Gelatin-based micro-nanofiber membrane material, preparation method and utilization thereof

A technology of micro-nano fibers and nano-fiber membranes, applied in fiber processing, fiber chemical characteristics, rayon manufacturing, etc., can solve problems such as easy water absorption, poor moisture resistance, and easy deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

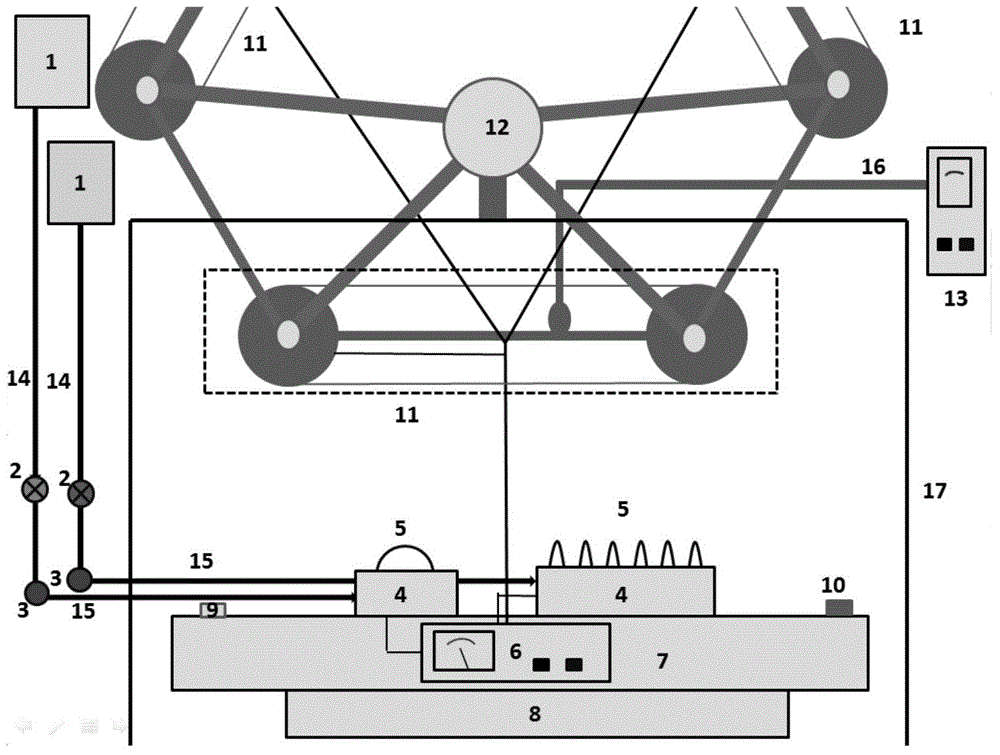

[0078] Such as figure 1 As shown, the screw-type electrospinning machine used to prepare gelatin-based micro-nanofiber membrane materials, it is installed in the cabinet 17 made of acrylic glass with more than two screws made of polytetrafluoroethylene materials. The liquid tank 4 of the sheet type electrospinning machine, and each of the liquid tanks is equipped with a liquid supply pipe 15 made of pp plastic material; and the spiral sheet type electrospinning machine in the adjacent liquid tank The screw spinning head (composed of multiple screws) is placed in a liquid tank in a longitudinal direction of the screw spinning head, and a horizontal direction of the screw spinning head is placed in a liquid tank (such as Figure 7 shown).

[0079] The screw spinning head of the screw type electrostatic spinning machine is installed on the rotating shaft, and the rotating shaft is connected with the transmission part made of polytetrafluoroethylene, and the transmission part is ...

