Non-saponification extraction separation method of rare-earth element

A rare earth element, non-saponification technology, applied in the field of collaborative extraction and separation of rare earth elements, can solve the problems of reducing the concentration of hydrogen ions, reducing the concentration of rare earth material liquid, and not being able to adjust the acidity of the water phase, and achieve the effect of solving environmental pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

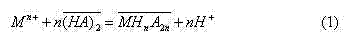

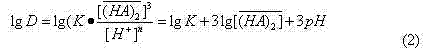

Method used

Image

Examples

Embodiment 1

[0037] The raw material is mixed rare earth carbonate as raw material, and dissolved with 3mol / L hydrochloric acid to obtain a rare earth chloride solution. The total concentration of rare earth elements in the rare earth chloride solution is REO=250g / L, and the distribution of rare earth elements is calculated as oxides. The percentage of the ratio of element mass to total rare earth element oxide REO mass is: La 2 o 3 / REO=26.75%; CeO 2 / REO =50.00%; Pr 6 o 11 =5.50% / REO; Nd 2 o 3 / REO =15.50%; medium and heavy rare earths (calculated as oxides) / REO =2.25%. , adjusting the pH of the rare earth aqueous solution to 1.0-1.4.

[0038]The organic phase is unsaponified P507 mixed with N1923 to form a synergistic extractant and sulfonated kerosene to form an organic solution according to a certain volume ratio, wherein the volume fraction of P507 in the synergistic extractant is 50%, the volume fraction of N1923 is 50%, and the synergistic extractant Mix it with kerosene ...

Embodiment 2

[0042] The raw material is mixed rare earth oxide, and the mixed rare earth oxide is dissolved with hydrochloric acid to a total concentration of REO=35g / L containing rare earth elements. The distribution of rare earth elements is the same as in Example 1, and the pH of the rare earth aqueous solution is adjusted to 0-0.8.

[0043] The organic phase is unsaponified P204 mixed with N179 to form a synergistic extractant and carbon tetrachloride to form an organic solution according to a certain volume ratio, wherein the volume fraction of P204 in the synergistic extractant is 65%, and the volume fraction of N179 is 35%. The solvent and carbon tetrachloride are mixed into an organic phase according to the volume ratio of 2:1, and after reacting with 3mol / L hydrochloric acid in a volume ratio of 1:1, they are washed with water until neutral to become the extracted organic phase. Use 18-stage countercurrent method to extract all rare earth elements, compared (unit L / min): organic ph...

Embodiment 3

[0045] The raw material is a mixed rare earth chloride solution, the total concentration of rare earth elements contained in the mixed rare earth chloride solution REO=200g / L, and the distribution of rare earth elements is the difference between the mass of each rare earth element and the mass of total rare earth element oxides REO in terms of oxides. The percentage ratio is: La 2 o 3 / REO=51.0%; CeO 2 / REO =17.0%; Pr 6 o 11 =10.0% / REO; Nd 2 o 3 / REO =20.0%; medium and heavy rare earths (calculated as oxides) / REO =2.0%. , adjust the pH of the rare earth aqueous solution to 3-4.

[0046] The organic phase is unsaponified naphthenic acid mixed with N116 to form a synergistic extractant and cyclohexane to form an organic solution according to a certain volume ratio, wherein the volume fraction of naphthenic acid in the synergistic extractant is 70%, and the volume fraction of N116 is 30%. The synergistic extractant and kerosene are mixed into an organic phase at a volume ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com