Preparation method of nano-doped grid patterning gel polymer electrolyte

A grid pattern and electrolyte technology, which is applied in the field of polymer electrolytes and porous polymer electrolyte framework materials, can solve problems such as difficulty in maintaining a stable shape, low gel electrolyte strength, and reduced electrochemical performance, and achieve stable capacity and improved Interface stability, the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

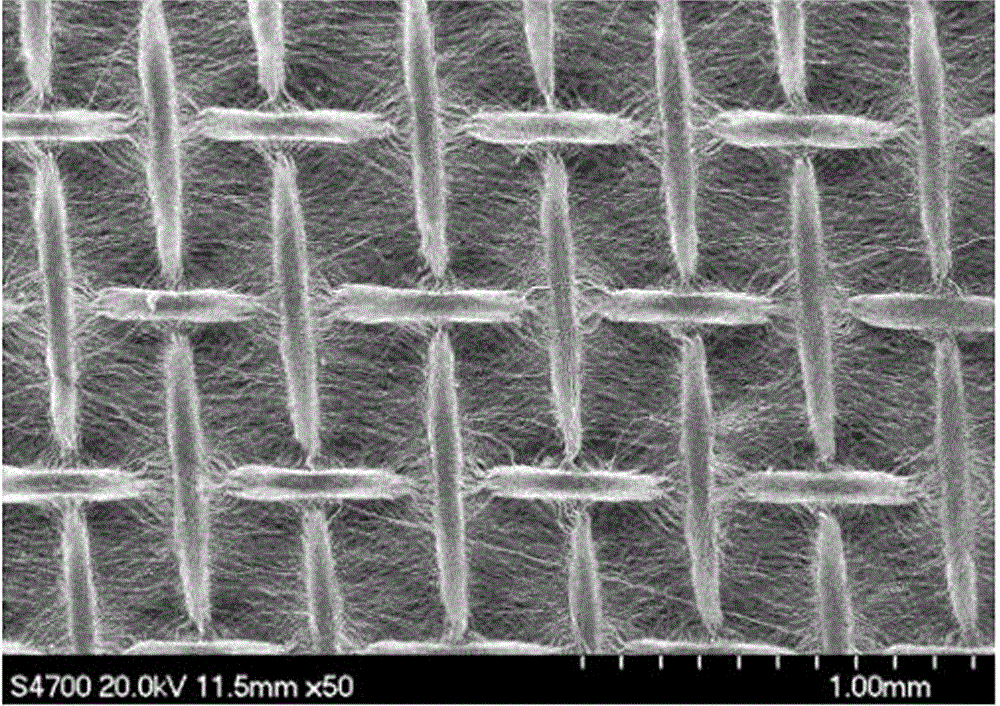

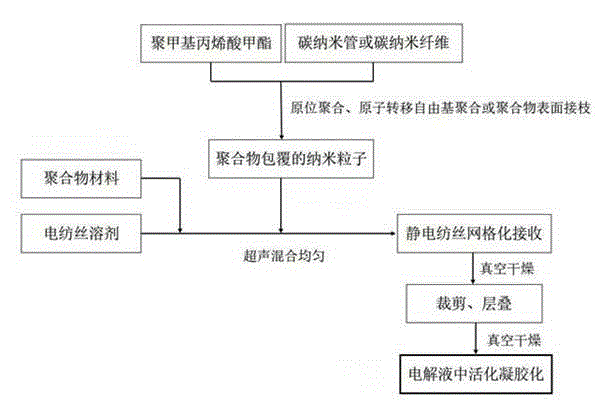

[0028] Component 1: Polyacrylonitrile, molecular weight 10 5 g / mol (Mw), produced by PetroChina Jilin Petrochemical Company. Component 2: self-made carbon nanofiber coated with methyl methacrylate, using VGCF produced by Japan Showa Denko Co., Ltd. TM -S Carbon nanofibers are prepared by in-situ polymerization process. The outer diameter of carbon nanofibers is 50-150nm, the average length is 10μm, and the average thickness of the polymer coating layer is 10nm. Component 3: 1mol / L LiPF 6 / DEC-EC (molar ratio is 1:1) electrolyte, produced by Beijing Chemical Plant. The solvent used in the spinning solution is N,N-dimethylformamide, the concentration of polyacrylonitrile in the spinning solution is 10wt%, the concentration of carbon nanofibers is 5wt%, and the electrospinning collection device adopts 80 mesh plain weave woven brass mesh , sieve size 0.18mm. The polymer fiber membrane obtained by electrospinning was dried in a vacuum oven at 50 °C for 8 h to remove residual ...

Embodiment 2

[0032]Component 1: polyvinylidene fluoride, molecular weight 5.3×105 g / mol (Mw), produced by Shanghai Sanaifu New Materials Co., Ltd. Component 2: Self-made multi-walled carbon nanotubes coated with methyl methacrylate, which were prepared by in-situ polymerization of TNM3 multi-walled carbon nanotubes produced by Chengdu Zhongke Times Nano Co., Ltd., with an outer diameter of 10 ~30nm, the average length is 10μm, and the average thickness of the polymer coating is 10nm. Component 3: 1mol / L LiPF6 / DEC-EC (molar ratio 1:1) electrolyte, produced by Beijing Chemical Plant. The solvent used in the spinning solution is N,N-dimethylformamide, the concentration of polyvinylidene fluoride in the spinning solution is 14wt%, the concentration of multi-walled carbon nanotubes is 3wt%, and the electrospinning collection device adopts a 60-mesh plain weave machine Woven brass mesh, mesh size 0.25mm. The polymer fiber membrane obtained by electrospinning was dried in a vacuum oven at 50 °C...

Embodiment 3

[0036] Component 1: polyethylene oxide, molecular weight 10 5 g / mol (Mw), produced by Shanghai Liansheng Chemical Company. Component 2: Self-made single-walled carbon nanotubes coated with methyl methacrylate, which are produced by TNS single-walled carbon nanotubes produced by Chengdu Zhongke Times Nano Co., Ltd. through an in-situ polymerization process. The outer diameter of the carbon nanotubes is 1 ~2nm, average length 10μm, polymer coating average thickness 10nm. Component 3: 1mol / L LiPF 6 / DEC-EC (molar ratio is 1:1) electrolyte, produced by Beijing Chemical Plant. The solvent used in the spinning solution is N,N-dimethylformamide, the concentration of polyethylene oxide in the spinning solution is 12wt%, the concentration of single-walled carbon nanotubes is 2wt%, and the electrospinning collection device adopts 70 mesh plain weave woven yellow Copper mesh, mesh size 0.22mm. The polymer fiber membrane obtained by electrospinning was dried in a vacuum oven at 50 °C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com