Embodiment 2

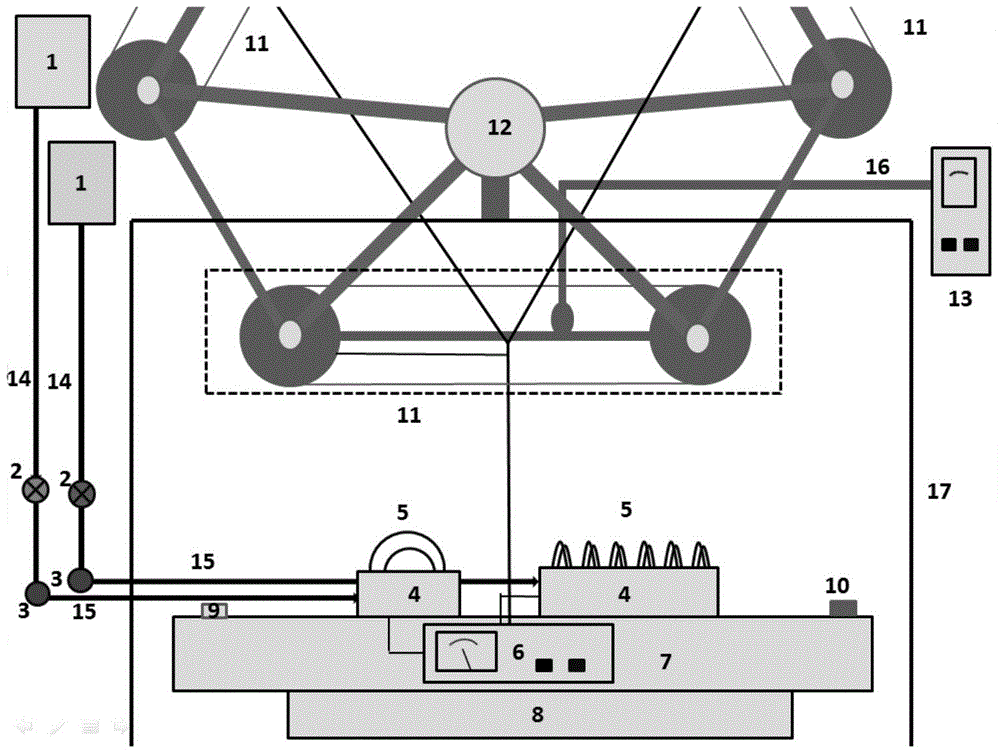

[0093] Such as figure 2 As shown, the structure of the screw electrospinning machine used to prepare the gelatin-based micro-nanofiber membrane material is basically the same as that of the screw electrospinning machine in Example 1, except that the spinning head is replaced, and the screw is spun The head is replaced with a screw spinning head.

[0094] The gelatin-based microfibrous membrane material was prepared using the above-mentioned screw electrospinning machine.

[0095] (1) Use gelatin with a molecular weight of 250,000, dissolve the gelatin in 1wt% acetic acid solution, add chitosan after stirring until completely dissolved, and continue stirring for 48 hours to form a uniform fluid solution to obtain a spinning solution. The content of gelatin is 98wt%, and the content of chitosan is 2wt%; Then the spinning solution is respectively loaded in 4 adjacent liquid tanks of the electrospinning machine, and the spinning solution loaded in the adjacent liquid tanks The ...

Embodiment 3

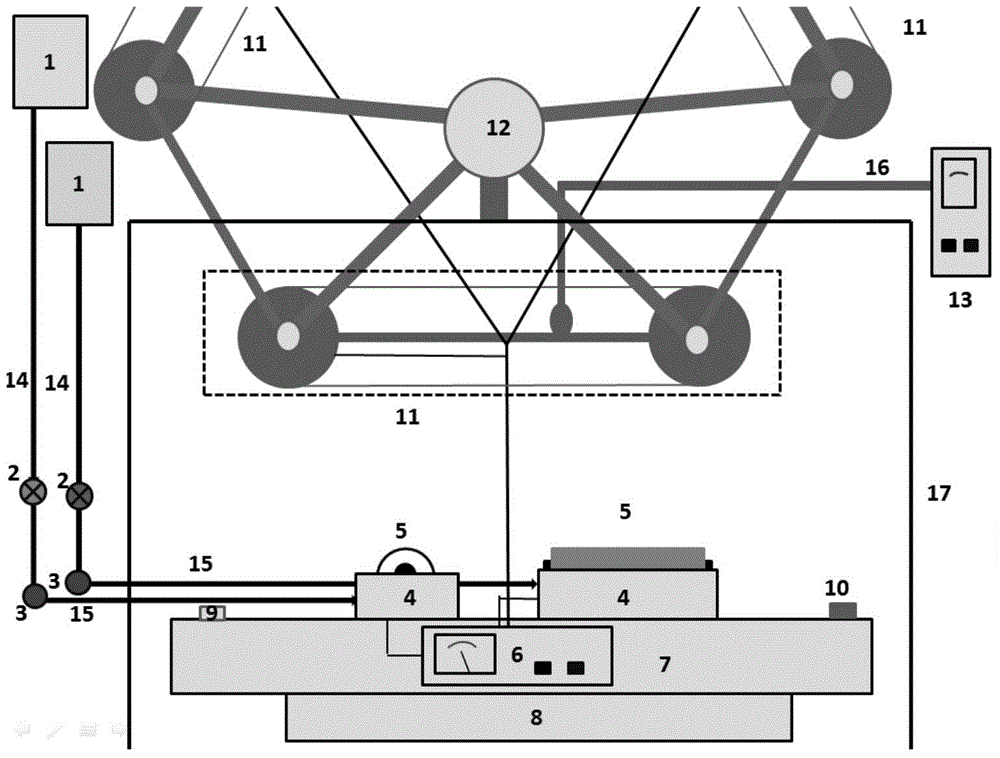

[0103] Such as image 3 As shown, the structure of the drum-type electrospinning machine used to prepare the gelatin-based nanofiber membrane material is basically the same as that of the screw-type electrostatic spinning machine in Example 1, except that the spinning head is replaced, and the screw-type spinning head Change to drum spinning head.

[0104] The gelatin-based nanofibrous membrane material was prepared using the drum-type electrospinning machine described above.

[0105] (1) Use gelatin with a molecular weight of 10,000, dissolve the gelatin in 5wt% ethanol solution, stir until completely dissolved to obtain a gelatin solution; dissolve chitosan in 1wt% acetic acid solution, and stir until completely dissolved to obtain a shell polysaccharide solution; then add calcium alginate to the gelatin solution, and continue stirring for 12 hours to form a uniform fluid solution to obtain a spinning solution containing gelatin; wherein the gelatin content in the spinning ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com