A high specific gravity and low consistency water dispersion resistant synchronous grouting material

A simultaneous grouting and water-resistant dispersion technology, applied in the field of building materials, can solve the problems that natural sand is difficult to guarantee infrastructure construction and affect engineering progress, etc., achieve good injectability, improve work performance, and increase friction and shear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

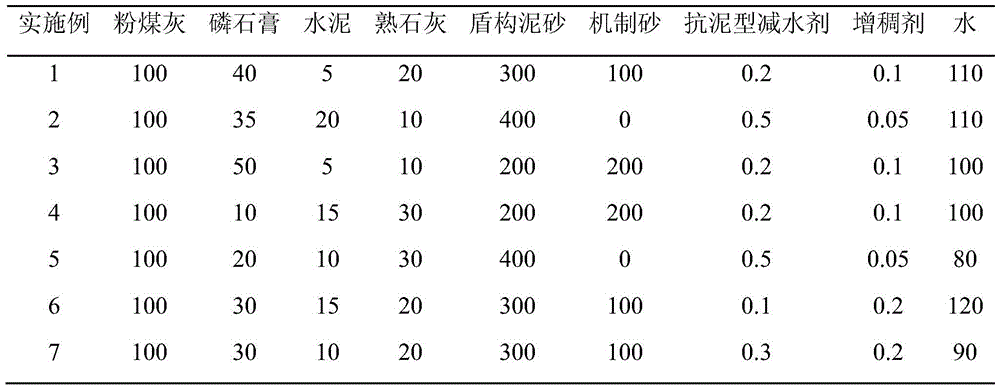

[0060] A water-resistant dispersion synchronous grouting material with large specific gravity and low consistency, which consists of the following components in parts by weight:

[0061] 100 parts of fly ash, 40 parts of phosphogypsum, 5 parts of cement, 20 parts of slaked lime, 300 parts of shield mud sand, 100 parts of machine-made sand, 0.2 parts of water reducer, 0.1 part of thickener, and 110 parts of water.

[0062] The shield silt has a water content of 4.6%, a mud content of 12.6wt%, a sand content of 86.2wt%, and a fineness modulus of 1.8; the thickener is hydroxypropyl methylcellulose (HPMC) , and its molecular weight is 200,000.

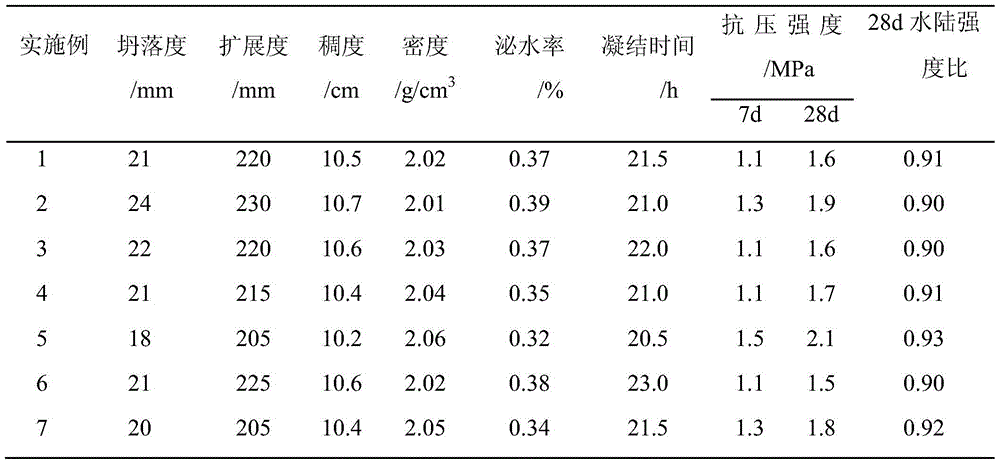

[0063] Table 1 shows the raw material ratio of the large specific gravity, low consistency, water-resistant and dispersible environment-friendly synchronous grouting material described in this example, and the performance test results are shown in Table 2.

Embodiment 2

[0065] A water-resistant dispersion synchronous grouting material with large specific gravity and low consistency, which consists of the following components in parts by weight:

[0066] 100 parts of fly ash, 35 parts of phosphogypsum, 20 parts of cement, 10 parts of slaked lime, 400 parts of shield mud sand, 0 parts of machine-made sand, 0.5 parts of water reducer, 0.05 parts of thickener, and 110 parts of water.

[0067] The slaked lime is industrial-grade white powder with a purity greater than 98%. The shield silt has a water content of 4.6%, a mud content of 12.6wt%, a sand content of 86.2wt%, and a fineness modulus of 1.8; the thickener is hydroxypropyl methylcellulose (HPMC) , and its molecular weight is 200,000.

[0068] Table 1 shows the raw material ratio of the large specific gravity, low consistency, water-resistant and dispersible environment-friendly synchronous grouting material described in this example, and the performance test results are shown in Table 2. ...

Embodiment 3

[0070] A water-resistant dispersion synchronous grouting material with large specific gravity and low consistency, which consists of the following components in parts by weight:

[0071] 100 parts of fly ash, 50 parts of phosphogypsum, 5 parts of cement, 10 parts of hydrated lime, 200 parts of shield mud sand, 200 parts of machine-made sand, 0.2 parts of water reducer, 0.1 part of thickener, and 100 parts of water.

[0072] The shield silt has a water content of 5.3%, a mud content of 20wt%, a sand content of 79.1wt%, and a fineness modulus of 1.6; the thickener is hydroxypropyl methylcellulose (HPMC), Its molecular weight is 200,000.

[0073] Table 1 shows the raw material ratio of the large specific gravity, low consistency, water-resistant and dispersible environment-friendly synchronous grouting material described in this example, and the performance test results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| flow consistency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com