Method for preparing tetrahydrofurfuryl alcohol by liquid phase hydrogenation and catalyst used by method

A technology of tetrahydrofurfuryl alcohol and liquid phase hydrogenation, which is applied in the field of liquid phase hydrogenation, can solve the problems of high production cost and high energy consumption, and achieve the effects of high selectivity, low energy consumption and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation of embodiment 1 catalyst:

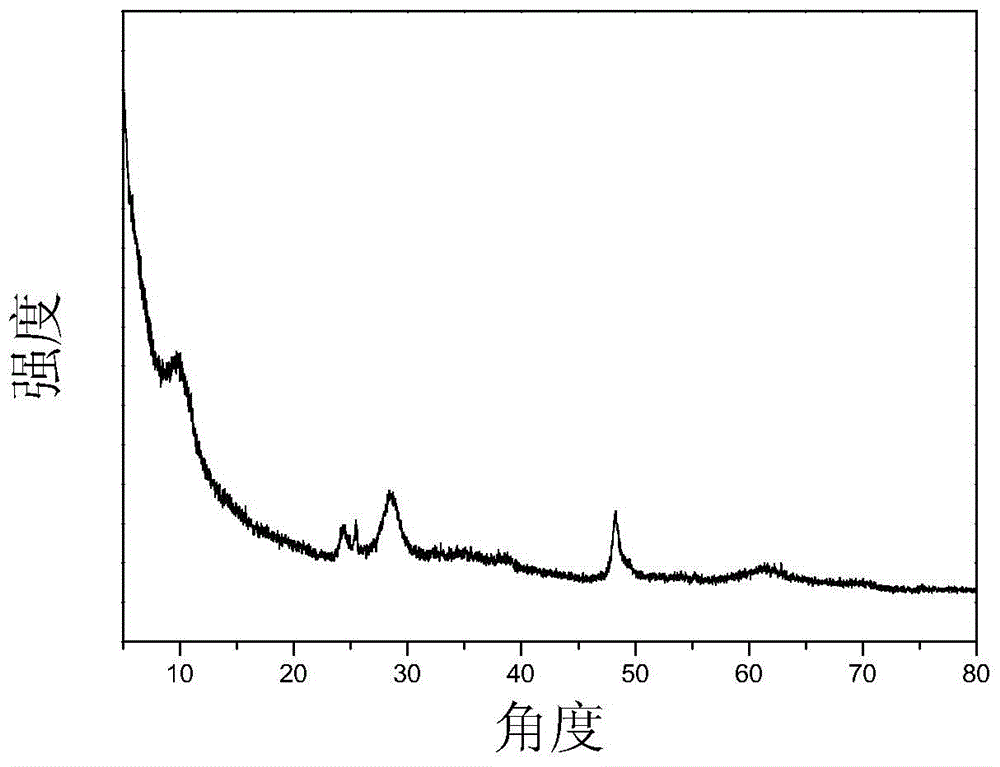

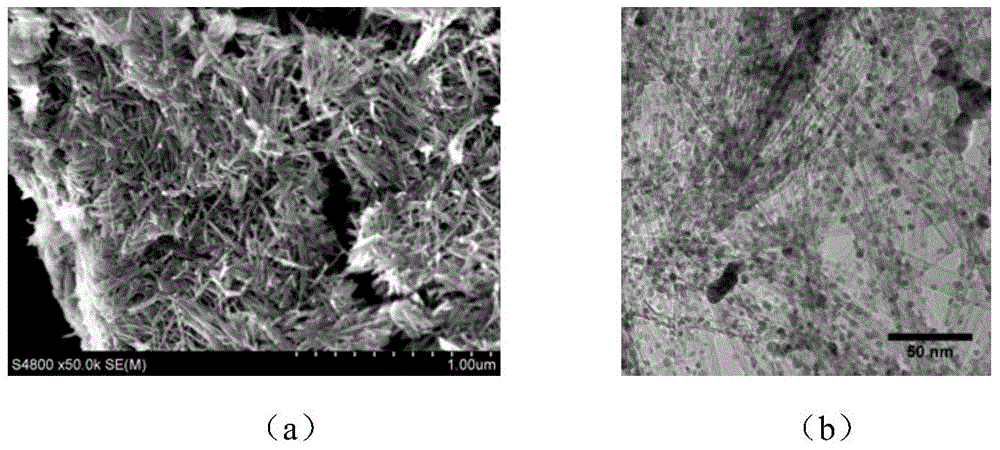

[0032] TiO 2 Add the powder into 5-15M NaOH concentrated solution, react at 100-150°C for 2-3 days, then cool to room temperature, filter and wash with water, then dry to obtain titanium nanotube material, its XRD pattern is as follows figure 1 shown. From figure 2 The SEM image shown in (a) shows that the titanium nanotube material prepared by the present invention is very uniform and has good nanotube morphology.

[0033] Take appropriate amount of PdCl 2 Add the solution into the aqueous solution of titanium oxide nanotubes, stir evenly and adjust the pH to pd 2+ After the precipitation is complete, sodium borohydride is added for reduction and then filtered and dried to prepare a supported palladium catalyst with a specific surface area of 95-120m 2 / g, from figure 2 The TEM image shown in (b) shows that palladium metal nanoparticles are evenly distributed on the carrier, the size of which is in the range of 2-10...

Embodiment 2

[0037] Use the catalyst prepared in Example 1 to carry out the preparation of tetrahydrofurfuryl alcohol by furfuryl alcohol liquid-phase hydrogenation. In the round bottom flask, the catalyst is loaded, and the consumption is about 5% (accounting for furfuryl alcohol mass percent), and the solvent (ethanol) dilution ratio is about 20: 1 (ethanol: furfuryl alcohol, volume ratio), reaction temperature is 25 ℃, under the condition of hydrogen balloon (0.1MPa) reaction 1 hour, conversion rate of furfuryl alcohol is 98%, tetrahydrofurfuryl alcohol selectivity is 98%.

Embodiment 3

[0039]Use the catalyzer prepared in embodiment 1 to prepare tetrahydrofurfuryl alcohol by furfuryl alcohol liquid-phase hydrogenation, under the conditions of the reaction device and reaction temperature and pressure with embodiment 2, catalyst consumption is about 5% (accounting for furfuryl alcohol mass percent), solvent (Isopropanol) dilution ratio is about 20: 1 (isopropanol: furfuryl alcohol, volume ratio), reaction 1 hour, furfuryl alcohol conversion rate 70%, tetrahydrofurfuryl alcohol selectivity 99%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com