Electric field controlled graphene/gallium arsenide solar cell and preparation method thereof

A solar cell and electric field regulation technology, applied in the field of solar cells, can solve problems such as poor stability and graphene doping, and achieve the effects of high conversion efficiency, simple process, and easy promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

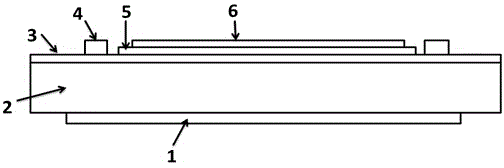

[0027] 1) Electron beam evaporation is used to deposit chromium, nickel and gold composite electrodes on one side of the n-type gallium arsenide wafer;

[0028] 2) Immerse the obtained sample in NaOH aqueous solution with a mass concentration of 10% for surface cleaning, take it out after 30 minutes and dry it;

[0029] 3) transfer the single-layer graphene to the other side of the gallium arsenide sheet after 2) processing;

[0030] 4) Deposit silver electrodes on the graphene layer by thermal evaporation process, and reserve the area for growing insulating dielectric layer;

[0031] 5) Deposit HfO by magnetron sputtering on the area reserved between the silver electrodes on the graphene layer 2 Thin film with a thickness of 5nm;

[0032] 6) In HfO 2 20nm gold is deposited on the film as the gate.

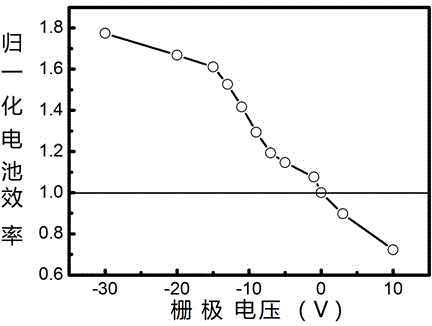

[0033] The effect of the adjusted electric field obtained on the normalized conversion efficiency of graphene / GaAs solar cells is as follows: figure 2 As shown, it can be se...

Embodiment 2

[0035] 1) Deposit titanium, palladium and silver composite electrodes on one side of the p-type gallium arsenide wafer by electron beam evaporation;

[0036] 2) Immerse the obtained sample in HCl aqueous solution with a mass concentration of 10% for surface cleaning, take it out after 5s and dry it;

[0037] 3) Transfer bilayer graphene to 2) the other side of the processed gallium arsenide sheet;

[0038] 4) Deposit the ITO electrode on the graphene layer by using the magnetron sputtering process, and reserve the area for growing the insulating dielectric layer;

[0039] 5) TiO is deposited by magnetron sputtering on the reserved area between the ITO electrodes on the graphene layer 2 Thin film with a thickness of 0.4nm;

[0040] 6) In TiO 2 10nm AZO is deposited on the film as the gate.

Embodiment 3

[0042] 1) Deposit the ITO electrode on one side of the p-type gallium arsenide wafer by magnetron sputtering;

[0043] 2) Immerse the obtained sample in HNO with a mass concentration of 20% 3 Wash the surface in aqueous solution for 5 minutes, take it out and dry it;

[0044] 3) transfer 10 layers of graphene to 2) the other side of the processed gallium arsenide sheet;

[0045] 4) Evaporate gold and palladium composite electrodes on the graphene layer, and reserve the area for growing the insulating dielectric layer;

[0046] 5) Prepare SiN by chemical vapor deposition process on the reserved area of graphene layer x Thin film with a thickness of 100nm;

[0047] 6) In SiN x 80nm FTO is deposited on the film as the gate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com