Ethylene oligomerization method

A technology of ethylene oligomerization and ethylene, which is applied in the field of olefin polymerization, can solve problems such as unreachable, harsh environmental requirements, and high unit price, and achieve high oligomerization reactivity, simplified production process, and high selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

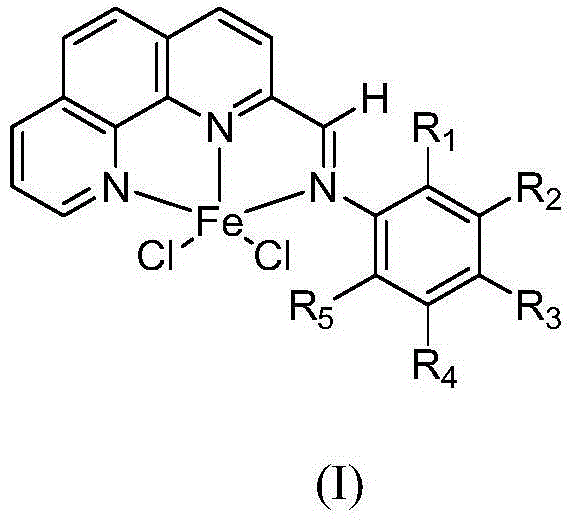

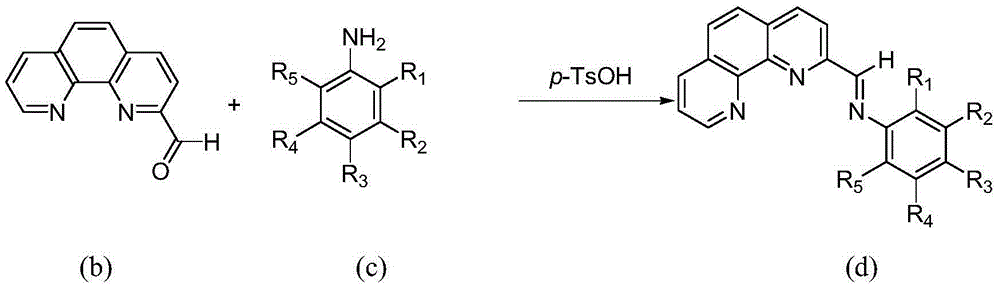

[0039] 1. Catalyst synthesis of 2-formyl-1,10-phenanthroline chloride 2,6-diethylanilinate iron (II) complex

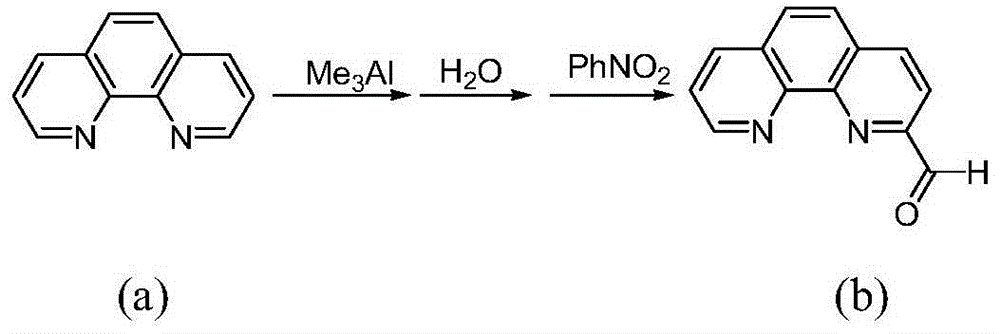

[0040] a. Synthesis of 2-formyl-1,10-phenanthroline (see the following reaction scheme)

[0041]

[0042] Put 5.1 g (28.3 mmol) of 1,10-phenanthroline into a 250 ml three-necked flask, and dissolve it with 100 ml of toluene under nitrogen protection and magnetic stirring. Slowly add 4ml of trimethylaluminum (d=0.75g / ml, 41.7mmol) dropwise to the three-necked flask under stirring at -60°C, the dropwise addition is completed in about 15 minutes, continue stirring at this temperature for 18h, and then raise the temperature To about 30 ℃, continue to stir for 10h. Then the reaction mixture was cooled to about -30°C, 50ml of distilled water was slowly added thereto, and then heated to 30°C and stirred for 10h. Then separate the liquids, take out the organic phase, and extract the inorganic phase three times with dichloromethane, each time the consumption of dichlorome...

Embodiment 2

[0057] The method of Example 1 was adopted to carry out the ethylene oligomerization reaction, the difference being that the weight content of water was 20 ppm based on the weight of the solvent 1-hexene, and the analysis results were shown in Table 1.

Embodiment 3

[0059] The method of Example 1 was adopted to carry out the ethylene oligomerization reaction, the difference being that the weight content of water was 50 ppm based on the weight of the solvent 1-hexene, and the analysis results were shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com