Self-polishing antifouling fluorosilicone acrylate resin and preparation method thereof

A technology of fluorosilicone acrylic and antifouling resin, which is applied in the direction of antifouling/underwater coatings, coatings, paints containing biocide, etc., and can solve the problem of uncertain distribution of fluorosilicone, self-polishing characteristics and complex preparation process etc. to achieve the effects of uniform hydrolysis/degradation, anti-pollution, environmental friendliness, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1: Preparation of Fluorosilicone Acrylic Acid Monomer

[0018] First mix 12.4g of potassium methacrylate with 90ml of toluene, add 0.1g of 18-crown-6, stir evenly, put it into a round-bottom three-port reactor and place it in a water bath at 25°C; add 10.6g of trifluoropropylmethyl di Mix chlorosilane and 10.6g toluene evenly, put it into a constant pressure dropping funnel, drop it into a three-port reactor for 2 hours at a constant speed, and react for 24 hours to obtain a fluorosilicone acrylic acid monomer; its molecular structure is:

[0019]

Embodiment 2

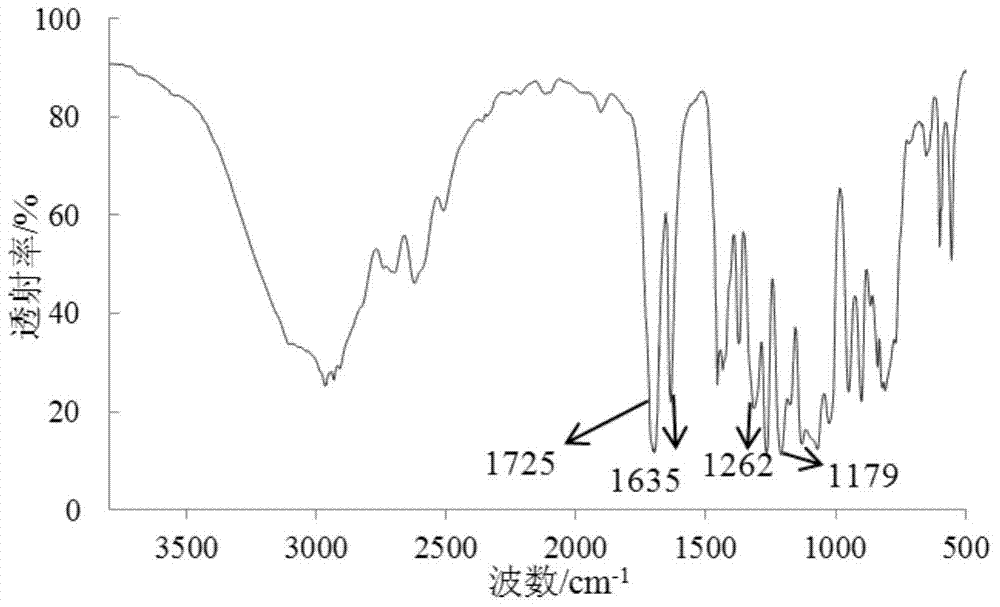

[0020] Example 2: Infrared Characterization of Fluorosilicone Acrylic Acid Monomer

[0021] Using red light spectrum test, the results are shown in the attached figure 1 : The methyl stretching vibration peak at 2954cm-1, the stretching vibration peak of methylene at 2876cm-1, the strong absorption peak at 1725cm-1 is the characteristic peak of the C=O double bond, and the strong absorption peak at 1635cm-1 C=C double bond characteristic absorption peak at 1262cm-1, Si-CH3 bond characteristic absorption peak at 1179cm-1, C-F stretching vibration peak at 1065cm-1, C-O bond characteristic absorption peak at 1065cm-1, There is a characteristic absorption peak of Si-O bond at 1022cm-1, an asymmetric stretching vibration absorption peak of Si-C bond and a characteristic absorption peak of -CH3 at 803cm-1.

Embodiment 3

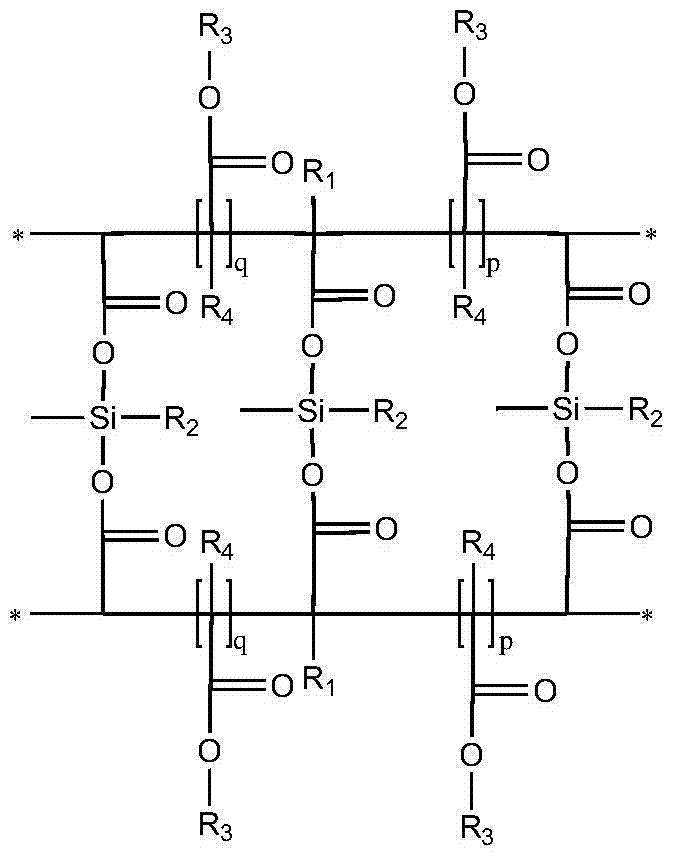

[0022] Example 3: Preparation of Fluorosilicone Acrylic Hydrolyzable / Degradable Self-Polishing Antifouling Resin

[0023] Stir and mix 2 g of the fluorosilicon acrylic acid monomer obtained in Example 1, 2 g of methyl methacrylate, 6 g of butyl acrylate and 40 g of toluene, add 0.1 g of azobisisobutyronitrile, and stir the reaction at a temperature of 85°C After 4 hours, a colorless and transparent fluorosilicone acrylic acid hydrolyzable / degradable self-polishing antifouling resin was obtained, and its molecular structural formula is:

[0024]

[0025] The glass transition temperature was -5°C tested by TG-DSC thermogravimetric analysis, and the molecular weight distribution was tested by GPC. The mass average relative molecular mass Mw was 8800, the number average relative molecular mass Mn was 4800, and the dispersion coefficient Mw / Mn was 1.84.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com