Preparation method of metal surface graphene/polypyrrole protective composite film

A composite film and metal surface technology, applied in electrolytic inorganic material plating, electrolytic coating, coating, etc., can solve the problems of poor solubility and plasticity of conductive polymers, loss of oxidative properties of polypyrrole films, and restrictions on the application of conductive polymers. Achieve the effects of avoiding difficult dissolution, novel design and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

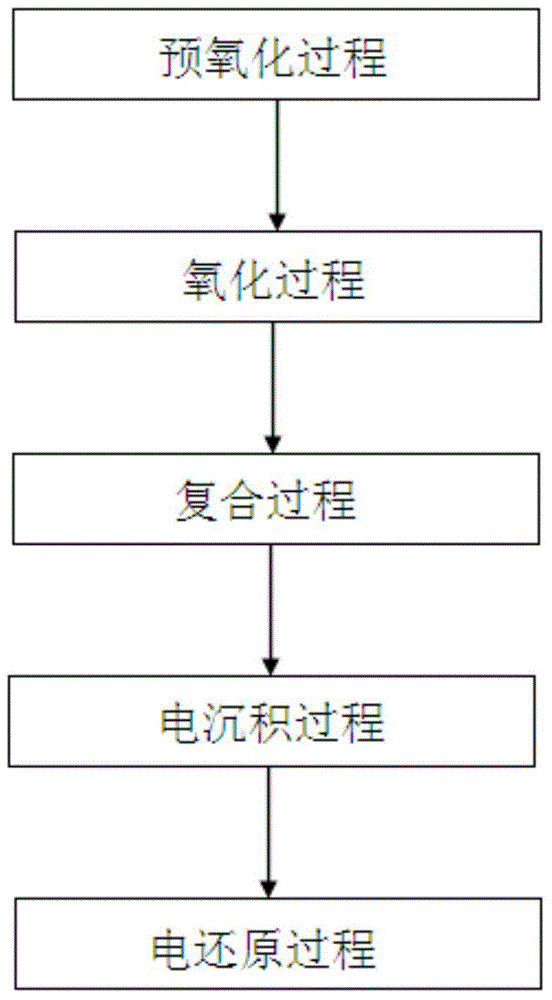

[0020] The specific steps of the preparation method of the metal surface graphene / polypyrrole protective composite film involved in this implementation are:

[0021] (1) Pre-oxidation process: After mixing 2g of natural graphite, 1g of phosphorus pentoxide, 10ml of concentrated sulfuric acid with a mass fraction of 98% and 1g of potassium persulfate and stirring evenly, pre-oxidize at a temperature of 80-90°C for 0.5-18h, Then cool naturally to room temperature (20-25°C) and place for 6-8h, then add distilled water to dilute, filter with suction and wash with water until neutral, and obtain pre-oxidized graphite after drying;

[0022] (2) Oxidation process: After mixing and stirring the pre-oxidized graphite and 46ml concentrated sulfuric acid evenly, use an ice bath device to control the reaction system, slowly add 6g of potassium permanganate powder under the condition of 10-20°C and keep stirring, then put the reaction system on the Stir and react in an oil bath at 35-38°C ...

