Basophilic micrococcus and alkaline xylanase produced from basophilic micrococcus and application

An alkalophilic micrococcus and xylanase technology, applied in alkaline xylanase and application fields, can solve the problems of incapability of large-scale industrial production of heat-resistant alkaline xylanase, short service life, poor stability and the like, Achieve the effect of being conducive to large-scale fermentation production, inhibiting bacterial contamination, and stabilizing enzyme activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

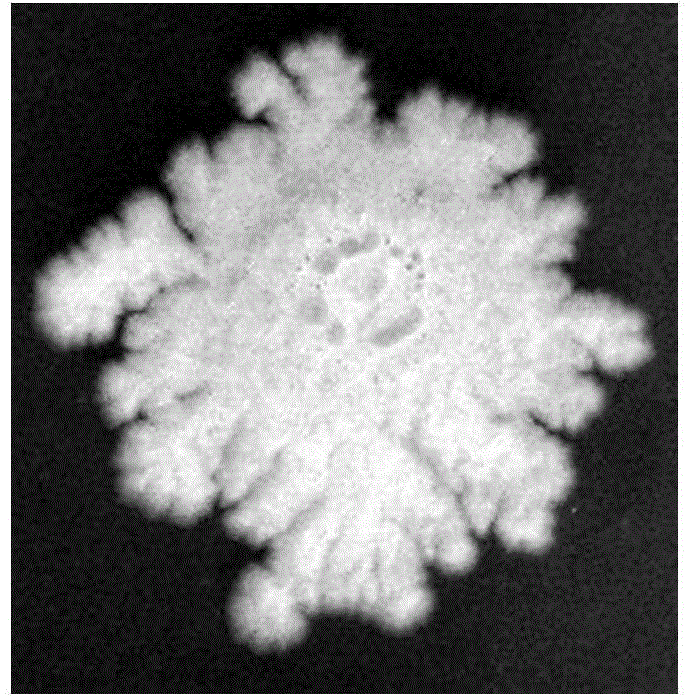

[0050] Example 1 Isolation and cultivation of strains

[0051] 1. Enrichment culture

[0052] The alkaline xylanase-producing strains were screened from Shenzhen mangrove soil. Weigh 1g of soil sample, add it to 100mL of sterile water, shake well to make a bacterial suspension, respectively take 1mL of bacterial suspension and insert it into 5mL enrichment medium that has been sterilized beforehand, at 37℃, 200rpm for enrichment Set culture for 48h.

[0053] Enrichment medium: xylan 8.0g / L, peptone 10g / L, NaCl 15g / L, KH 2 PO 4 1.5g / L, Na 2 HPO 4 ·12H 2 O9.0g / L, MgSO 4 ·7H 2 O 2.0g / L, pH 9.0.

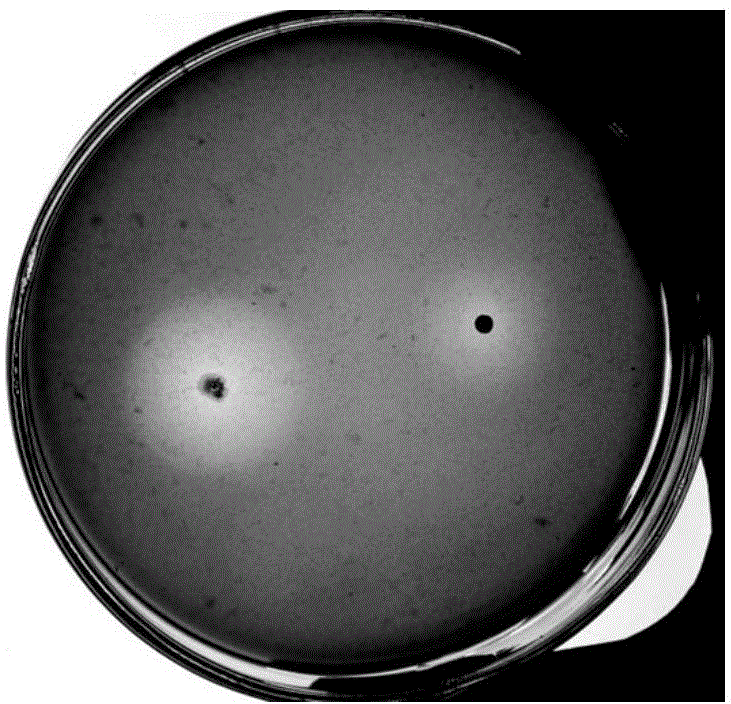

[0054] 2. Flat screen

[0055] Dilute the enriched and cultured bacterial solution by 10 times, and take the dilution factor as 10 -3 , 10 -5 , 10 -7 Spread 0.5 mL of the bacterial suspension on an alkaline selective medium plate containing xylan, and incubate at 37°C for 48 hours. Pick a single colony with a larger transparent circle into the alkaline slant medium. Repeat this many times until...

