Method utilizing polylactic acid/carbon nanotube composite electro-spun fiber membrane to absorb and remove perfluorooctane sulfonate in water

A carbon nanotube composite and perfluorooctane sulfonic acid technology, which is applied in the direction of adsorption of water/sewage treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of unsatisfactory adsorption efficiency of electrospun fiber membranes, and achieve Facilitate rapid placement, mild conditions and strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

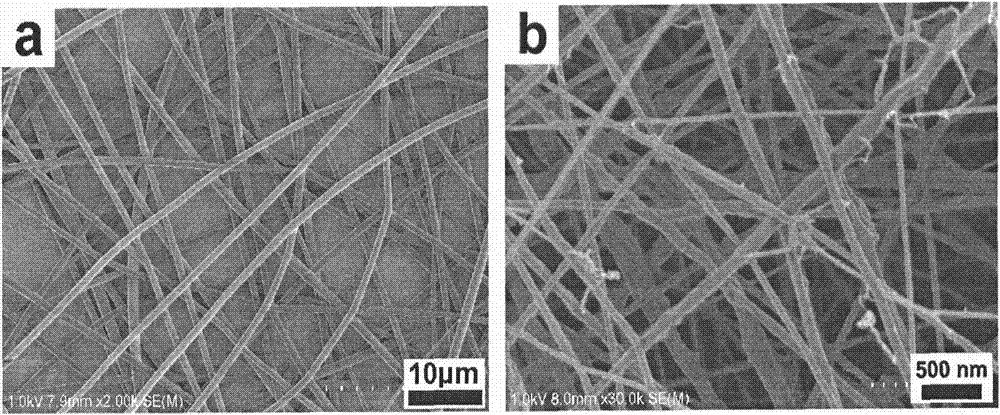

Embodiment 1

[0042] First, 3 g of polylactic acid with a molecular weight of 100,000 was added to a glass Erlenmeyer flask filled with 20 g of methylene chloride solution. After mixing, it was placed on a magnetic stirrer and stirred at room temperature for 3 hours to obtain a transparent gel solution. Weigh 50 mg of acidified multi-walled carbon nanotubes and add them into 5 mL of dichloromethane, and sonicate for 10 minutes under the condition of 20 kHz in a digitally controlled ultrasonic instrument, so that the multi-walled carbon nanotubes are evenly dispersed in dichloromethane, and carbon nanotubes- Dichloromethane dispersion. Then take a certain amount of dispersion liquid and add it to the polymer transparent gel solution, mix it on a vortex mixer for 5 minutes (1000 rpm), and then ultrasonicate it for 10 minutes to make a uniform carbon nanotube / polymer mixed gel. The mixed gel was introduced into the spinneret of the electrospinning device, the flow rate of the spinning solution...

Embodiment 2

[0045] The preparation steps of the polylactic acid / carbon nanotube composite electrospun fiber membrane are the same as in Example 1.

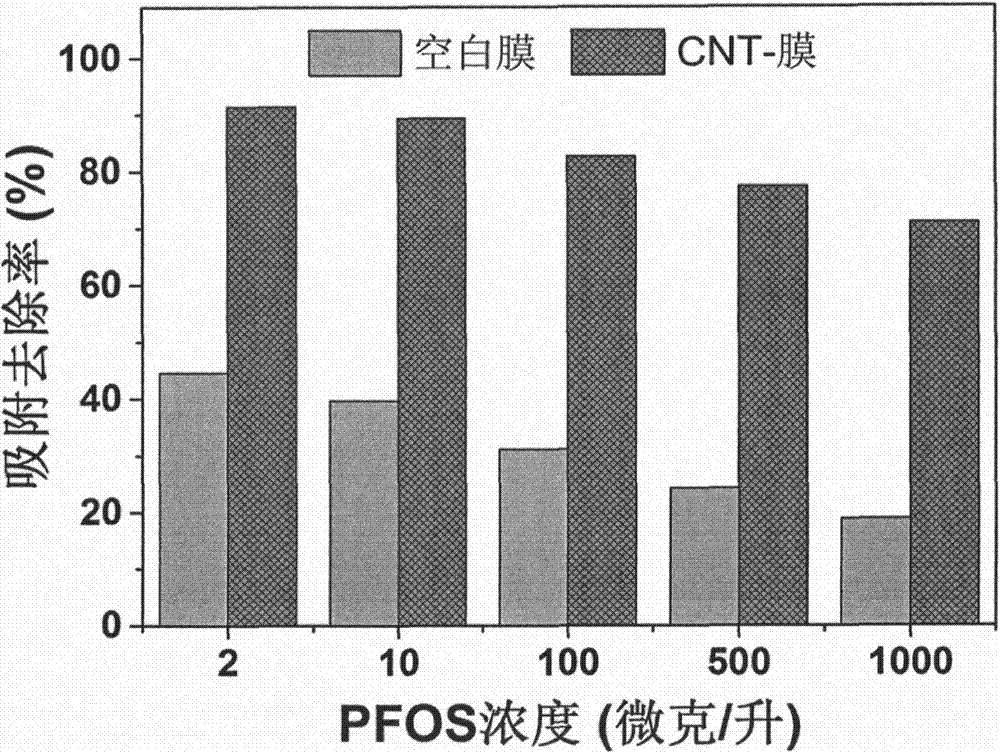

[0046] Cut the obtained polylactic acid / carbon nanotube composite electrospun fiber membrane into small squares of 1 cm×1 cm, and peel them off from the aluminum foil. Then weigh 50-55 mg (about 3 pieces) of polylactic acid / carbon nanotube composite electrospun fiber membrane and add it to 50 mL of PFOS aqueous solution with a concentration of 10 μg / L; and place the mixed system at 25 ° C and 150 rpm to vibrate and react. After 20 h of reaction, samples were taken and determined by high-performance liquid chromatography-mass spectrometry (HPLC-MS / MS, API3200, Applied Biosystems, USA). At the same time, a blank PLA electrospun fiber membrane was reacted under the same conditions as a control experiment. In this method, the adsorption and removal rate of PFOS by polylactic acid / carbon nanotube composite electrospun fiber membrane was 89.33%, w...

Embodiment 3

[0048] The preparation steps of the polylactic acid / carbon nanotube composite electrospun fiber membrane are the same as in Example 1.

[0049] Cut the obtained polylactic acid / carbon nanotube composite electrospun fiber membrane into small squares of 1 cm×1 cm, and peel them off from the aluminum foil. Then weigh 50-55 mg (about 3 pieces) of polylactic acid / carbon nanotube composite electrospun fiber membrane and add it to 50 mL of PFOS aqueous solution with a concentration of 100 μg / L; and place the mixed system at 25 ° C and 150 rpm to vibrate and react. After 20 h of reaction, samples were taken and determined by high-performance liquid chromatography-mass spectrometry (HPLC-MS / MS, API3200, Applied Biosystems, USA). At the same time, a blank PLA electrospun fiber membrane was reacted under the same conditions as a control experiment. In this method, the adsorption and removal rate of PFOS by PLA / carbon nanotube composite electrospun fiber membrane was 82.62%, while the ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com