Weeding composition containing pyroxsulam, chodinafop-propargyl and fluroxypyr

A technology of fluroxypyr and fluroxypyr, which is applied in the field of pesticides, can solve the problems of affecting the speed of drug efficacy, plant death, and slow drug effect, so as to achieve less resistance to pesticides and expand the weeding spectrum , quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

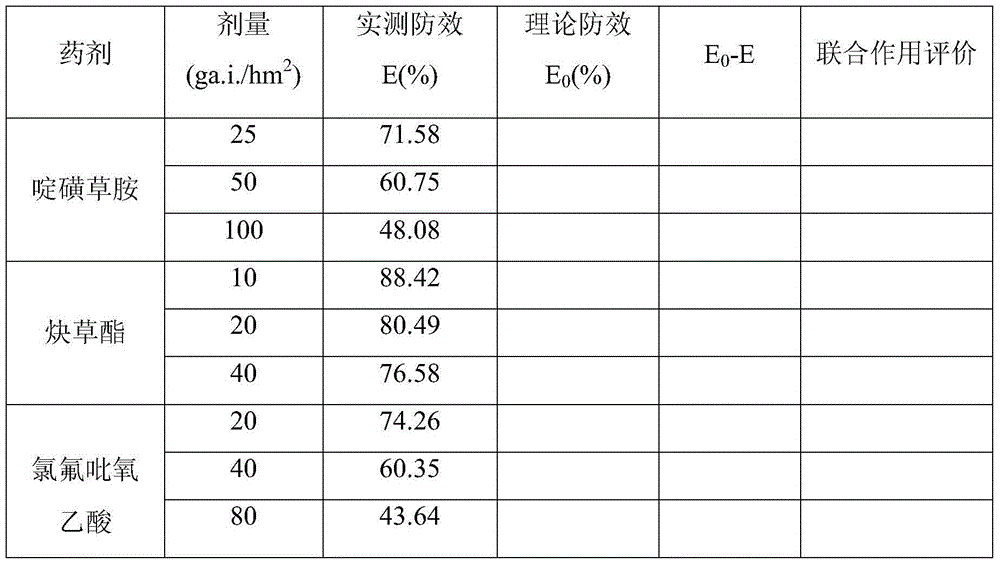

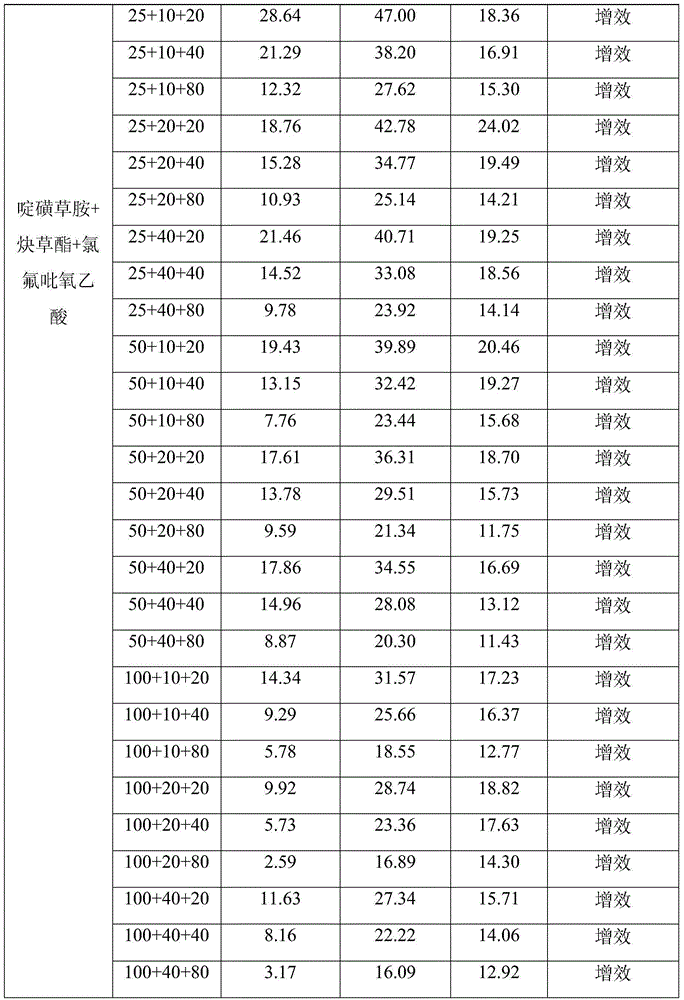

Method used

Image

Examples

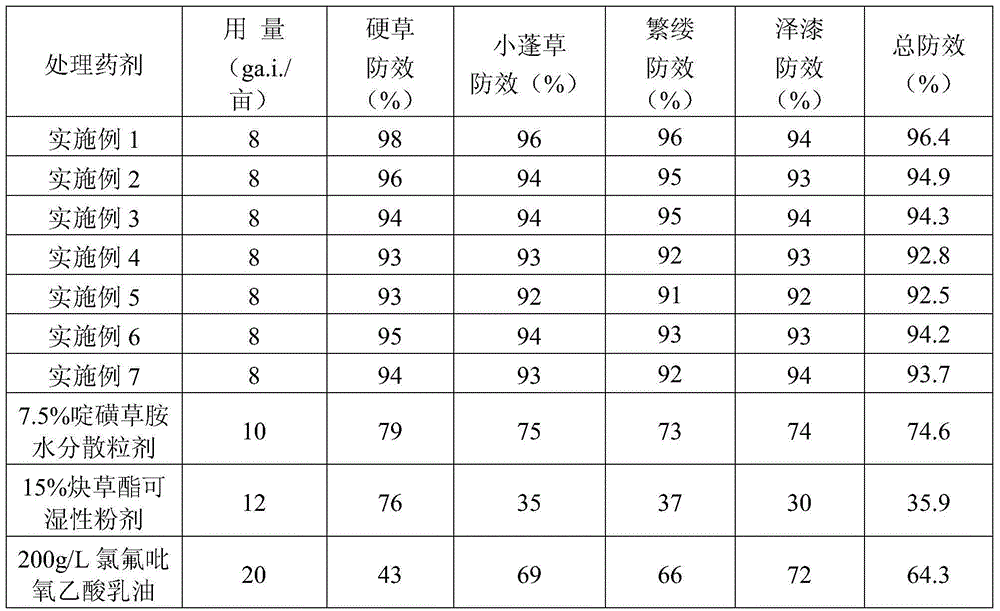

Embodiment 1

[0030] Example 1 32.5% acesulfame-clodinafop-propargyl-fluroxypyr wettable powder

[0031] 12.5% of acesulfame, 10% of clodinafop-propargyl, 10% of fluroxypyr, 2% of sodium lignosulfonate, 1% of sodium dodecylbenzenesulfonate, and 100% of kaolin were added to obtain 32.5 % acesulfame-clodinafop-propargyl-fluroxypyr wettable powder.

[0032] Mix acesulfame, clodinafop-propargyl, fluroxyfen, dispersant (sodium lignosulfonate), wetting agent (sodium dodecylbenzenesulfonate), filler (kaolin), and mix in a mixing tank Evenly, it can be made into wettable powder after pulverized by jet mill and then mixed evenly.

Embodiment 2

[0033] Example 2 64% acesulfame-clodinafop-propargyl-fluroxypyr water-dispersible granules

