Method for preparing agar oligosaccharide from immobilized agarase

A technology of agar oligosaccharides and agarase, which is applied in the direction of immobilization on or in the inorganic carrier, fermentation, etc., can solve the problems that the activity is easily affected by the environment, it is difficult to reuse and separate out, and achieve immobilization The method is simple and effective, the cost is low, and the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

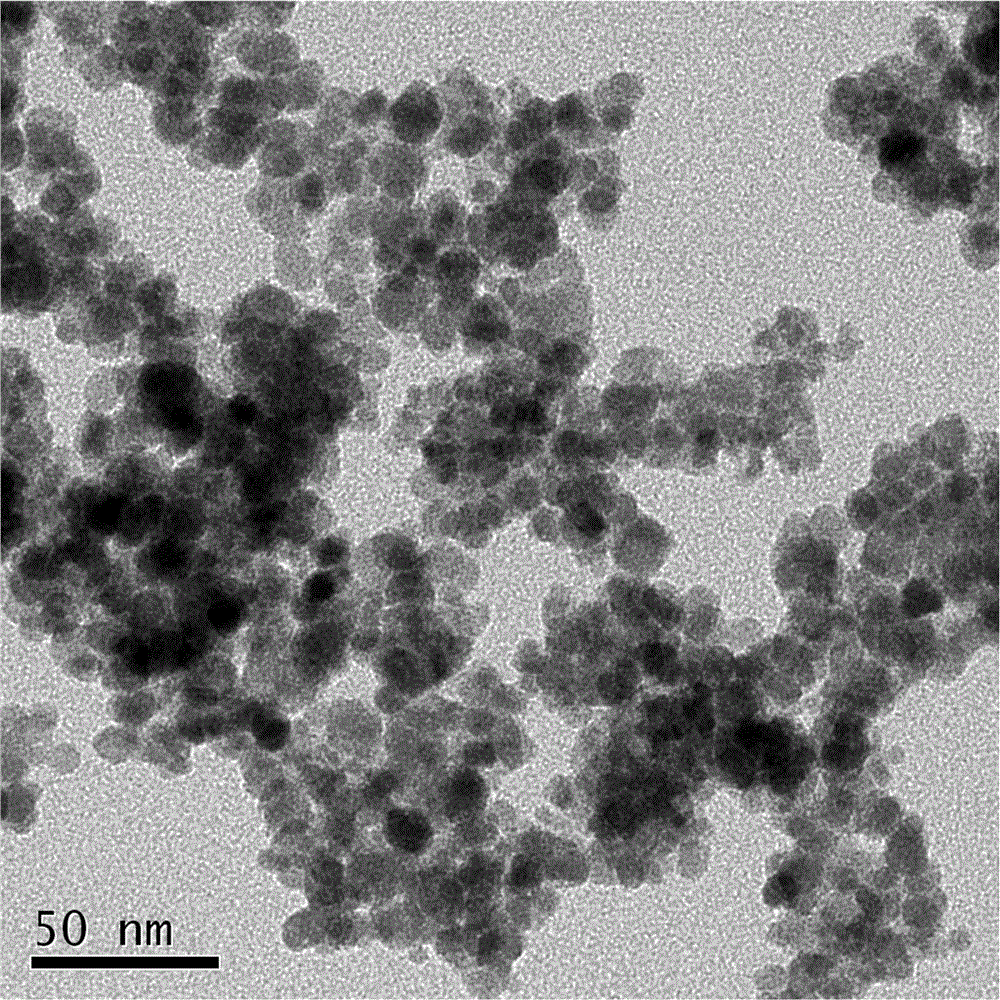

[0034] Example 1 Preparation of carboxyl functionalized magnetic carrier according to the present invention

[0035] Weigh 8.1g FeCl 3 ·6H 2 Dissolve O in a conical flask filled with 142.5 mL of deionized water, stir and heat to 70°C; weigh 4.4g of FeCl 2 4H 2 O was dissolved in 10 mL of deionized water, filtered, and 7.5 mL of the supernatant was added to the Erlenmeyer flask; under vigorous stirring conditions, 18 mL of concentrated ammonia water with a mass fraction of 25% was quickly added, and after 1 min of reaction, gradually Add 4.66 g of oleic acid dropwise, and stir vigorously at 70°C for 1 h; after the reaction, a black sol-like substance is obtained, and the obtained precipitate is separated from the reaction system by applying an external magnetic field; washed 2-3 times with alcohol to remove Excess oleic acid was washed with deionized water to neutral pH; 160 mL of KMnO at a concentration of 10 mg / mL was added 4 solution, ultrasonically oscillated for 8 h ...

