Low-free-TDI (toluene diisocyanate) polyurethane polyester curing agent and preparation method thereof

A polyurethane, low-free technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of expensive equipment, large solvent consumption, complicated operation, etc., achieve good film-forming performance and wide application, reduce pollution Harmful and economical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

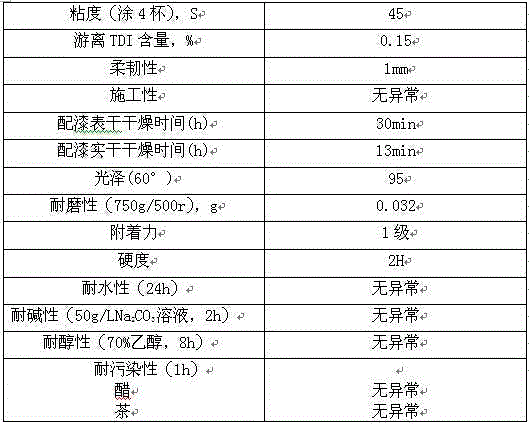

Embodiment 1

[0017] A kind of low free TDI polyurethane polyester resin curing agent described in the present embodiment, it is made of containing weight ratio 14.53g polyester resin, 0.98g trimethylolpropane, 3.66g neopentyl glycol, 0.05g phosphoric acid, 0.26gK54, 0.3g ethanol, 24g toluene diisocyanate, 0.5g phosphorous acid and 60g butyl acetate.

[0018] A kind of preparation method of low free TDI polyurethane polyester resin curing agent is: with 0.98g trimethylol propane, 3.66g neopentyl glycol, 14.53g polyester resin, 0.5g phosphorous acid, 0.3g ethanol, 24.0g toluene Mix diisocyanate and 60g butyl acetate into the pot, dehydrate under reduced pressure for 0.5h, heat up to 58°C, keep warm for 1 hour, cool down to 55°C, then add 0.03g phosphoric acid, 0.2g K54, heat up to 60°C and keep the temperature. After keeping warm for 4 hours, take samples to measure viscosity, NCO and TDI, continue to keep warm until the TDI content is 2.0%, add the remaining 0.06g K5 after cooling down, kee...

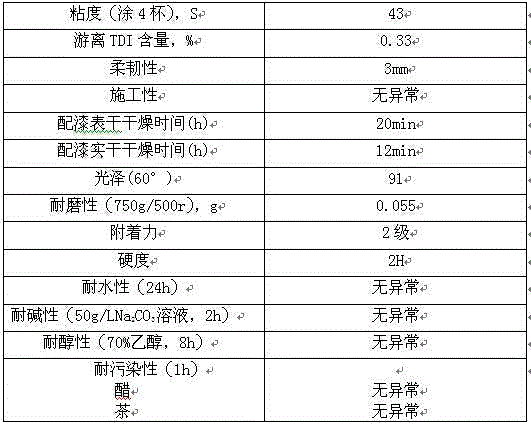

Embodiment 2

[0023] A kind of low free TDI polyurethane polyester resin curing agent described in the present embodiment, it is made of containing weight ratio 14.53g polyester resin, 1.96g trimethylol propane, 2.53g neopentyl glycol, 0.05g phosphoric acid, 0.26gK54, 0.3g ethanol, 24g toluene diisocyanate, 0.5g phosphorous acid and 60g butyl acetate.

[0024] A kind of preparation method of low free TDI polyurethane polyester resin curing agent is: with 1.96g trimethylol propane, 2.53g neopentyl glycol, 14.53g polyester resin, 0.5g phosphorous acid, 0.3g ethanol, 24.0g toluene Mix diisocyanate and 60g butyl acetate into the pot together, dehydrate under reduced pressure for 0.5h, heat up to 58°C, keep warm for 1 hour, cool down to about 55°C, add 0.03g phosphoric acid, 0.2gK54, heat up to 60°C, keep warm After 4 hours, take samples to measure viscosity, NCO, and TDI, continue to keep warm until the TDI content is 3%, cool down and add 0.06g K54, keep warm at 62°C until the measured free TD...

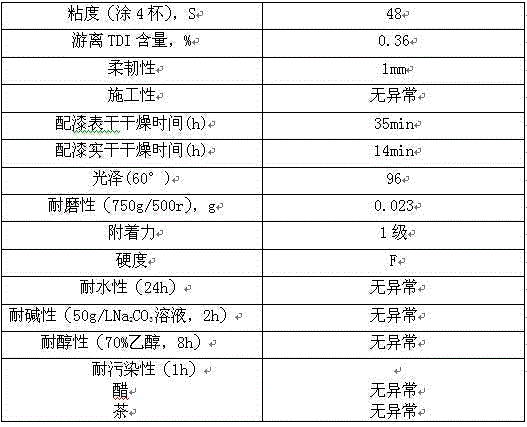

Embodiment 3

[0029] A kind of low free TDI polyurethane polyester resin curing agent described in the present embodiment, it is made of containing weight ratio 29.06g polyester resin, 0.98g trimethylol propane, 2.83g neopentyl glycol, 0.05g phosphoric acid, 0.26gK54, 0.3g ethanol, 24g toluene diisocyanate, 0.5g phosphorous acid and 68g butyl acetate.

[0030] A kind of preparation method of low free TDI polyurethane polyester resin curing agent is: with 0.98g trimethylol propane, 2.83g neopentyl glycol, 29.06g polyester resin, 0.5g antioxidant, 0.3g dehydrating agent, 24.0 Put gTDI and 68g of butyl acetate into the pot together, after dehydration under reduced pressure for 0.5h, heat up to 58°C, keep warm for 1 hour, cool down to about 55°C, add 0.03g phosphoric acid, 0.2gK54, heat up to 60°C and keep warm for 4 Hours later, take samples to measure viscosity, NCO, and TDI, continue to keep warm until the TDI content is 2%, cool down and add 0.06g K54, keep warm at 62°C until the measured f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com