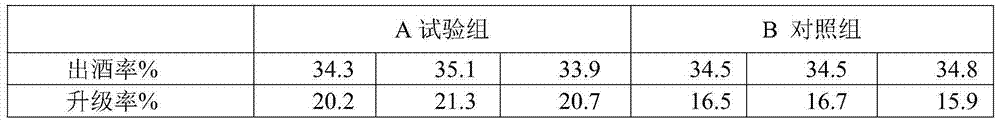

Examples

Embodiment 1

[0040] Embodiment 1: According to the following steps to produce composite multi-microfunctional bacterial liquid

[0041] (1) Preparation of bacterial seed solution: firstly, 10 strains of bacterial functional bacteria screened from soft liquor brewing environment were activated on a slant, and secondly, a circle of activated bacteria was cultured in beef extract peptone liquid with a pH value of 6.5 Carry out pure-bred liquid culture in medium (300mL / 500mL), control the shaker speed at 80r / min, temperature 40°C, and cultivate for 20h to obtain pure-bred functional bacterial seed liquid, and the number of bacterial cells per ml is kept at 10 8 A / mL or so;

[0042] (2) Preparation of aroma yeast seed liquid: firstly, 11 strains of yeast functional bacteria screened from the soft liquor brewing environment were activated on a slant, and secondly, a ring of aroma yeast was soaked in wort powder liquid with a pH value of 3.5 Carry out purebred liquid culture in medium (300mL / 500...

Embodiment 2

[0046] Embodiment 2: According to the following steps to produce composite multi-microfunctional bacterial liquid

[0047] (1) Preparation of bacterial seed liquid: first, 5 strains of functional bacteria: Bacillus subtilis (CCTCCAB130016), Bacillus coagulans (CCTCCAB92066), Bacillus licheniformis (CCTCCAB91060), Paenibacillus polymyxa (CGMCC1.2979), circular Bacillus (CCTCCAB207850) was activated on a slant, followed by taking a ring of activated bacteria and carrying out purebred liquid culture in beef extract peptone liquid medium (300mL / 500mL) with a pH value of 7.0. ℃, cultured for 24 hours, to obtain a pure functional bacterial seed solution, and the number of bacteria per milliliter was kept at 10 7 more than one / mL;

[0048] (2) Preparation of the seed liquid of Aromatoyces cerevisiae: firstly, slant the 6 strains of functional yeast: Candida (CCTCCAY91001), Hansenula (CCTCCAY92053, CCTCCAY93047), Pichia pastoris (CCTCCAY201001), Saccharomyces cerevisiae (CCTCCAY20001...

Embodiment 3

[0052] Embodiment 3: according to the following steps to produce composite multi-microfunctional bacterial liquid

[0053] (1) Preparation of bacterial seed liquid: first, 10 strains of functional bacteria were activated on a slant, and secondly, a ring of bacteria after activation was respectively taken to carry out pure-blood liquid culture in beef extract peptone liquid medium (300mL / 500mL) with a pH value of 7.5, Control the rotation speed of the shaker at 100r / min, the temperature at 30°C, and cultivate for 24 hours to obtain a pure functional bacterial seed solution, and the number of bacteria per ml is kept at 10 8 A / mL or so;

[0054] (2) Preparation of Aroma Yeast Seed Solution: Firstly, 11 Aroma Yeast strains were activated on a slant, and then a ring of Aroma Yeast was respectively taken in a liquid culture medium (300mL / 500mL) with a pH value of 5.5 for pure-breeding Aroma Yeast. Cultivation, controlled shaker speed 80r / min, temperature 37°C, cultured for 24 hours...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com