Biomimetic catalytic carbon fiber and preparation method thereof

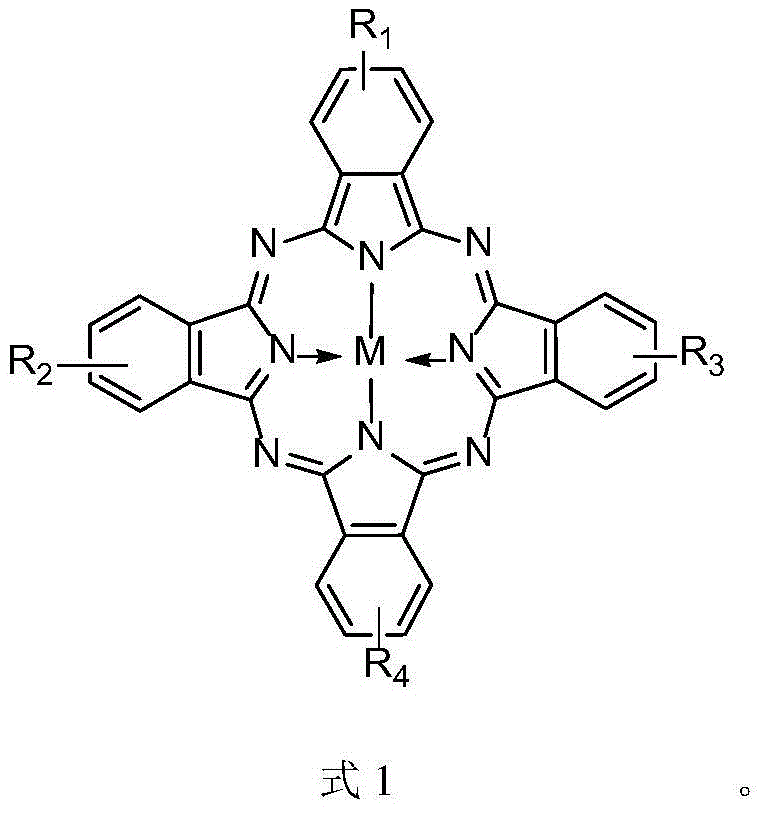

A biomimetic catalytic carbon and carbon fiber technology, which is applied in the fields of materials, chemistry and chemical industry, can solve the problems of affecting the catalytic performance of catalysts, complex preparation routes, unfavorable electron transport, etc., and achieve good application prospects, good chemical stability and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