[0034]Acesulfame 40%, clodinafop-propargyl 8%, fluroxyfen 16%, fatty alcohol polyoxyethylene ether 5%, saponin powder 4%, ammonium sulfate 2%, diatomaceous earth added to 100%, A 64% acesulfame-clodinafop-propargyl-fluroxyfen water-dispersible granule was prepared.

[0035] Acesulfame, clodinafop-propargyl, fluroxyfen, dispersant (fatty alcohol polyoxyethylene ether), wetting agent (saponica powder), disintegrant (ammonium sulfate), filler (diatomaceous earth ) and so on to obtain the required particle size through jet crushing to obtain the granulation material. Quantitatively send the material into the fluidized bed granulation dryer for granulation and drying to obtain water-dispersible granules.

Embodiment 3

[0036] Example 3 60% acesulfame-clodinafop-propargyl-fluroxypyr suspension concentrate

[0037] Acesulfame 30%, clodinafop-propargyl 6%, fluroxypyr 24%, sodium lignosulfonate 5%, aluminum magnesium silicate 1%, C 10~20 Saturated fatty acids 0.3%, polyethylene glycol 2.5%, water added to 100%, prepared 60% acesulfame-clodinafop-propargyl-fluroxyacetic acid suspension concentrate.

[0038] Dispersant (sodium lignosulfonate), thickener (magnesium aluminum silicate), defoamer (C 10~20 Saturated fatty acids), antifreeze agent (polyethylene glycol) after high-speed shearing and mixing evenly, add pyresullam, clodinafop-propargyl, and fluroxyfen, and ball mill in a ball mill for 2 to 3 hours to make the particle size completely Below 5 μm, a suspension product is produced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com