Preparation method and application SiO2/GO surface metal ion imprinted polymer

An ion imprinting, surface metal technology, applied in the directions of alkali metal compounds, alkali metal oxides/hydroxides, chemical instruments and methods, etc. It has problems such as real-time sensitivity, and achieves excellent specific recognition performance, good mechanical properties and thermal stability, and avoids incomplete elution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

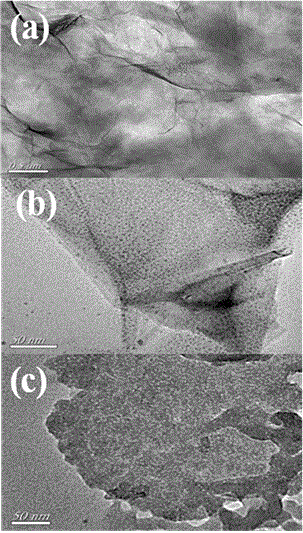

[0048] (1) Take 5 mL of 2 g / L graphene oxide aqueous solution and Erlenmeyer flask, then add 40 mL of absolute ethanol; and weigh 0.2 g of polyvinylpyrrolidone into the above mixed solution, and stir magnetically at room temperature for 30 min. Then, 2 mL of concentrated ammonia water and 0.5 mL of tetraethylorthosilicate were added to the above mixed solution, and the mixture was ultrasonically reacted for 30 min. Finally, it was placed in a water bath at 30 °C for 12 h. After the reaction, wash with deionized water to neutrality, and dry in vacuum at 50°C to obtain the silica / graphene oxide composite material (SiO 2 / GO).

[0049] (2) 50 mg SiO obtained in step (1) 2 / GO was added to 25 mL of ethanol solution, and dispersed evenly by ultrasonication. Then, 2.5 mL of MPS was added to the above mixed solution, placed in a water bath at 30 °C, and stirred magnetically for 8 h. After the reaction, the product was washed with ethanol and deionized water for 5 times to elute un...

Embodiment 2

[0056] (1) Take 5 mL of 2 g / L graphene oxide aqueous solution and Erlenmeyer flask, then add 40 mL of absolute ethanol; and weigh 0.5 g of polyvinylpyrrolidone into the above mixed solution, and magnetically stir at room temperature for 60 min. Then, 2 mL concentrated ammonia water and 0.5 mL tetraethyl orthosilicate were added to the above mixed solution, and the reaction was ultrasonicated for 60 min. Finally, react in a water bath at 40 °C for 24 h. After the reaction, wash with deionized water to neutrality, and dry in vacuum at 50°C to obtain the silica / graphene oxide composite material (SiO 2 / GO).

[0057] (2) 100 mg SiO obtained in step (1) 2 / GO was added to 50 mL of ethanol solution and dispersed evenly by ultrasonication. Then, 5 mL of MPS was added to the above mixed solution, and placed in a 40 °C water bath, and magnetically stirred for 12 h. After the reaction, the product was washed with ethanol and deionized water for 5 times to elute unreacted MPS. , drie...

Embodiment 3

[0063] (1) Take 5 mL of 2 g / L graphene oxide aqueous solution and Erlenmeyer flask, then add 40 mL of absolute ethanol; and weigh 1 g of polyvinylpyrrolidone into the above mixed solution, and magnetically stir at room temperature for 90 min. Then, 2 mL of concentrated ammonia water and 0.5 mL of tetraethylorthosilicate were added to the above mixed solution, and the mixture was ultrasonically reacted for 90 min. Finally, react in a 50 °C water bath for 36 h. After the reaction, wash with deionized water to neutrality, and dry in vacuum at 50°C to obtain the silica / graphene oxide composite material (SiO 2 / GO).

[0064] (2) 200 mg SiO obtained in step (1) 2 / GO was added to 100 mL of ethanol solution, and dispersed evenly by ultrasonication. Then, 10 mL of MPS was added to the above mixed solution, placed in a 50 °C water bath, and magnetically stirred for 24 h. After the reaction, the product was washed with ethanol and deionized water for 5 times to elute unreacted MPS. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com