High temperature pressure sensor and process method thereof

A technology of pressure sensor and processing method, which is applied in the direction of fluid pressure measurement by changing ohmic resistance, can solve the problems of difficult long-term operation of silicon-based sensors, and achieve the effects of eliminating leakage current, improving working temperature, and good thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the above objects, features and advantages of the present invention more obvious and understandable, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

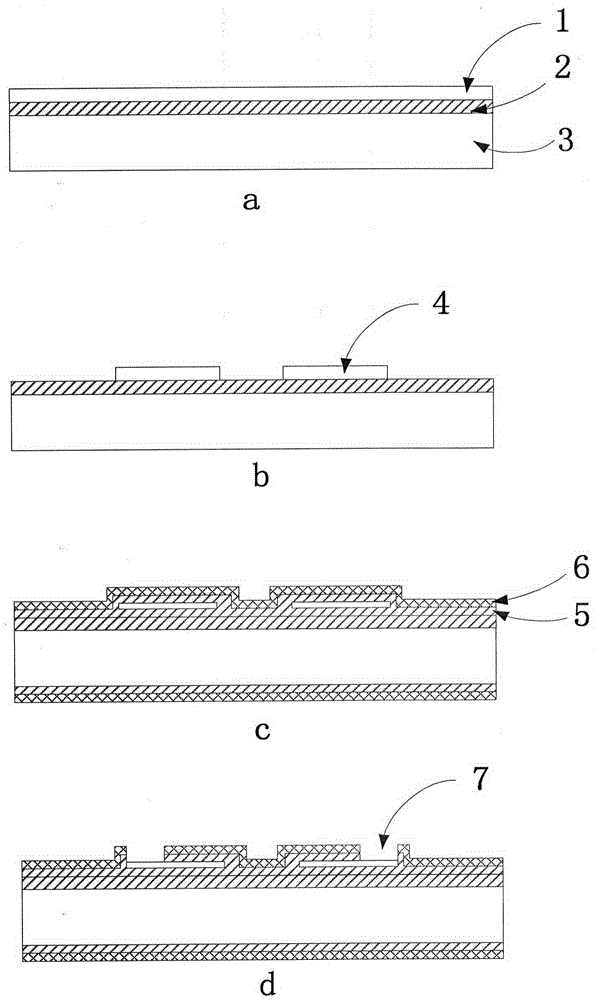

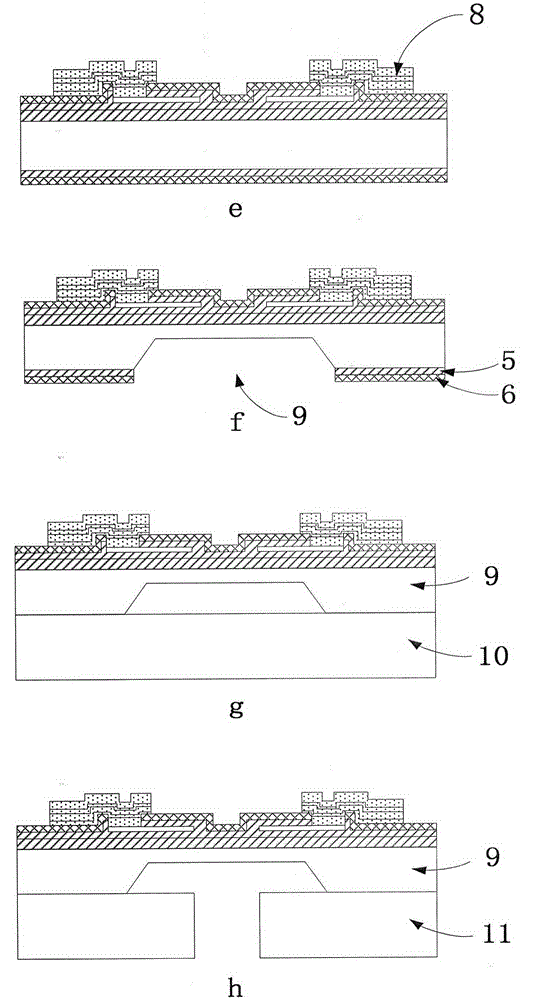

[0018] figure 1 (a)~ figure 1 (h) is a schematic diagram of the main processing technology of the high-temperature pressure sensor processed by the present invention;

