Reactive organosilicon waterproofing agent as well as preparation method and application thereof

A reactive, organosilicon technology, applied in the fields of organosilicon chemistry and material science, to achieve the effects of simple and easy application method, stable storage, and simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

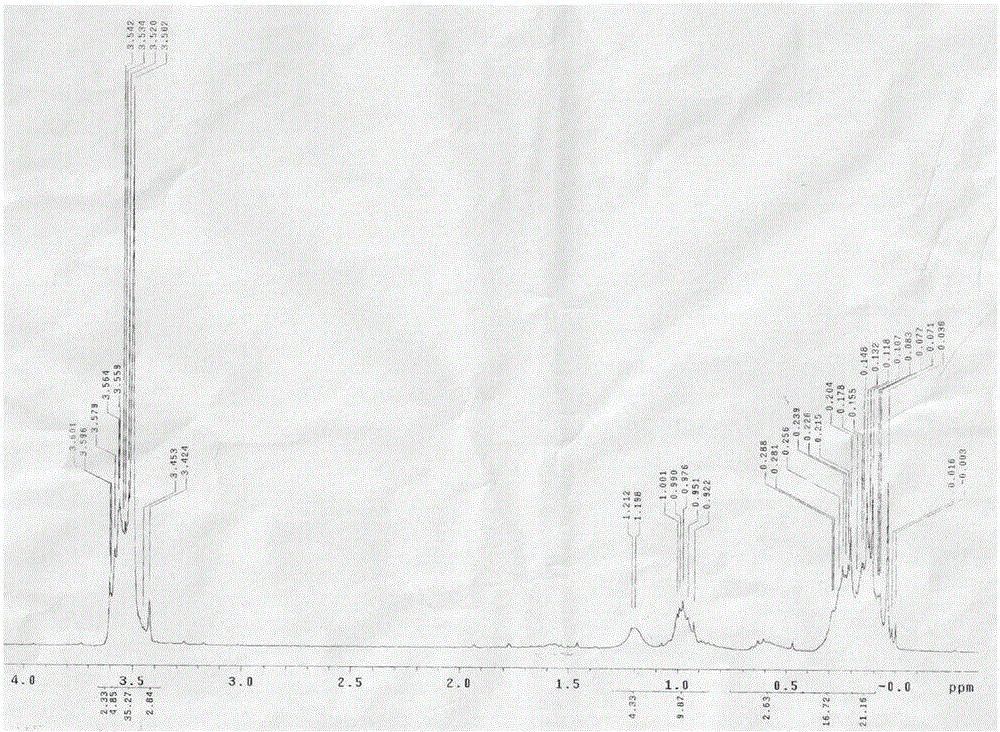

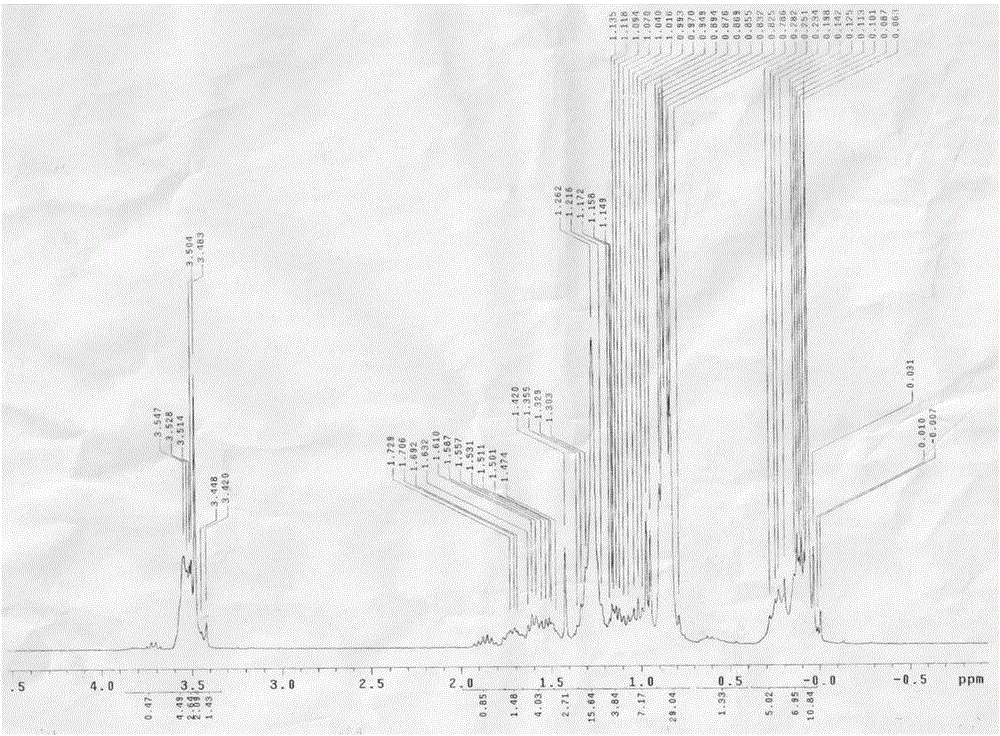

Method used

Image

Examples

Embodiment 1

[0039] Prepare HSi(OR) by 296 grams of silanol direct method 3 Add the obtained by-products into the three-necked flask, raise the temperature to 50°C under magnetic stirring, and add 37.5 grams of deionized water dropwise according to the calculation of the by-product mixture under stirring. 325 grams of organochlorosilane, the temperature was kept at 50-70°C during the dropping process and the HCl produced by the reaction was absorbed with lye; Hours; then lower the temperature to below 40°C, add neutralizing agent sodium bicarbonate until the reaction system is neutral, filter out the solid with filter paper, then heat the filtrate to 100°C, remove low boiling substances under reduced pressure, and obtain the reaction type MDTQ Silicone resin (462 g), viscosity 23 cSt, yield 74.4%.