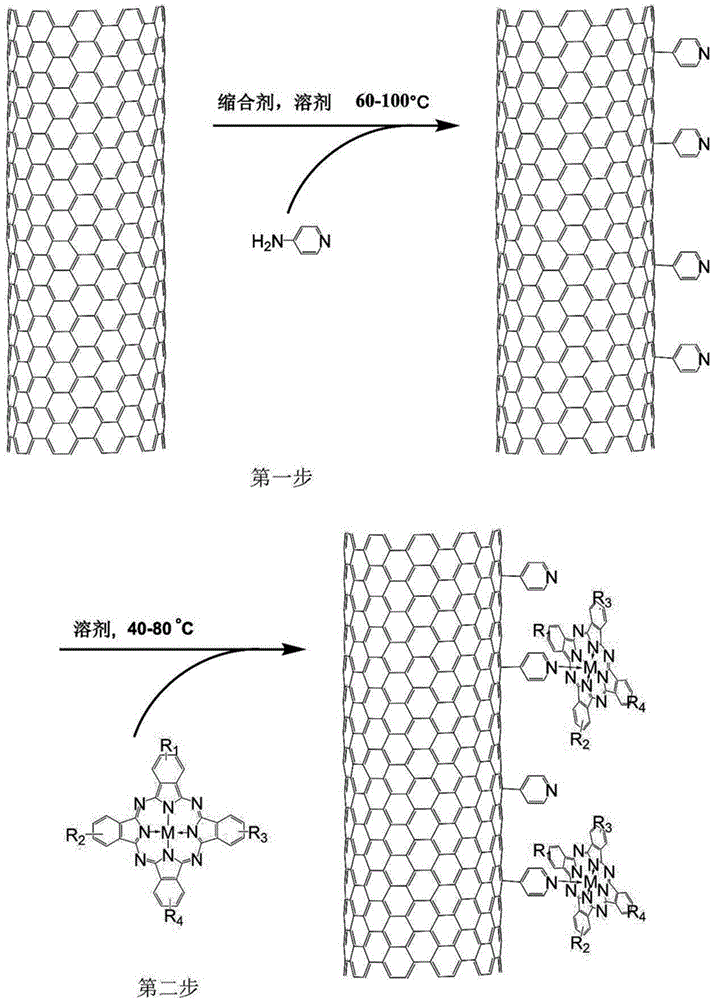

Method used

Image

Examples

Embodiment 1

[0024] A kind of preparation method of biomimetic catalytic carbon fiber, its concrete steps are:

[0025] Weigh 0.5g of 4-aminopyridine and fully dissolve it in dimethyl sulfoxide, ultrasonically dissolve it and add it into the dimethyl sulfoxide solution containing 1.0g of carbon fiber, stir vigorously in an oil bath at 60°C until the temperature rises to 60°C Then add the condensing agent isoamyl nitrite dropwise, react at 60°C for 48 hours, and finally remove the reaction solution, take out the carbon fibers loaded with pyridine groups, and wash them repeatedly with N,N-dimethylformamide, water, and ethanol. Dry at 80°C to obtain modified carbon fibers containing pyridine groups; then, at a reaction temperature of 40°C, disperse the modified carbon fibers and 0.01 g of unsubstituted cobalt phthalocyanine in tetrahydrofuran, mix thoroughly, and stir for 48 hours, after the reaction was completed, the carbon fiber loaded with cobalt phthalocyanine was taken out, washed with ...

Embodiment 2

[0027] A kind of preparation method of biomimetic catalytic carbon fiber, its concrete steps are:

[0028]Weigh 4.5g of 4-aminopyridine and fully dissolve it in N,N-dimethylformamide, ultrasonically dissolve it, add it to N,N-dimethylformamide containing 2.4g of carbon fiber, stir vigorously in an oil bath at 60°C After the temperature rises to 60°C, add the condensing agent isoamyl nitrite dropwise, react at 60°C for 48 hours, and finally remove the reaction solution, take out the modified carbon fiber containing pyridine groups, and use N,N-dimethyl formaldehyde Amide, water, and ethanol were washed repeatedly, and dried at 90°C to obtain modified carbon fibers; then, at a reaction temperature of 80°C, the modified carbon fibers and 0.45 g of tetranitronickel phthalocyanine were dispersed in N-methylpyrrolidone , fully mixed, stirred and reacted for 24 hours. After the reaction was completed, the carbon fiber loaded with nickel phthalocyanine was taken out, washed with N-met...

Embodiment 3

[0030] A kind of preparation method of biomimetic catalytic carbon fiber, its concrete steps are:

[0031] Weigh 5.0g of 4-aminopyridine and fully dissolve it in dimethyl sulfoxide. After ultrasonic dissolution, add it to the dimethyl sulfoxide solution containing 5.0g of carbon fiber. Stir vigorously in an oil bath at 85°C until the temperature rises to 85°C Then add the condensing agent isoamyl nitrite dropwise, react at 85°C for 24 hours, finally remove the reaction solution, take out the modified carbon fiber containing pyridine groups, and wash it repeatedly with N,N-dimethylformamide, water and ethanol , and dried at 100°C to obtain modified carbon fiber; then, under the condition of reaction temperature of 65°C, respectively, the modified carbon fiber and 5.0 g of unsubstituted iron phthalocyanine were dispersed in tetrahydrofuran, mixed thoroughly, stirred and refluxed for 15 hours, and the reaction After the completion, the carbon fiber loaded with iron phthalocyanine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com