Organic/polymer solar battery device and preparation method thereof

A technology of solar cells and polymers, applied in semiconductor/solid-state device manufacturing, electric solid-state devices, electrical components, etc., can solve the problem of increasing the cost of organic/polymer solar cell materials, affecting the wide-ranging market application of solar cells, extending materials and Problems such as the device development cycle, to achieve the effect of cumbersome synthesis methods, low cost, and large reserves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

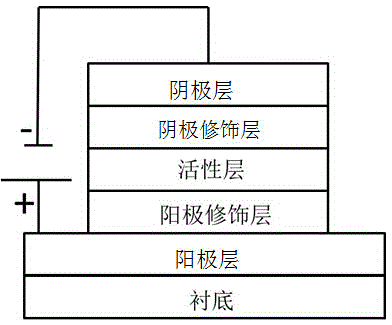

[0032] Fabrication of Upright Organic / Polymer Photovoltaic Devices

[0033] Pre-cut the ITO conductive glass with a sheet resistance of ~20 Ω / □ into 15mm×15mm square pieces. Use acetone, special detergent for micron-sized semiconductors, deionized water, and isopropanol to clean ultrasonically in sequence, and then place it in a constant temperature oven for later use after purging with nitrogen. Before use, clean ITO sheets were bombarded with plasma in an oxygen plasma etcher for 10 minutes. And with PEDOT:PSS aqueous dispersion (aqueous solution with a mass concentration of 1%, purchased from Bayer Company), the buffer layer was spin-coated at a high speed with a homogenizer (KW-4A), and the thickness was determined by the rotational speed. A surface profiler (Tritek Company Alpha-Tencor 500) was measured and monitored, and the final film thickness was 40 nm. After film formation, remove solvent residue and hard film in a constant temperature vacuum oven.

[0034] The co...

Embodiment 2

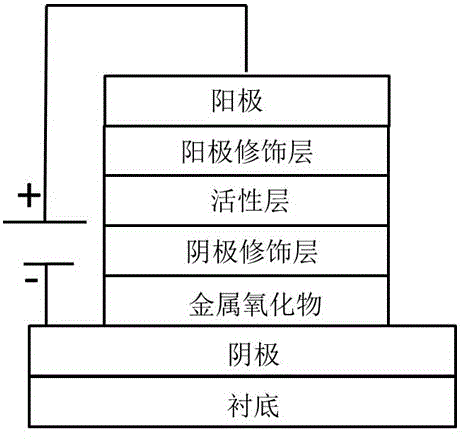

[0036] Fabrication of Inverted Organic / Polymer Photovoltaic Devices

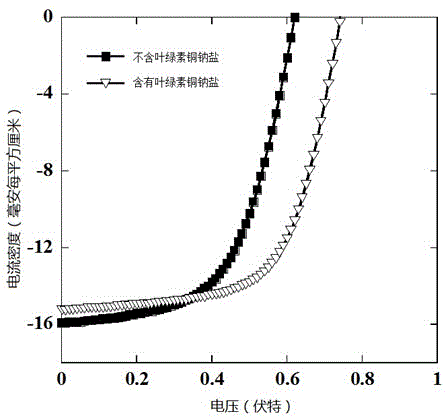

[0037] Pre-cut the ITO conductive glass with a sheet resistance of ~20 Ω / □ into 15mm×15mm square pieces. Use acetone, special detergent for micron-sized semiconductors, deionized water, and isopropanol to clean ultrasonically in sequence, and then place it in a constant temperature oven for later use after purging with nitrogen. Before use, clean ITO sheets were bombarded with plasma in an oxygen plasma etcher for 10 minutes. Then spin-coat a layer of zinc acetate solution on the ITO conductive glass, and then heat treatment at 200 degrees Celsius to form a layer of zinc oxide. The natural pigment derivative copper chlorophyllin sodium salt solution dissolved in methanol solvent is prepared on the zinc oxide film layer by spin coating to form a cathode interface modification layer.

[0038] The conjugated polymer donor material (PTB7: poly(4,8-bis(2-ethylhexyloxy)benzo [1,2-b :4,5-b'] Dithiophene-alterna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com