[0019] figure 1 (a) shows the double-sided polished SOI single-crystal silicon wafer used for processing the high-temperature pressure sensor of the present invention, the device layer 1 is N (100) single-crystal silicon, and the thickness of the buried oxide layer 2 is The substrate layer 3 has a thickness of 400um.

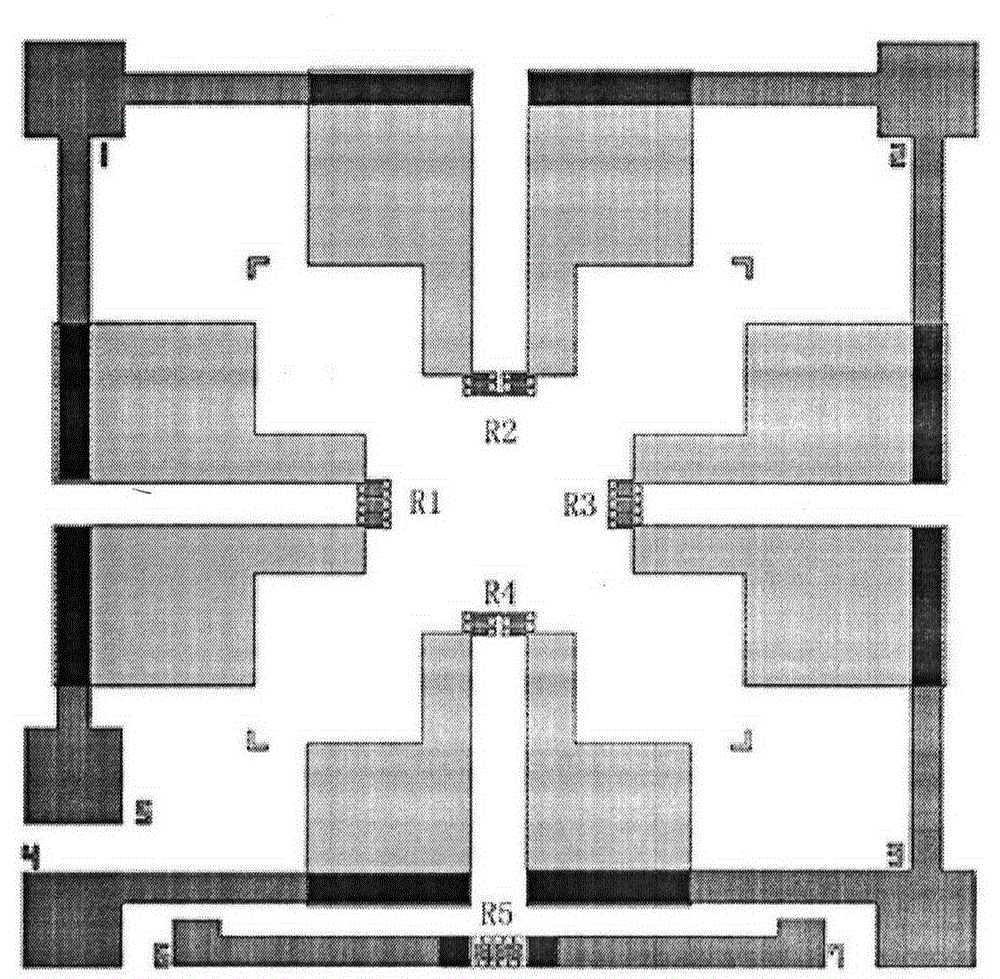

[0020] Such as figure 1 As shown in (b), perform boron ion implantation and annealing, and etch the device layer of the substrate to form the bridge arm resistance 4 of the Wheatstone bridge. Since increasing the doping concentratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com