A method for treating reverse osmosis concentrated water with catalytic internal electrolysis-improved biological aerated filter

An aerated biological filter, reverse osmosis concentrated water technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of secondary pollution and high energy consumption, Achieve the effect of low operating cost, low power consumption and low aeration volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

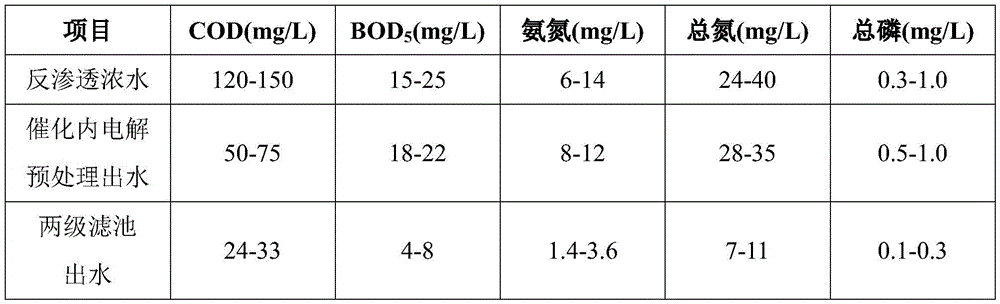

[0028] The reverse osmosis concentrated water treatment of a sewage treatment plant in Jiangsu Province is shown in Table 1.

[0029] Table 1 Process inlet and outlet water quality

[0030]

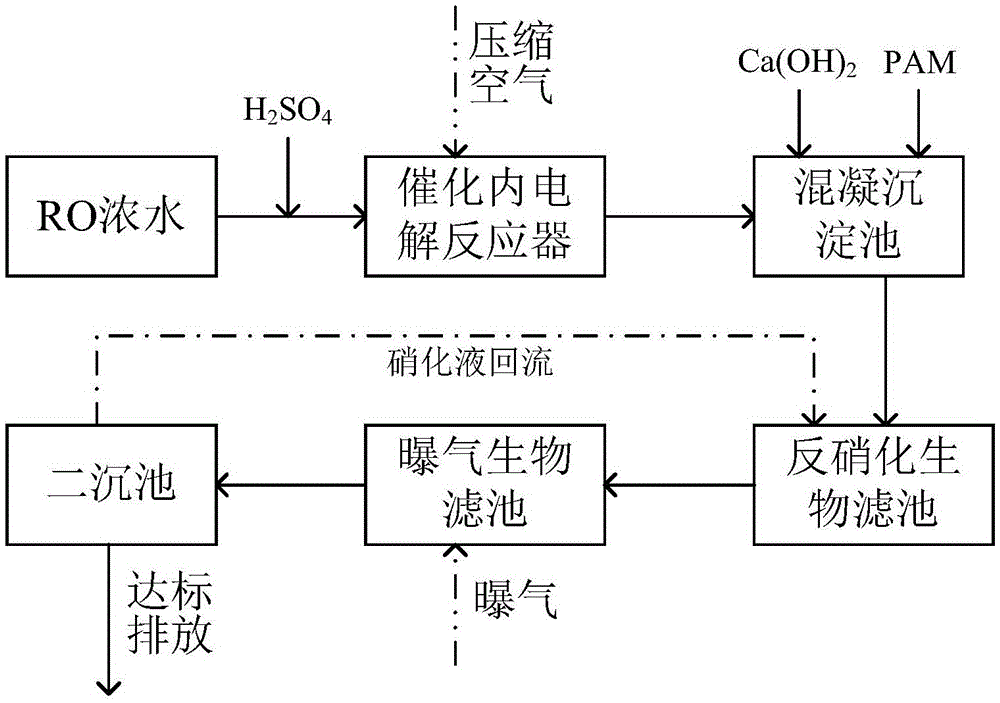

[0031] A, Catalyzed internal electrolytic pretreatment

[0032] Use sulfuric acid to adjust the pH value of the reverse osmosis concentrated water to 2-3, enter the catalytic internal electrolysis reactor for aeration, control the dissolved oxygen concentration at 2-3mg / L, and the residence time is 2h. After pretreatment, enter the coagulation sedimentation tank, add lime to adjust the pH value = 8-9, and then add flocculant PAM. The dosage of lime and PAM is 100mg / L and 2mg / L respectively.

[0033] In this embodiment, the preparation method of the iron-carbon micro-electrolytic filler used is: the weight ratio of iron filings and powdered activated carbon is about 5.66:1, and adding rare earth metal powder accounting for no more than 0.1% of the total weight, after bonding and sinte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com