Base for artificial leather

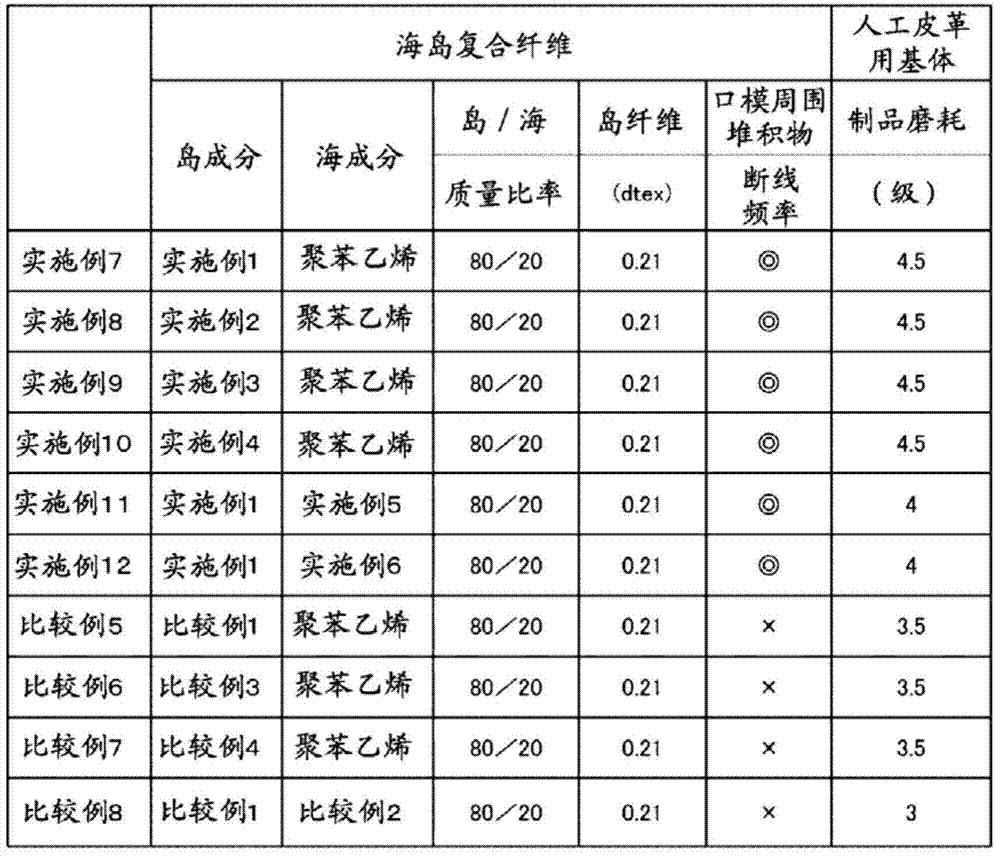

An artificial leather and matrix technology, which is applied in the direction of single-component copolyester rayon, conjugated synthetic polymer rayon, non-woven fabric, etc. , polymer yellowing and other problems, to achieve the effect of excellent wear resistance, increased production efficiency, and less decrease in intrinsic viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

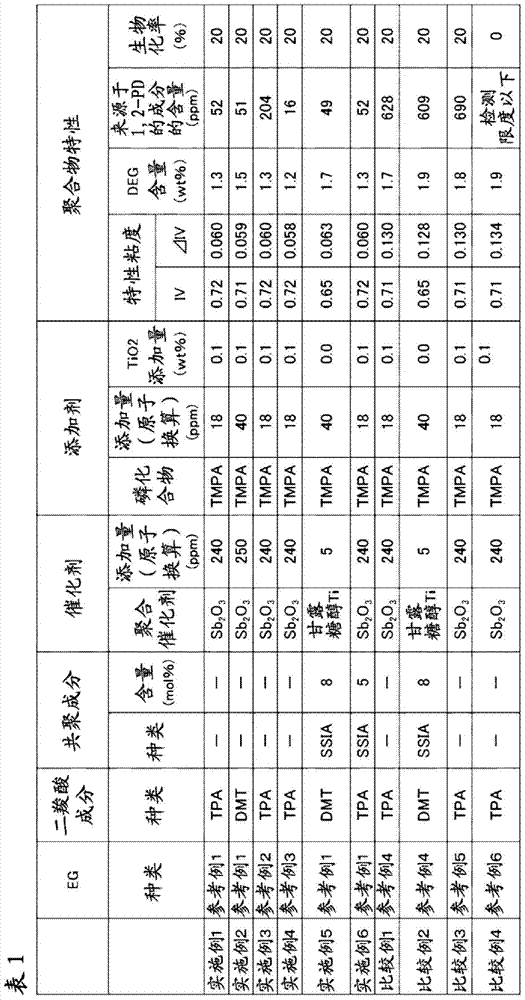

[0094] Next, the present invention will be described in more detail by giving experimental examples and examples. However, the present invention is not limited to these examples, and various modifications and corrections are possible without departing from the technical scope of the present invention.

[0095] [Materials used for polymerization]

[0096] ·Ethylene glycol from biomass resources: Manufactured by Changchun Dacheng Group

[0097] (Ethylene glycol=98.138% by weight, 1,2-propanediol=5410ppm, 1,2-butanediol=2390ppm, 2,3-butanediol=6310ppm, 1,4-butanediol=4510ppm).

[0098] - Ethylene glycol derived from fossil resources: manufactured by Mitsubishi Chemical Corporation.

[0099] (Ethylene glycol=99.989% by weight, 1,2-propanediol<15ppm (not detectable), diethylene glycol=110ppm)

[0100] · Terephthalic acid: high-purity terephthalic acid (1,2-propanediol < 15ppm (not detectable)) manufactured by Mitsui Chemicals

[0101] ・Dimethyl terephthalate: SK Chemical Co., Lt...

reference example 1

[0147] For the obtained 20kg of ethylene glycol derived from biomass resources, as a distillation operation, distillation is carried out under the conditions of 40 stages of theoretical plate number, pressure 50mmHg, and reflux ratio of 10, and crude ethylene glycol (containing 1,2-propanediol: 3520ppm). The obtained crude ethylene glycol was heated in a heating tank with a set temperature of 190° C. for 15 hours, and then cooled to room temperature.

[0148] On the other hand, activated carbon (manufactured by Futamura Chemical Industry Co., Ltd.: Taiko SGA) was washed with soft water and dried, and the dried activated carbon was filled in an activated carbon treatment facility. The thickness of the activated carbon layer is 300cm and the space velocity is 0.57hr -1 , The ethylene glycol derived from the biomass resource that has been cooled after the above-mentioned heating flows into the activated carbon layer and is collected. Biomass resource-derived ethylene glycol (re...

reference example 2

[0150] Set the thickness of the activated carbon layer to 200cm and the space velocity to 0.86hr -1 , except that, in the same manner as in Reference Example 1, biomass resource-derived ethylene glycol (refined product) with a 1,2-propanediol content of 910 ppm was finally obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com