Manufacturing method of gallium-nitride-based high-electron-mobility transistor of flip-chip structure

A high electron mobility, gallium nitride-based technology, applied in the field of fabrication of gallium nitride-based high electron mobility transistors, can solve the problems of rough material interface, reduce the quality of GaN crystals, etc., achieve good heat dissipation performance, and realize device integration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

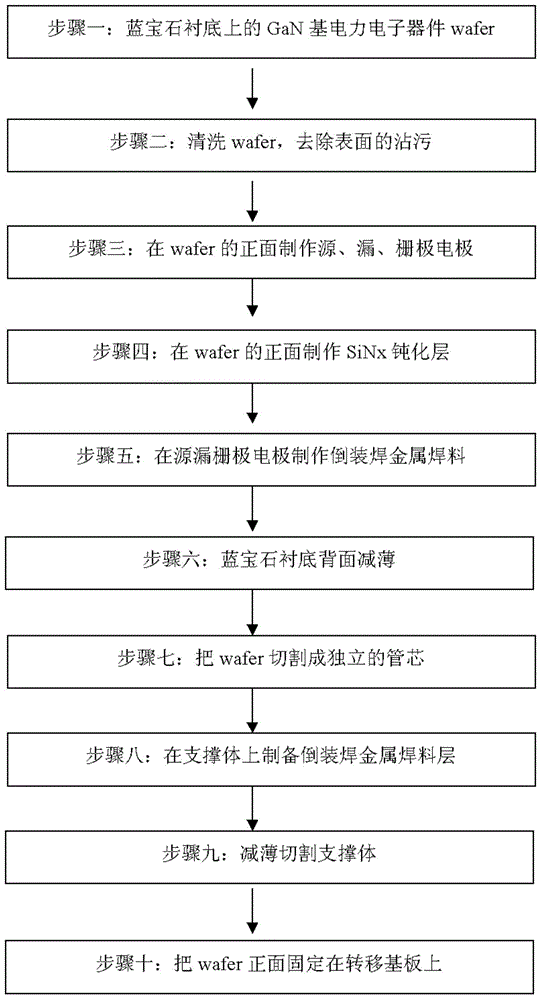

[0022] See figure 1 For reference figure 2 As shown, the present invention provides a method for manufacturing a gallium nitride-based high electron mobility transistor with a flip-chip structure, which includes the following steps:

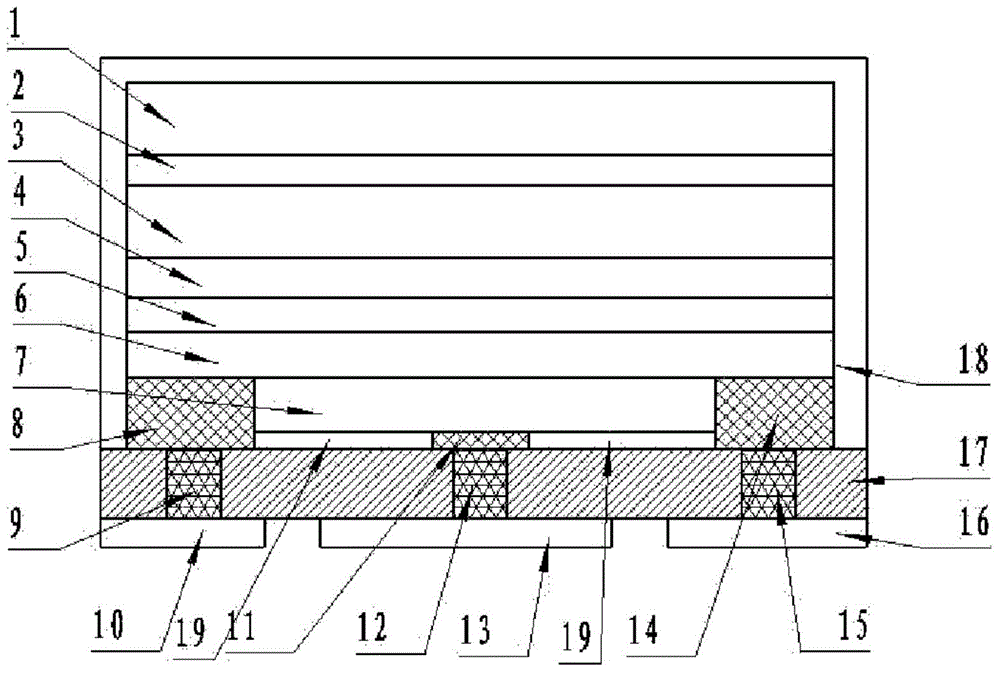

[0023] Step 1: On the sapphire substrate 1, a low-temperature nucleation layer 2, a gallium nitride high-resistance layer 3, a high-mobility gallium nitride layer 4, an aluminum nitride insertion layer 5, an aluminum gallium nitride barrier layer 6 and The gallium nitride cap layer 7 forms an epitaxial wafer. The material of the low-temperature nucleation layer 2 is gallium nitride, aluminum nitride or aluminum gallium nitride, and the thickness is 20-100 nm. The gallium nitride high resistance layer 3 The thickness of the high-mobility gallium nitride layer 4 is 500-5000nm, the thickness of the high-mobility gallium nitride layer 4 is 10-300nm, the thickness of the aluminum nitride insertion layer 5 is 0-5nm, and the aluminum gallium nitride barri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com