Preparation method and application of surface carboxylation modified agarose magnetic microspheres

A technology of carboxylation modification and agarose microspheres, which is applied in the preparation of microspheres, chemical instruments and methods, microcapsule preparations, etc., can solve the problems of incomplete elimination of organic pollutants in printing and dyeing wastewater, complicated treatment methods, and high treatment costs. Achieve the effects of large specific surface area, easy recovery, and strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

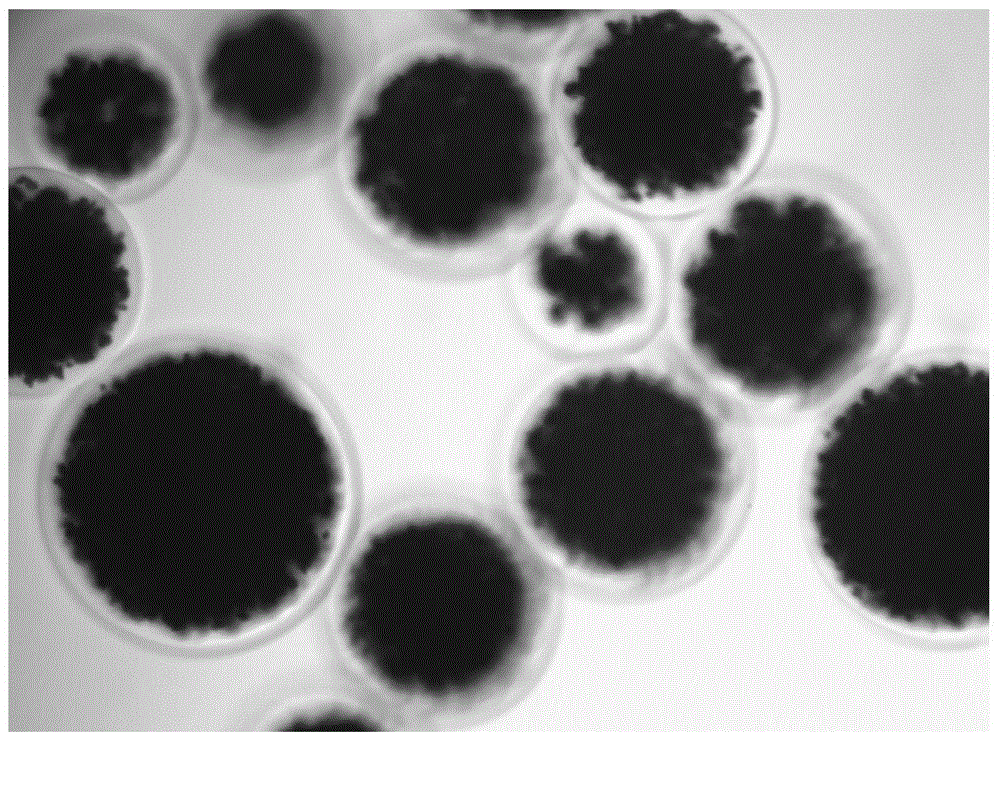

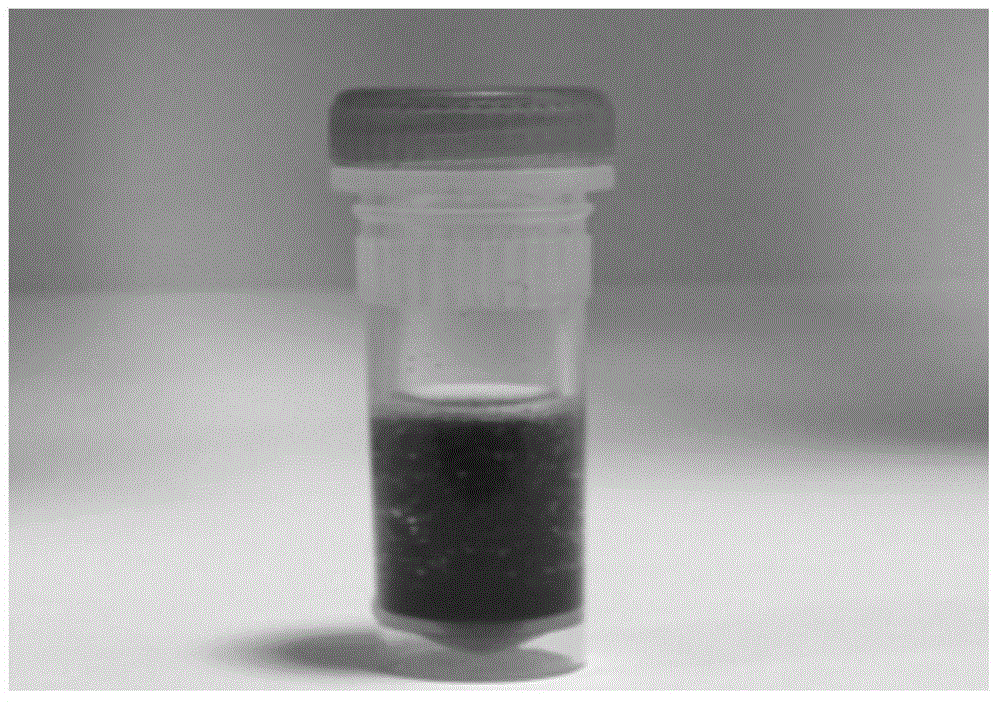

[0039] Specific embodiment one: this embodiment is a kind of preparation method of the agarose magnetic microsphere of surface carboxylation modification is finished according to the following steps:

[0040] 1. Preparation of non-magnetic core agarose microspheres:

[0041] ①. Dissolving agarose in water at a temperature of 50°C to 100°C to obtain an aqueous solution of agarose with a mass fraction of 0.1% to 20% of agarose;

[0042] ②. Use agarose aqueous solution with a mass fraction of 0.1% to 20% of agarose as the water phase W; dissolve the emulsifier into an organic solvent immiscible with water to obtain an oil phase O; combine the water phase W and the oil phase O Mix to obtain a W / O emulsion; then react the W / O emulsion at a temperature of 40°C to 90°C and a rotation speed of 200r / min to 1000r / min for 1h to 5h to obtain a W / O emulsion at a temperature of 40°C to 90°C / O emulsion drops; then cool the W / O emulsion drops at a temperature of 40°C to 90°C to 15°C to 40°C...

specific Embodiment approach 2

[0070] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the iron ion mixed solution described in the step 3 is the mixed solution of ferrous chloride solution and ferric chloride solution or ferrous nitrate solution and ferric nitrate Mixture of solutions. Others are the same as the first embodiment.

specific Embodiment approach 3

[0071] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the water described in step ① is ultrapure water. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com