Novel method for catalytically synthesizing benzyl salicylate via solid-liquid phase transfer

A technology of benzyl salicylate and solid-liquid phase, applied in chemical instruments and methods, preparation of organic compounds, catalytic reactions, etc., can solve the problems of high cost and high cost of benzyl alcohol, and achieve low cost, high reaction conversion rate and The effect of high selectivity and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

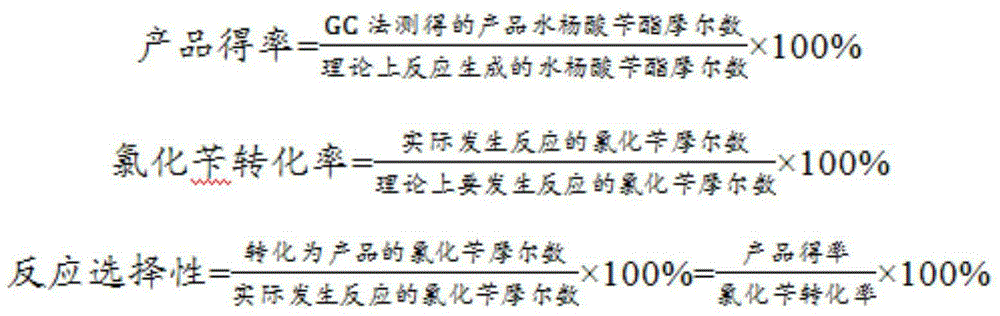

Embodiment 1

[0022] A new method for the synthesis of benzyl salicylate by solid-liquid phase transfer catalysis: Take 84.05g (525mmol) of sodium salicylate, 63.3g (500mmol) of benzyl chloride, crown ether (25mmol) and sodium iodide (3mmol), and add three mouthfuls In a bottom flask, react at 140℃ for 3h. After the reaction is complete, add water to separate the reaction liquid, separate the organic layer, wash the organic layer with distilled water, and then use NaHCO with a concentration of 5% by mass. 3 Wash twice with aqueous solution and then twice with distilled water. After dehydration and vacuum distillation, the fractions at 164-165°C / 730Pa are collected to obtain the benzyl salicylate product. The product is a colorless and transparent liquid with white needle-like crystals at low temperatures. Detected by gas chromatography, the product purity is 99.37%, and the product yield is 92.72%. The conversion rate of benzyl chloride was 98.62%, and the reaction selectivity was 94.02%.

Embodiment 2

[0024] A new method for the synthesis of benzyl salicylate by solid-liquid phase transfer catalysis: Take 96.1g (600mmol) of sodium salicylate, 63.3g (500mmol) of benzyl chloride, PEG-600 (25mmol) and potassium iodide (3mmol), add three round bottoms In the flask, react for 4 hours at a temperature of 145℃. After the reaction is completed, add water to separate the reaction liquid, separate the organic layer, wash the organic layer with distilled water, and then use NaHCO with a concentration of 5% by mass. 3 Wash twice with aqueous solution and then twice with distilled water. After dehydration and vacuum distillation, the fractions at 164-165°C / 730Pa are collected to obtain the benzyl salicylate product. The product is a colorless and transparent liquid with white needle-like crystals at low temperatures. Detected by gas chromatography, the product purity is 99.78%, and the product yield is 95.27%. The conversion rate of benzyl chloride was 98.91%, and the reaction selectivit...

Embodiment 3

[0026] A new method for the synthesis of benzyl salicylate by solid-liquid phase transfer catalysis: 315.05g (1.97mol) of sodium salicylate, 237.98g (1.88mmol) of benzyl chloride, PEG-2000 (94mmol) and potassium chloride (11.27mmol) , Put it into a three-necked round-bottom flask, react for 4h at a temperature of 145℃, after the reaction is complete, add water to separate the reaction liquid, separate the organic layer, wash the organic layer with distilled water, and then use 5% by mass NaHCO 3 Wash twice with aqueous solution and then twice with distilled water. After dehydration and vacuum distillation, the fractions at 164-165°C / 730Pa are collected to obtain the benzyl salicylate product. The product is a colorless and transparent liquid with white needle-like crystals at low temperatures. Detected by gas chromatography, the product purity is 99.40%, and the product yield is 94.13%. The conversion rate of benzyl chloride was 98.82%, and the reaction selectivity was 95.25%....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com