Preparation method and application of glycocyamine complex

A technology of guanidinoacetic acid and complexes, which is applied in the field of preparation of feed additives, can solve the problems of affecting energy utilization efficiency, potential value of animal feeding, and immeasurable impact, so as to avoid environmental pollution and sewage treatment burden, and improve absorption and utilization. rate, the effect of improving the reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

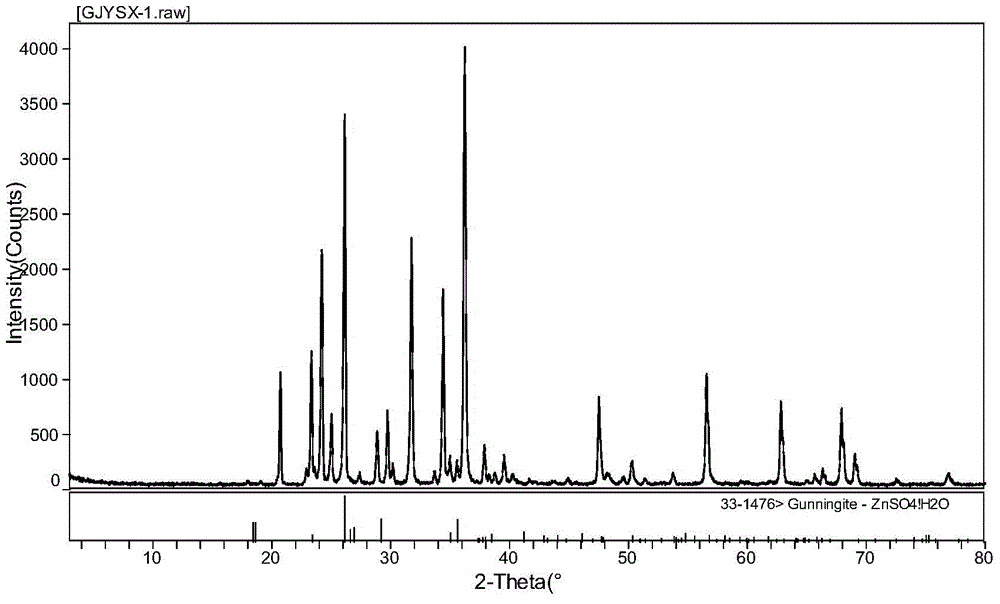

[0052] Embodiment 1: the preparation of zinc guanidine acetate

[0053] A preparation method for the zinc guanidine acetate complex used as an animal feed additive, comprising the following steps:

[0054] Add 300Kg of mother liquor into the jacketed reaction kettle, open the stirring device and steam valve, heat to the reaction temperature of 50°C, add 182Kg of zinc sulfate monohydrate (purity: 98%), continue stirring for 15min until the materials are completely dissolved, and then add 246Kg guanidinoacetic acid (purity: 99%), slowly adjust the pH value of the reaction system with 5% concentration of sodium hydroxide solution to be 8.2, heat up to 40°C and stir for 30min, until the reaction is complete, close the steam valve, and pass through the jacket. into the ground water and cooled to 30°C for crystallization. After the crystallization is completed, discharge and press filter, and flash dry to obtain 272Kg of zinc guanidinoacetate in the solid phase. The next batch of r...

Embodiment 2

[0056] Embodiment 2: the preparation of zinc guanidine acetate

[0057] A preparation method for the zinc guanidine acetate complex used as an animal feed additive, comprising the following steps:

[0058] Add 500Kg of water into the jacketed reaction kettle, open the stirring device and steam valve, heat to the reaction temperature of 70°C, add 211Kg of zinc oxide (purity: 96%), continue stirring for 15min until the material is completely dissolved, and then add 603Kg of guanidine Glycoacetic acid (purity: 99%), heated up to 80°C and stirred for 2 hours. The pH value of the reaction system was 8.6. After the reaction was complete, the steam valve was closed, and ground water was passed into the jacket to cool to 30°C for crystallization. After the crystallization was completed, the The material was press-filtered and flash-dried to obtain 731Kg of zinc guanidinoacetate as a solid phase substance, and the liquid phase was used as the initial mother liquor of the next reaction ...

Embodiment 3

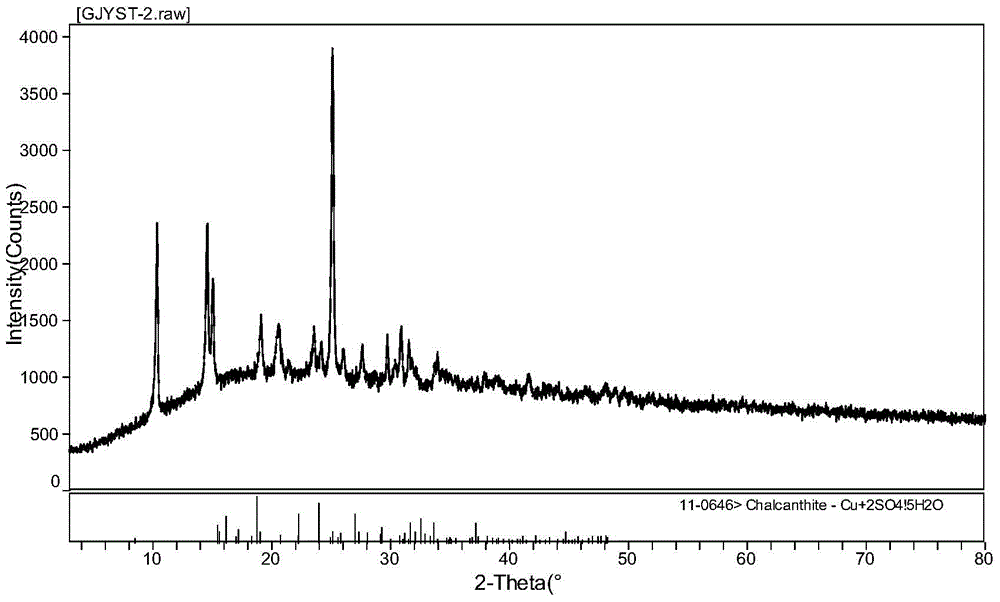

[0060] Embodiment 3: the preparation of guanidine copper acetate

[0061] A preparation method for a guanidine copper acetate complex as an animal feed additive, comprising the following steps:

[0062] Add 300g of the mother liquor of the previous batch of reactions to a 500ml beaker and place it in a 75°C constant temperature water bath, turn on the stirring device, weigh 118g of guanidinoacetic acid (purity: 99%), continue to stir for 10min, and then add 117g of basic chlorination Copper (purity: 99%), slowly adjust the pH value of the reaction system to 10.5 with potassium hydroxide with a concentration of 8%, continue to slowly stir the reaction in a 70°C water bath for 40min, until the reaction is complete, turn off the power supply of the constant temperature water bath, and cool down naturally , the reaction system was naturally cooled and crystallized in a water bath. When the temperature was cooled to 25°C, the beaker was taken out to filter the reaction product. Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com