Alkali-soluble resin polymer for color light filter and light-sensitive resin composition

An alkali-soluble resin and color filter technology, which is applied in the fields of optical filters, optics, and optomechanical equipment, can solve the problem that color filters cannot meet the development performance and stability at the same time, and achieve good matching, good Effects of storage safety and superior developing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

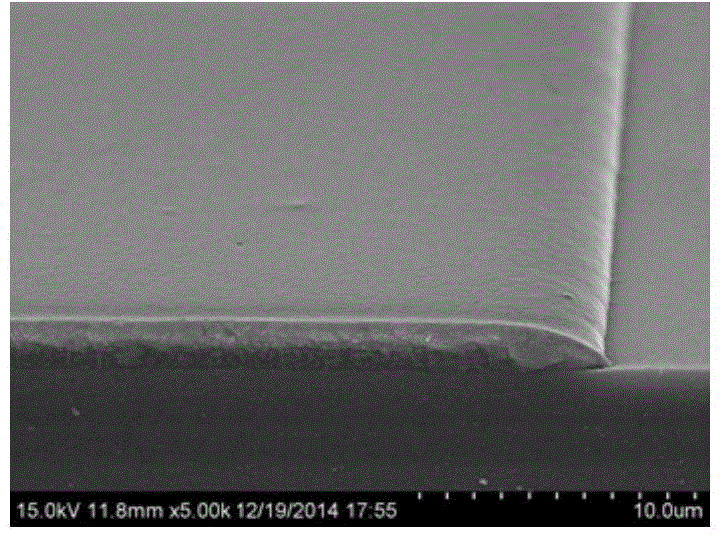

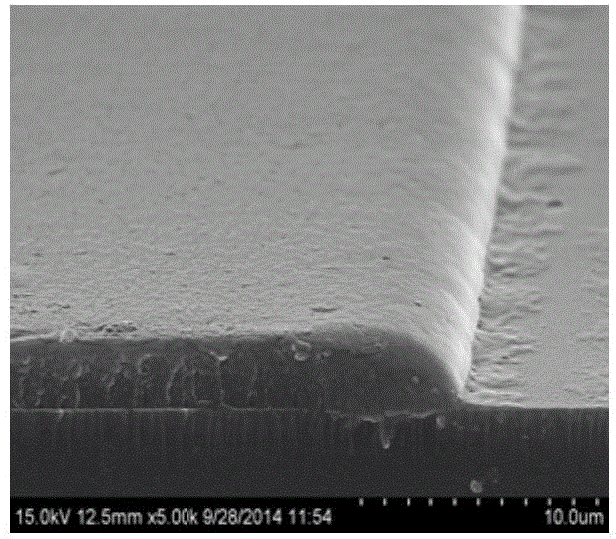

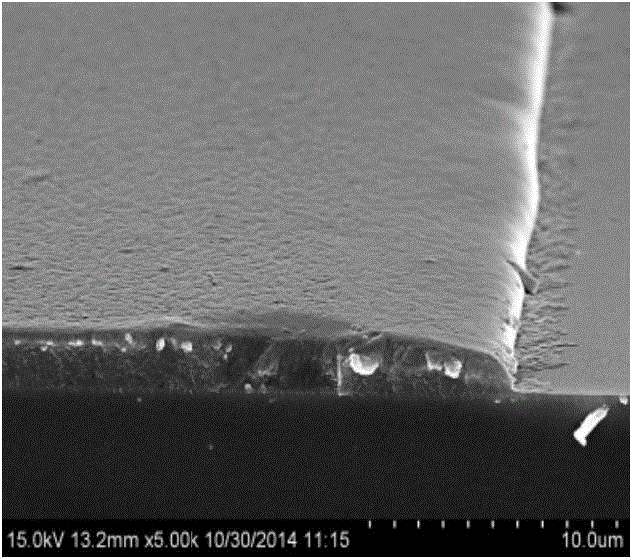

Image

Examples

Synthetic example 1

[0042] Into a 200mL flask, add 10g of monomer M-5400 (Toagosei Co., Ltd.), 20g of monomer M-5700 (Toagosei Co., Ltd.), 35g of benzyl methacrylate, 20g of N-phenylmaleimide, and part of propylene glycol Monomethyl ether acetate, molecular weight regulator (dodecyl mercaptan), under the protection of nitrogen, the system is heated to a predetermined temperature, and under stirring, the azobisisobutyronitrile is dissolved in a constant pressure dropping funnel. The remaining propylene glycol methyl ether acetate solution and 15 g of methacrylic acid were added dropwise into a three-necked flask within 30 minutes, then stirred and reacted at a constant temperature for 3 hours, the temperature was lowered to room temperature, and the solvent was removed to obtain alkali-soluble resins B1-B4 respectively. The weight-average molecular weight and molecular weight distribution of the polymer were measured by GPC, and the acid value was determined by acid-base titration.

[0043] The pr...

Embodiment 1-8

[0057] Taking the alkali-soluble resin polymers B1-B8 synthesized above as examples respectively, the photosensitive resin composition is formulated, and the specific implementation includes the following steps: uniformly dissolving and mixing the components (A)-(F) in a stirrer, controlling The solid content of the system is about 17.5%, and the photoresist is prepared according to the ratio in Table 5. The obtained photosensitive resin compositions were respectively marked as S1-S8, and photolithographic development was carried out to verify the relevant properties of the photosensitive resin compositions.

[0058] The lithographic imaging method using the photosensitive resin composition of the present invention is well known to those skilled in the art.

[0059] The formula (g) of photosensitive composition described in table 5 embodiment 1-8

[0060]

[0061] In the above table, the corresponding specific components are:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com