Superconducting thin film for single photon detection system and preparation method thereof

A technology of single-photon detection and superconducting thin film, which is applied in the field of single-photon detection, can solve the problems of easy peeling off of the film, uneven surface of the film, short circuit of the circuit, etc., and achieve automatic cutting, no photoresist residue, and convenient and accurate alignment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Preparation of niobium metal superconducting thin film

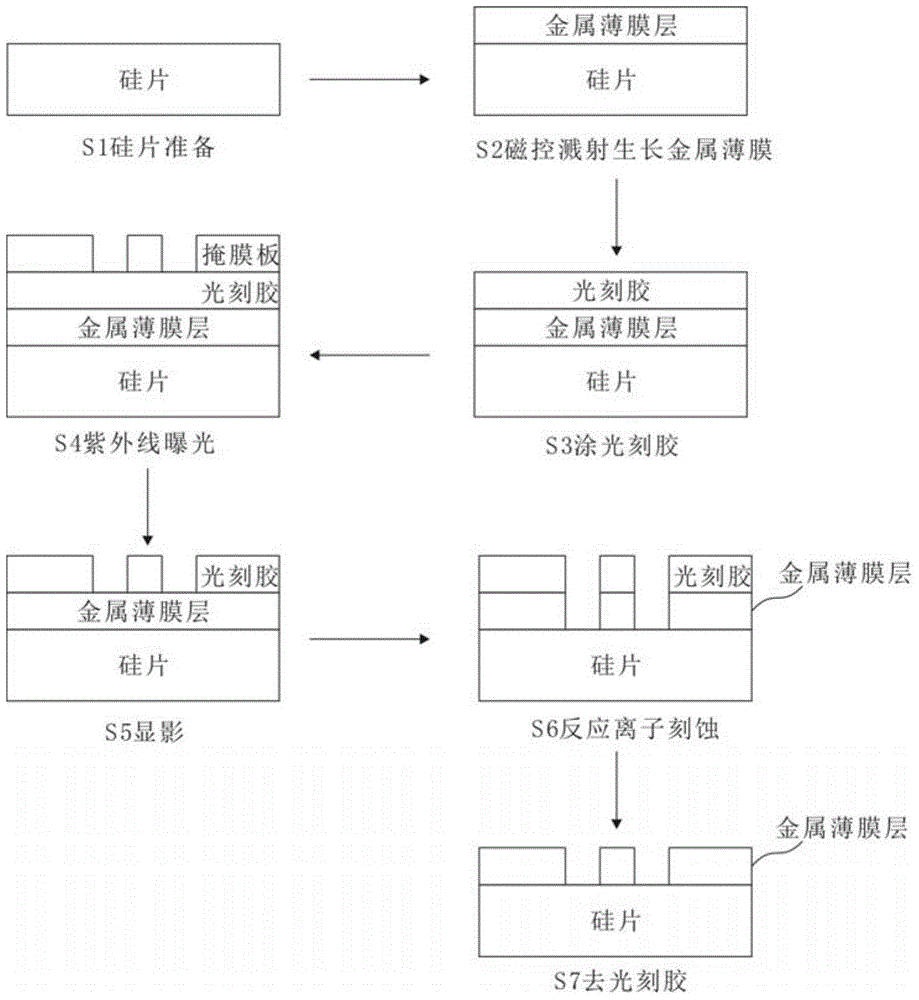

[0028] Such as figure 1 As shown, a method for preparing a niobium metal superconducting thin film for a single photon detection system comprises the following steps:

[0029] S1. Silicon wafer preparation: choose a round silicon wafer with a thickness of 500um and a diameter of 3 inches as the base material, clean the silicon wafer with an ultrasonic oscillator in acetone, ethanol, hydrofluoric acid and ultrapure water, and then air dry;

[0030] S2, grow one layer of niobium metal film on the silicon chip after cleaning, preferably, adopt magnetron sputtering process to grow niobium metal film, control film growth rate by controlling sputtering power size, sputtering power is 100 watts, then The film thickness is controlled by controlling the sputtering time, and the sputtering time is 5 minutes, and a layer of niobium metal film with a thickness of 160 nm is finally grown.

[0031] Compared with or...

Embodiment 2

[0041] Example 2: Preparation of Tungsten Metal Superconducting Thin Film

[0042] Such as figure 1 As shown, a method for preparing a tungsten metal superconducting thin film for a single photon detection system comprises the following steps:

[0043] S1. Silicon wafer preparation: choose a round silicon wafer with a thickness of 500um and a diameter of 3 inches as the base material, clean the silicon wafer with an ultrasonic oscillator in acetone, ethanol, hydrofluoric acid and ultrapure water, and then air dry;

[0044] S2, grow a layer of tungsten metal thin film on the silicon chip after cleaning, preferably, adopt magnetron sputtering technique to grow tungsten metal thin film, control film growth rate by controlling sputtering power size, sputtering power is 50 watts, then The film thickness is controlled by controlling the sputtering time, and the sputtering time is 10 minutes, and a tungsten metal thin film with a thickness of 160 nm is finally grown.

[0045]Compar...

Embodiment 3

[0055] Embodiment 3: Preparation of aluminum metal superconducting thin film.

[0056] Such as figure 1 Shown, a kind of preparation method of the aluminum metal superconducting thin film that is used for single-photon detection system comprises the following steps:

[0057] S1. Silicon wafer preparation: choose a round silicon wafer with a thickness of 500um and a diameter of 3 inches as the base material, clean the silicon wafer with an ultrasonic oscillator in acetone, ethanol, hydrofluoric acid and ultrapure water, and then air dry;

[0058] S2, grow a layer of aluminum metal thin film on the silicon chip after cleaning, preferably, adopt magnetron sputtering process to grow aluminum metal thin film, control film growth rate by controlling sputtering power size, sputtering power is 100 watts, then The film thickness is controlled by controlling the sputtering time, and the sputtering time is 1 minute, and a layer of aluminum metal film with a thickness of 160 nm is finall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com