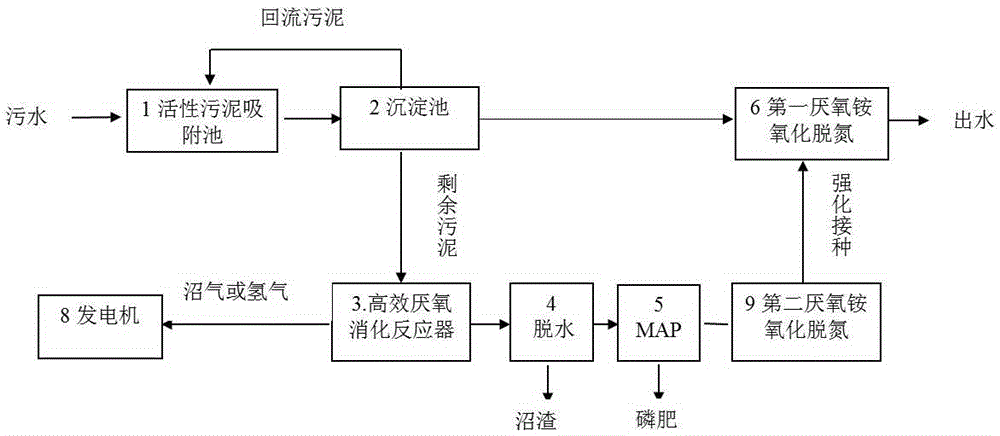

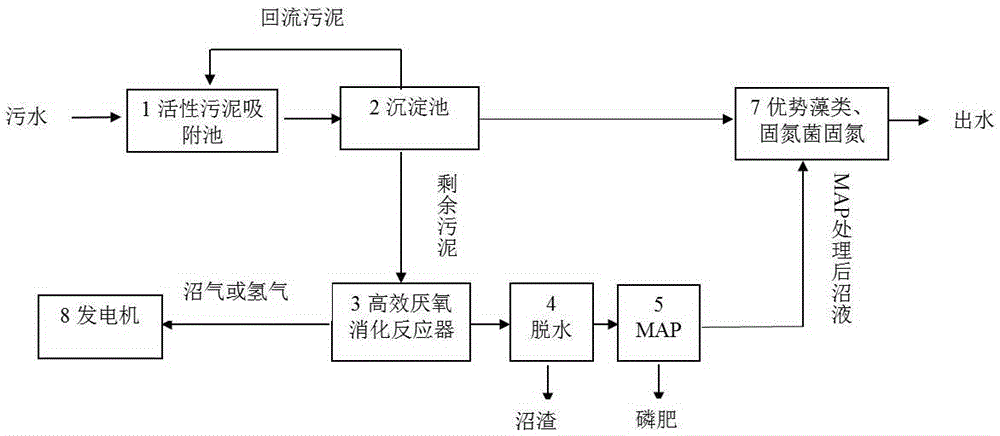

A sewage treatment method with high efficiency, energy saving, consumption reduction and resource recovery

A sewage treatment method and resource recovery technology, which is applied in the field of sewage treatment with high efficiency, energy saving, consumption reduction and resource recovery, can solve the problems of increasing system complexity, increasing infrastructure and operating costs, and unstable nitrification effect of the system, so as to improve free ammonia Inhibition of denitrification, avoiding insufficient carbon sources for denitrification, and improving the effect of relative insufficient carbon sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A set of small-scale test equipment is adopted. Under the continuous operation mode, the sewage enters the activated sludge adsorption tank 1, and enters the sedimentation tank 2 after completing the adsorption reaction to realize the separation of mud and water. The supernatant flows into the next processing unit, and most of the sludge returns. A small part is exhausted from the system. The sludge concentration in the activated sludge adsorption tank 1 is maintained at about 3000mg / L. The hydraulic retention time of the adsorption tank is 35min, the SRT is 0.75 days, and the hydraulic retention time of the sedimentation tank 2 is 2h. The remaining sludge enters the 6.0L high-efficiency anaerobic digestion reactor to produce methane. In the start-up stage of the high-efficiency anaerobic digestion reactor, after adding inoculum sludge, a certain volume of dewatered sludge is fed into the high-efficiency anaerobic digestion reactor every day, and the organic load is g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com