Embodiment 2

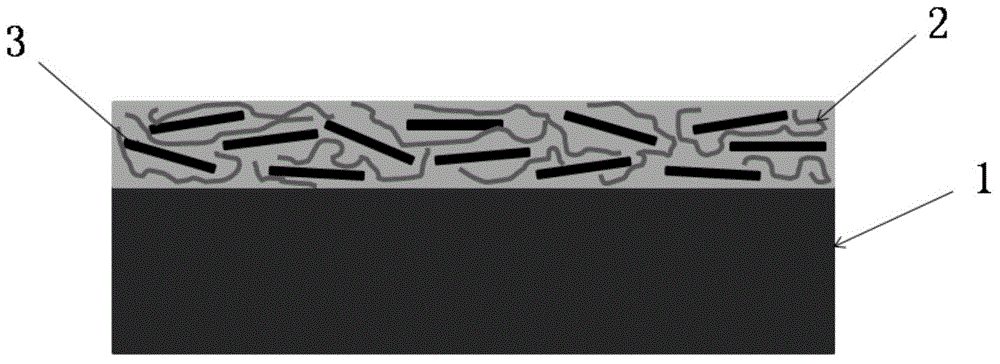

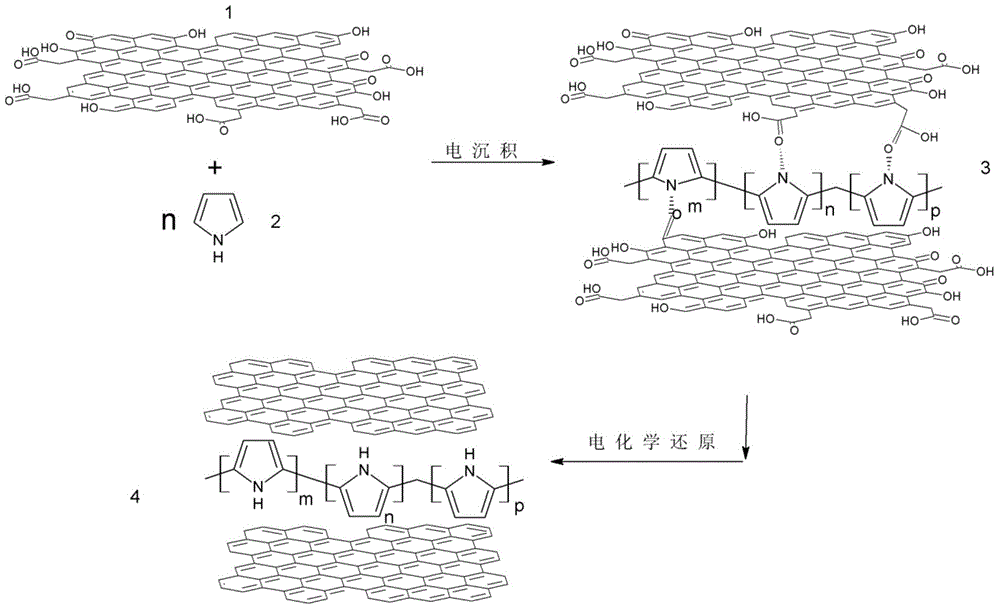

[0028] Take 20 mg of graphene oxide (or measure a certain volume according to the concentration of the calibrated graphene oxide dispersion (quantitatively to about 1 mg / ml)), and use an ultrasonic cleaner to sonicate for 15 to 20 minutes to obtain a uniform graphene oxide dispersion. Liquid; measure 20mg pyrrole monomer, add dropwise in the above-mentioned graphene oxide dispersion liquid, make the weight ratio of graphene oxide and pyrrole 1:1, obtain uniform graphene oxide pyrrole dispersion liquid (abbreviation dispersion liquid) through magnetic stirring , Nitrogen was passed through the above dispersion liquid for 30 min; carbon steel sheet, saturated silver chloride electrode and platinum electrode were put into the dispersion liquid, and a voltage of 0.8 V was applied for 5 min by using an electrochemical workstation (Shanghai Chenhua CHI 760D type). Form a graphene / polypyrrole protective composite film (hereinafter referred to as the composite film) on the surface of t...

Embodiment 3

[0030] Take 20 mg of graphene oxide (or measure a certain volume according to the concentration of the calibrated graphene oxide dispersion (quantitatively to about 1 mg / ml)), and use an ultrasonic cleaner to sonicate for 15 to 20 minutes to obtain a uniform graphene oxide dispersion. Liquid; measure 20mg pyrrole monomer, add dropwise in the above-mentioned graphene oxide dispersion liquid, make the weight ratio of graphene oxide and pyrrole 1:1, obtain uniform graphene oxide pyrrole dispersion liquid (abbreviation dispersion liquid) through magnetic stirring , Nitrogen was passed through the dispersion liquid for 30 min; copper flakes, saturated silver chloride electrodes and platinum electrodes were put into the dispersion liquid, and a voltage of 1.2 V was applied for 1 min by using an electrochemical workstation (Shanghai Chenhua CHI 760D type), and the electrodeposited Form a graphene / polypyrrole protective composite film (hereinafter referred to as the composite film) on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com