Preparation method and application of TiO2 photocatalytic coating

A technology of titanium dioxide and photocatalysis, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problem of limited thickness of the middle layer, poor bonding force, and coating bonding To improve photocatalytic activity, high reuse, and good binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The steps of the preparation method of titanium dioxide photocatalytic coating are as follows:

[0024] 1) The foamed metal substrate is degreased by absolute ethanol ultrasonically for 10-30 minutes, rinsed with deionized water and soaked in 1M oxalic acid solution for 1-2 hours, then rinsed with deionized water and soaked in 1M sodium hydroxide solution for 1-2 hours , and finally rinse with deionized water and dry in a 40-100°C constant temperature drying oven for later use;

[0025] 2) Adjust the pH of 50-100mL absolute ethanol, 50-100mL deionized water, 1-10mL tetramethyl silicate or tetraethyl silicate, and 2M nitric acid solution to 2.0-5.0, stir at room temperature for 6-24 hours, and prepare Obtain precursor solution, stand-by;

[0026]3) Add the prepared precursor solution into the three-electrode tank, use the foamed metal substrate as the working electrode, Ag / AgCl as the reference electrode, and the platinum sheet as the counter electrode, control the pote...

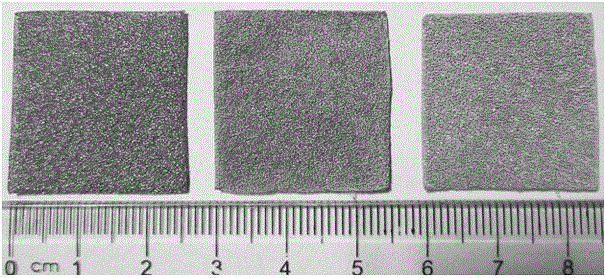

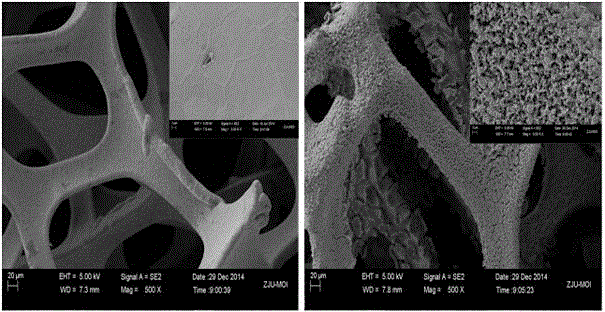

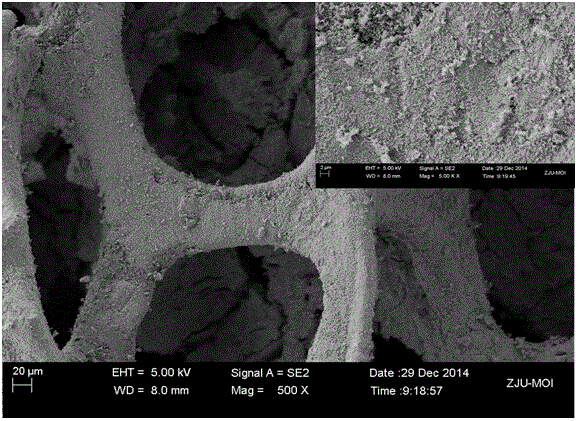

Embodiment 1

[0033] The foamed nickel substrate was degreased by absolute ethanol ultrasonically for 10 minutes, rinsed with deionized water, soaked in 1M sodium hydroxide solution for 1 hour, rinsed with deionized water, soaked in 1M oxalic acid solution for 1 hour, and finally rinsed with deionized water Put it into a constant temperature drying oven at 40°C and dry it for later use.

[0034] Adjust the pH to 2.0 with 50 mL of absolute ethanol, 50 mL of deionized water, 1 mL of tetramethyl silicate or tetraethyl silicate, and 2M nitric acid solution, and stir at room temperature for 6 hours to prepare a precursor solution for use;

[0035] Add the prepared precursor solution into the three-electrode tank, use the nickel foam substrate as the working electrode, Ag / AgCl as the reference electrode, and the platinum sheet as the counter electrode. The control potential is -0.5V, the deposition time is 100s, and the deposition temperature is 30 ℃, rinse with deionized water and ethanol in tur...

Embodiment 2

[0041] The nickel foam substrate was degreased by absolute ethanol ultrasonic for 30 minutes, rinsed with deionized water, soaked in 1M sodium hydroxide solution for 2 hours, rinsed with deionized water, soaked in 1M oxalic acid solution for 2 hours, and finally rinsed with deionized water Put it into a constant temperature drying oven at 100°C and dry it for later use.

[0042] Adjust the pH to 5.0 with 100 mL of absolute ethanol, 100 mL of deionized water, 10 mL of tetramethyl silicate or tetraethyl silicate, and 2M nitric acid solution, and stir at room temperature for 24 hours to prepare a precursor solution for use;

[0043] Add the prepared precursor solution into the three-electrode tank, use the nickel foam substrate as the working electrode, Ag / AgCl as the reference electrode, and the platinum sheet as the counter electrode. The control potential is -5.0V, the deposition time is 1000s, and the deposition temperature is 60 ℃, rinse with deionized water and ethanol in s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com