Honeycomb ceramic carrier and preparation method thereof

A honeycomb ceramic carrier and ceramic technology, which is applied in catalyst carriers, chemical instruments and methods, catalyst activation/preparation, etc., can solve the problems of peeling, unfavorable industrialization, easy cracking of coatings, etc. , the effect of high firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

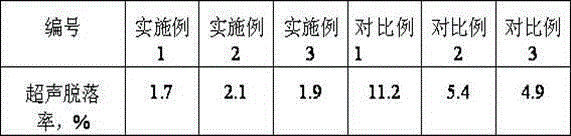

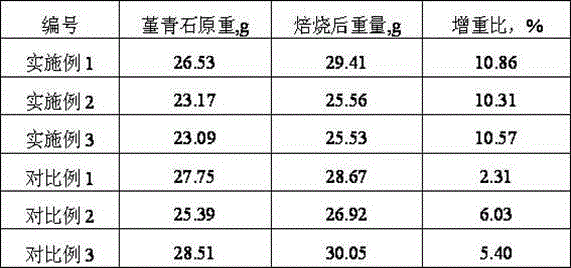

Examples

Embodiment 1

[0032] Cordierite pretreatment: completely immerse cordierite honeycomb ceramics in 5wt% nitric acid solution for 1 hour, rinse with deionized water for 3 times after taking it out, put it in an oven at 120°C, and dry it for 10 hours to obtain Surface activated cordierite honeycomb ceramic support.

[0033] Aluminum sol preparation: 20 grams of pseudoboehmite was added to 150 mL of deionized water, and 7 grams of concentrated nitric acid was added dropwise while stirring. After stirring for a certain period of time, heat to 80°C, add nitric acid dropwise until completely peptized, control the pH value of the solution at 2~5, and age for 24 hours to obtain a transparent aluminum sol with a content of 8% based on alumina.

[0034] Composite coating slurry preparation: add 178ml of nitric acid solution (0.1mol / In L), after stirring evenly, add 52 grams of aluminum sol to it, use a high-shear dispersing emulsifier (FLUKO FA25 10000rpm) to shear and disperse for 10 minutes, and t...

Embodiment 2

[0038] Cordierite pretreatment: with embodiment 1.

[0039] Aluminum sol is commercially available (solid content is 15%, pH is 3-4).

[0040] Composite coating slurry preparation: Add 54 grams of nano-titanium dioxide (50-100nm), 32 grams of fumed silica (10-80nm), and 17.2 grams of nano-cerium oxide into 280ml of carbonic acid solution (0.2mol / L), and stir evenly Finally, add 43 grams of aluminum sol to it, stir and mix for 90 minutes until uniform, add 4.3 grams of alkylphenol polyoxyethylene ether (molecular formula is RC 6 h 4 O(CH 2 CH 2 O) n H, where R is C 9 ~C 12 , n is 9~12), and then stir and mix for 30 minutes to obtain a uniform coating slurry.

[0041] Coating loading: immerse the pretreated cordierite honeycomb ceramic carrier in the above aluminum sol for 10 minutes, take it out, blow off the residual liquid, dry at 120°C for 8 hours, and bake at 550°C for 5 hours.

[0042] Composite coating loading: After immersing the alumina-coated carrier in the abo...

Embodiment 3

[0044] Cordierite pretreatment: with embodiment 1.

[0045] Aluminum sol preparation: same as embodiment 1.

[0046] Composite coating slurry preparation: Add 25 grams of nano-titanium dioxide (100-150nm), 5 grams of fumed silica (10-80nm), and 9.2 grams of nano-zirconia into 210ml of carbonic acid solution (0.3mol / L), and stir evenly Finally, 45 grams of aluminum sol was added thereto, and 6.1 grams of secondary octanol polyoxyethylene ether (molecular formula C 8 h 17 (CH 2 CH 2 O) n H, wherein n is 1 ~ 6), and then shear and disperse for 5 minutes to obtain a coating slurry.

[0047] Alumina coating loading: immerse the pretreated cordierite honeycomb ceramic carrier in the above-prepared aluminum sol for 8 minutes, take it out, blow off the residual liquid, dry at 110°C for 10 hours, and bake at 500°C for 5 hours.

[0048] Composite coating loading: After immersing the alumina-coated carrier in the above-mentioned additive solution for 8 minutes, take it out, blow of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com