A kind of insecticidal composition for controlling rice and vegetables Lepidoptera and Homoptera pests

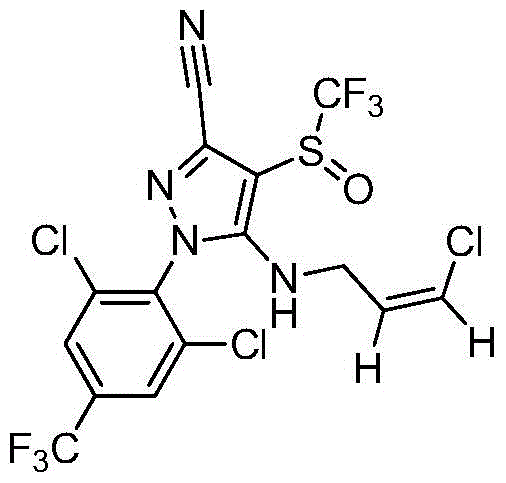

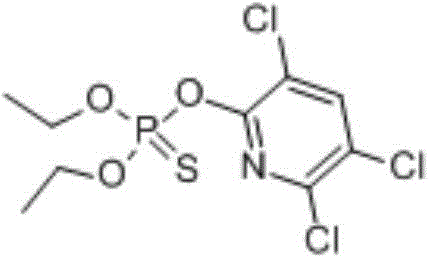

An insecticidal composition and lepidopteran technology, applied in the directions of insecticides, biocides, animal repellents, etc., can solve the problems of HNPC-A8008, chlorpyrifos mixing, etc., and reduce the risk of drug resistance and pesticides. The amount of use and the effect of reducing the residual amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

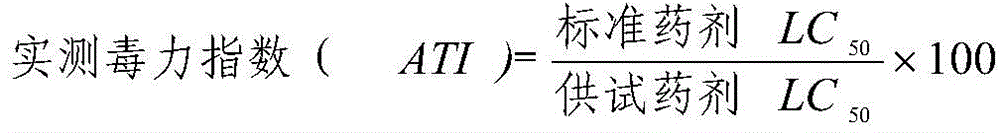

Method used

Image

Examples

Embodiment 1

[0031] Example 1: 12.1% HNPC-A8008·chlorpyrifos suspension.

[0032] When the present invention is processed into a suspending agent, the weight percentage of each component is: HNPC-A800 80.1%; chlorpyrifos 12%; emulsifier: BY-1404%, nonylphenol polyoxyethylene ether 6%; solvent: cyclo Hexanone 5%, methanol 6%; wetting agent: sodium butylnaphthalene sulfonate: 3%; dispersant agent calcium alkylbenzene sulfonate: 3%; antifreeze agent: propylene glycol 1%; thickener: xanthan gum 0.1% ; Defoamer silicone: 0.1%; Deionized water added to 100%. The specific production steps of the suspension are: first mix the above-mentioned components except the active ingredients, and mix them evenly through high-speed shearing, then add the active ingredients HNPC-A8008 and chlorpyrifos, and grind in a ball mill for 2 to 3 hours , so that the particle size of all the particles is below 5 μm, that is, the suspension preparation of the composition of the present invention is made.

Embodiment 2

[0033] Example 2: 12.1% HNPC-A8008 Chlorpyrifos emulsion in water

[0034] When the present invention is processed into an aqueous emulsion, the weight percentage of each component is: HNPC-A800812%; chlorpyrifos 0.1%; emulsifier agricultural milk 500% # 8%, nonylphenol ethoxylate 5%; solvent: cyclohexanone 6%, methanol 7%; stabilizer: sodium citrate 1%; antifreeze: propylene glycol 1%; thickener: xanthan gum 0.1 %; deionized water added to 100%. The specific production steps of the water emulsion are: first, add HNPC-A8008, chlorpyrifos, solvent and emulsifier together to dissolve into a uniform oil phase; then mix some deionized water, stabilizer and other additives together to form a uniform water phase; then add the oil phase to the water phase while stirring at high speed in the reactor, add water slowly until reaching the phase inversion point, turn on the shearing machine for high-speed shearing, and add the remaining deionized water, shear About half an hour, form th...

Embodiment 3

[0035] Example 3: 20% HNPC-A8008 Chlorpyrifos microemulsion

[0036]When the present invention is processed into a microemulsion, the weight percentage of each component is: HNPC-A8008 10%; chlorpyrifos 10%; solvent: 5% cyclohexanone, methanol 8%; emulsifier: calcium alkylbenzenesulfonate 5% , benzyl dimethylphenol polyoxyethyl ether 7%; antifreeze: propylene glycol 1%; stabilizer: sodium citrate 1%; deionized water added to 100%. The specific production steps of the microemulsion are: first completely dissolve HNPC-A8008 and chlorpyrifos in a solvent, then add emulsifier, antifreeze and other auxiliary agents, stir and mix evenly in a stirring mixing tank, and then the composition of the present invention can be produced microemulsion formulations.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com