Fluorescent complex containing carboxylic acid type high polymer and rare earth, preparation method of fluorescent complex, fluorescent chemical carbon powder and preparation method of fluorescent chemical carbon powder

A carboxylic acid polymer, rare earth fluorescence technology, applied in the field of toner manufacturing, can solve the problems of uneven dispersion of fluorescent substances, poor fixing of fluorescent chemical toners, high requirements for dispersion of fluorescent powders, etc., and can solve the problems of uneven distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

[0043] (1) Preparation of carboxylic acid polymer rare earth fluorescent polymer A1:

[0044] 35.31g acrylic acid (0.49mol), 42.3g butyl acrylate (0.33mol) and 16g methyl methacrylate (0.16mol) were dissolved in 93.61g ethyl acetate, ethanol mixed solvent (ethyl acetate and ethanol mass ratio is 3:1), placed in a flask, add 1.04g benzoyl peroxide, 3.74g dodecyl mercaptan, heat up to 75 degrees Celsius, after reacting for 3h, cool to obtain a polymer resin solution; resin molecular weight by VARIAN PL- According to GPC50 measurement, its molecular weight is 9634g / mol.

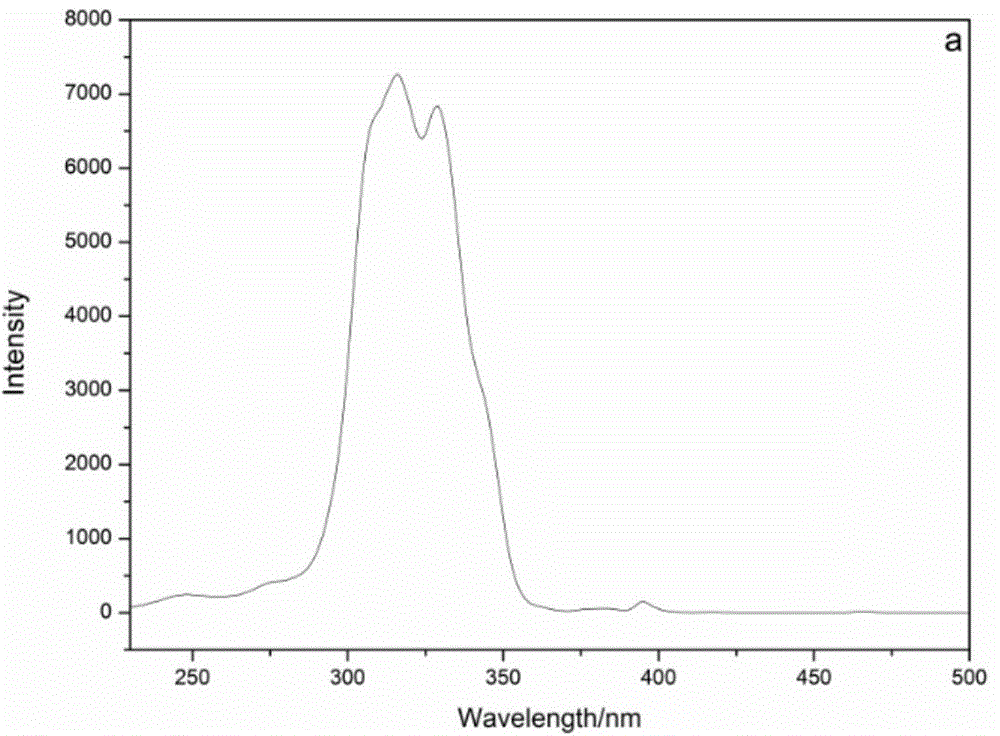

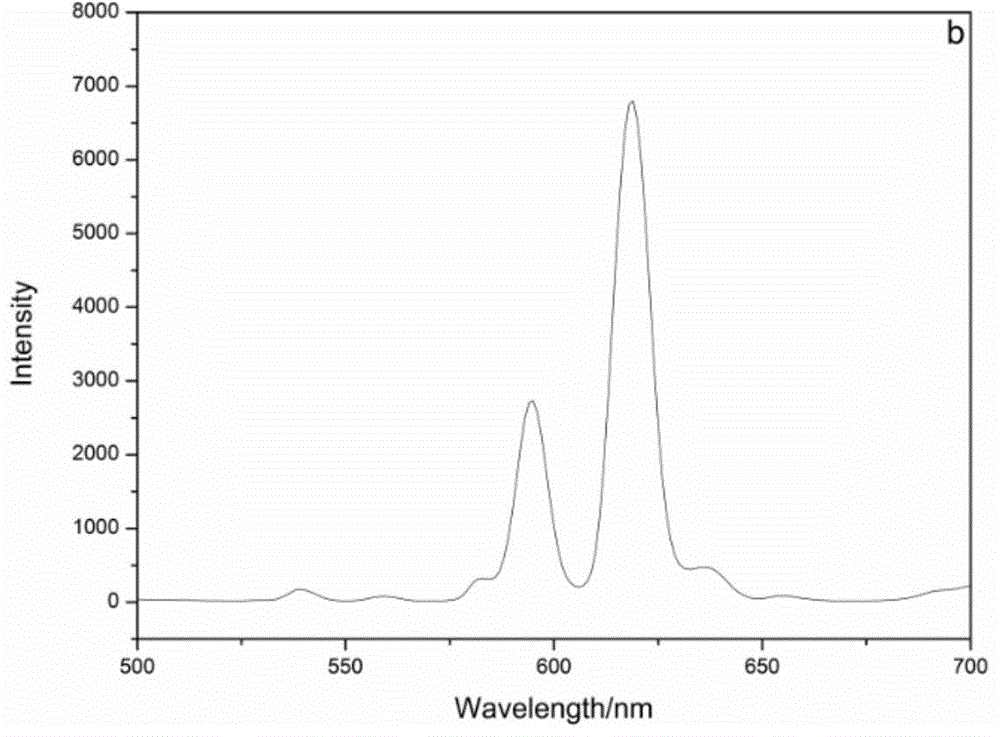