Embodiment 2

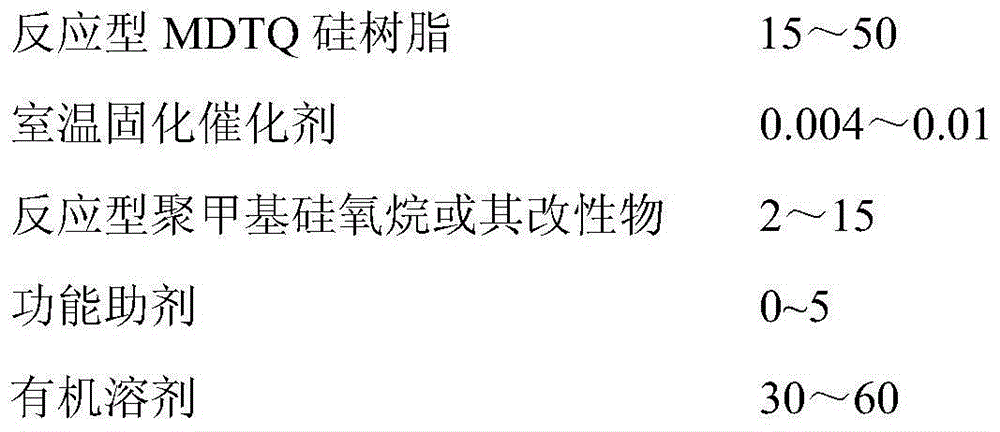

[0041] Weigh 297 grams of reactive MDTQ silicone resin, place it in a dry reactor with stirring function, add 453 grams of 60-90 petroleum ether under stirring conditions, and then add 16 grams of reactive polymethylsiloxane to modify sex 0.04 grams of dibutyltin diacetate and 30 grams of silane coupling agent, stirred evenly, and then packed in a sealed container under the protection of dry nitrogen. The waterproof agent has excellent waterproof performance, fast curing speed and good permeability.

Embodiment 3

[0043] Take by weighing 320 grams of reactive MDTQ silicone resin, place it in a dry reactor with stirring function, add 430 grams of 100 # Solvent oil, then add 21 grams of reactive polymethylsiloxane modified product 0.03 grams of stannous salt and 30 grams of high-temperature additives were stirred for 15 minutes, and finally 0.05 grams of dibutyltin dilaurate was added and stirred evenly, and then packed in a sealed container under the protection of dry nitrogen. The waterproof agent has excellent waterproof performance and permeability, and the curing speed is moderate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com