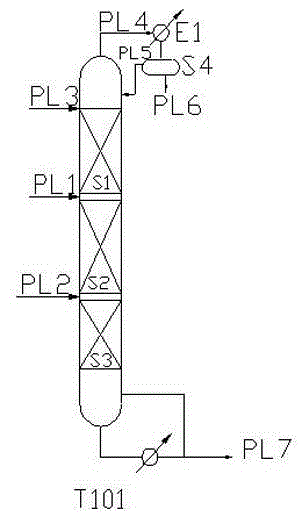

Solid super acid for catalytically synthesizing PMA (2-acetoxy-1-methoxypropane), and catalytic rectification technique and apparatus thereof

A technology of solid superacid and catalytic distillation, which is applied in the field of solid superacid for catalyzing the synthesis of PMA and its catalytic distillation process and equipment. Application and other issues, to achieve the effect of large-scale continuous production, improve the performance of repeated use, and improve the conversion rate of esterification reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A kind of solid superacid of catalytic synthesis PMA, its preparation method comprises the steps:

[0036] 1) Preparation of solid superacid TiO 2 / SO 4 2- Powder: Accurately weigh nano-sized TiO 2 Powder 20g in a watch glass, with 20g 2mol / L of H 2 SO 4 The solution was impregnated, and the two were fully stirred with a glass rod until it was a paste; then it was put into a vacuum drying oven at 0.1MPa and 120°C for 3 hours in vacuum; then the dried powder was transferred to a crucible and placed in a horse Roasting in the furnace, the calcination temperature is 500 ℃, and the calcination time is 2h, to obtain the solid super acid TiO 2 / SO 4 2- powder;

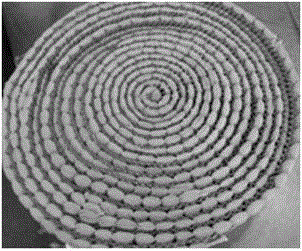

[0037] 2) Preparation of shaped solid superacid: the solid superacid TiO obtained in step 1) 2 / SO 4 2- Mix the powder with the binder pseudo-boehmite, the reinforcing agent glass fiber, and the pore-forming agent activated carbon evenly, then add the lubricant glycerin and deionized water, and knead for 30...

Embodiment 2

[0043] A kind of solid superacid of catalytic synthesis PMA, its preparation method comprises the steps:

[0044] 1) Preparation of solid superacid TiO 2 / SO 4 2- Powder: Accurately weigh nano-sized TiO 2 Powder 20g in a watch glass, with 30g 1mol / L of H 2 SO 4 The solution was impregnated, and the two were fully stirred with a glass rod until it was a paste; then it was placed in a vacuum drying oven at 0.1MPa and 90°C for 3 hours in vacuum; then the dried powder was transferred to a crucible and placed in a horse Roasting in a furnace, the calcination temperature is 350°C, and the calcination time is 5h, to obtain the solid super acid TiO 2 / SO 4 2- powder;

[0045] 2) Preparation of shaped solid superacid: the solid superacid TiO obtained in step 1) 2 / SO 4 2- The powder is evenly mixed with the binder fennel powder, the reinforcing agent glass fiber, and the pore-forming agent activated carbon, and then the lubricant glycerin and deionized water are added, and k...

Embodiment 3

[0051] A kind of solid superacid of catalytic synthesis PMA, its preparation method comprises the steps:

[0052] 1) Preparation of solid superacid TiO 2 / SO 4 2- Catalyst powder: accurately weigh nano-sized TiO 2 Powder 20g in a watch glass, with 50g 0.5mol / L of H 2 SO 4 The solution was impregnated, and the two were fully stirred with a glass rod until it was a paste; then it was placed in a vacuum drying oven at 0.1MPa and 110°C for 3 hours in vacuum; then the dried powder was transferred to a crucible and placed in a horse Roasting in a furnace, the calcination temperature is 400°C, and the calcination time is 3h, to obtain solid superacid TiO 2 / SO 4 2- catalyst powder;

[0053] 2) Preparation of shaped solid superacid: the solid superacid TiO obtained in step 1) 2 / SO 4 2- Catalyst powder, binder alumina, reinforcing agent glass fiber, and pore-forming agent activated carbon are evenly mixed, then lubricant glycerin and deionized water are added, and kneading ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com