[0045] A tetrahydrofuran solution containing 41.4 g of europium nitrate (0.125 mol), 24.78 g of o-phenanthroline (0.125 mol), and 4.1 g of yttrium nitrate were added to the polymer resin solution. Maintain the reaction temperature at 40°C and the reaction time for 10 hours to obtain a sol solution; raise the temperature of the sol solution to 65°C, remove the solvent by vacuuming, wash the obtained solid with a...

preparation example 1

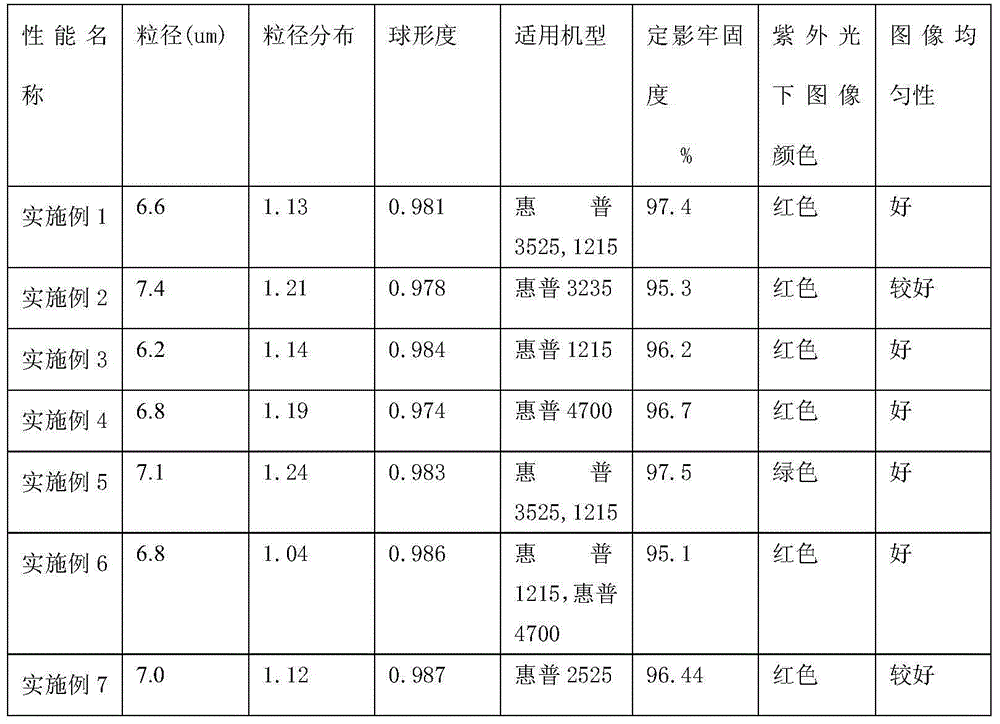

[0076] Add 100g of emulsion A1 into the reaction kettle, adjust the stirring speed to 500rpm, then gradually add emulsion B1 into the reaction kettle within 20 minutes under stirring, start to heat up after stirring for 30 minutes, and raise the temperature of the system to 65 ℃, then reduce the stirring speed of the system to 200rpm, and then start to detect the change of the particle size of the system, when the particle size of the aggregated particles increases to 7 μm, add nonionic surfactant X-405 (Dow Chemical ), then increase the stirring speed to 350rpm, and then raise the temperature to 95°C for spheroidization. When the sphericity of the particles reaches above 0.97 (measured by FPIA-3000), cool them down, filter them with a centrifuge, wash them with water, and heat them down. Press dry. Add external additives to the dried particles to obtain carbon powder. The obtained toner is referred to as Toner (T-1).

preparation example 2

[0078] In the carbon powder preparation example 1, except that the emulsion A1 was replaced with the emulsion A2. The obtained carbon powder is called carbon powder (T-2);

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com