Embodiment 2

[0064] Example 2 Separation and purification of alkaline xylanase produced by Micrococcus sp.S1

[0065] (1) Materials

[0066] 1. Bacteria

[0067] Alkaliophilic Micrococcus is an alkaline xylanase-producing strain Micrococcus sp.S1 (CCTCC NO:M 2014295) screened from Shenzhen mangrove soil.

[0068] 2. Medium

[0069] Selection medium: Xylan 8.0g / L, KNO 3 1.0g / L, MgSO 4 ·7H 2 O 0.5g / L, NaCl 15g / L, KH 2 PO 4 1.5g / L, solid medium plus 15-20g / L agar, pH 9.0; culture temperature is 37°C.

[0070] 3. Main reagents

[0071] The ion exchange chromatography media DEAE Sepharose Fast Flow and SP-sepharose Fast Flow cation exchange chromatography media were all purchased from GE. Acrylamide and N,N-methylene bisacrylamide are imported from Serva. DNA polymerase and DNA molecular weight markers are products of Bao Biology; protein molecular weight markers are products of Fermentas (MBI); ethylene diamine tetraacetic acid (EDTA), ethylene glycol diethyl ether diamine tetraacetic acid (EGTA), guan...

Embodiment 3

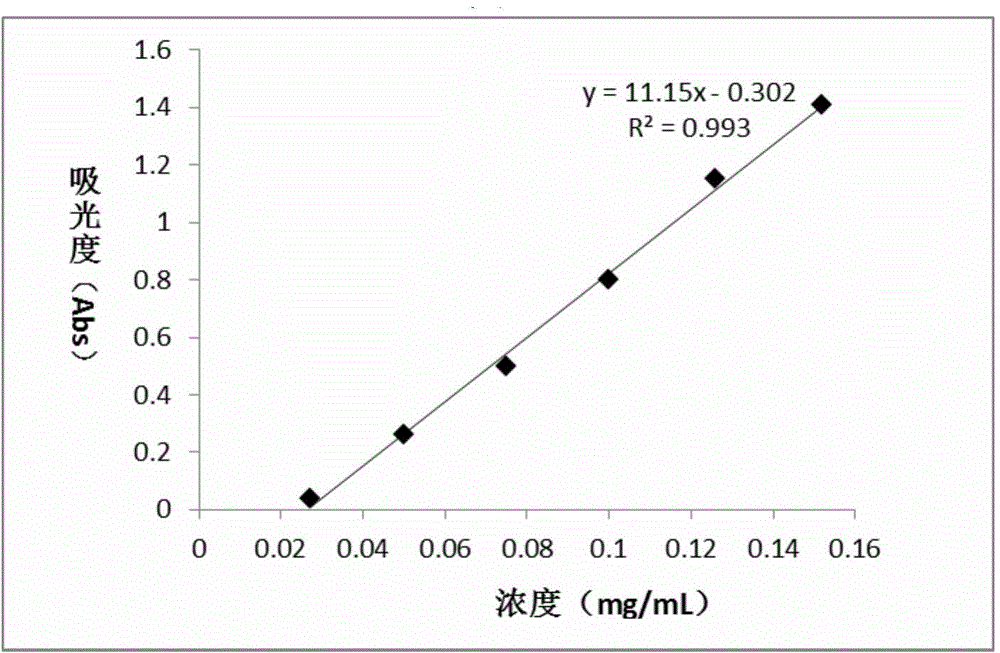

[0094] Example 3 Study on the enzymatic properties of alkaline xylanase

[0095] (1) Test method

[0096] 1. Optimal reaction pH and pH stability

[0097] Take an appropriate amount of the pure enzyme solution of alkaline xylanase obtained in Example 2 and add 1% xylan solutions with different pH values to determine the enzyme activity according to a conventional method. At the same time, the pure enzyme solution was stored under different predetermined pH conditions for 30 minutes, and then the enzyme activity was measured at pH 9.0 according to the conventional method.

[0098] 2. Research on the optimum reaction temperature and temperature stability

[0099] A proper amount of the pure enzyme solution of alkaline xylanase obtained in Example 2 was placed in different temperature conditions and reacted for 20 minutes to determine its enzyme activity. At the same time, the pure enzyme solution was placed under different temperature conditions (30°C to 80°C) for 10 minutes, and then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Protein molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com