Embodiment 2

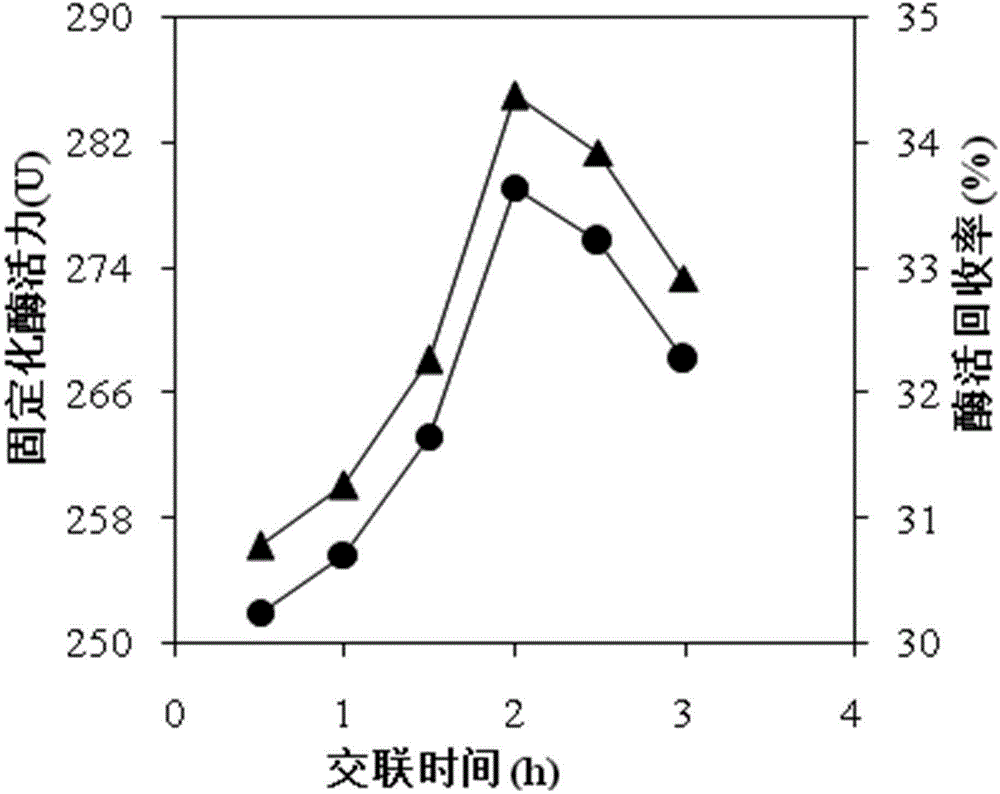

[0036] Example 2 The carboxyl functionalized magnetic Fe of the present invention 3 O 4 Optimization of Immobilization Conditions for Nanoparticle-immobilized Agarase

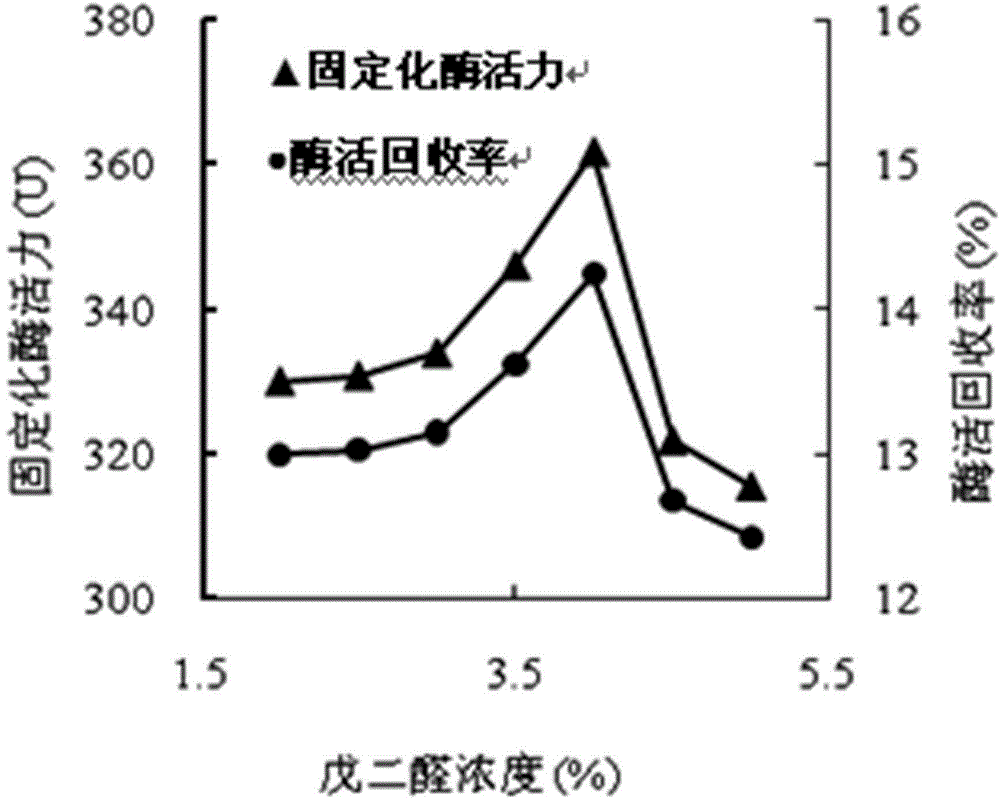

[0037] 1) Effect of glutaraldehyde concentration on agarase immobilization

[0038] The amount of immobilization carrier was 20 mg, the crosslinking time of glutaraldehyde was 3 h, the amount of enzyme added was 3 mL, the immobilization time was 3 h, and the immobilization temperature was 4°C. The influence of glutaraldehyde concentration on the immobilization of agarase was investigated. The maximum immobilized enzyme activity and enzyme activity recovery rate were obtained when the concentration of glutaraldehyde was 4%, which were 361.7 U and 14.2% respectively. The results are shown in figure 2 .

[0039] 2) The effect of the amount of enzyme added on the immobilization of agarase

[0040] The amount of immobilization carrier was 20 mg, the crosslinking time of glutaraldehyde was 3 h, the conc...

Embodiment 3

[0047] Example 3 The optimal reaction conditions for preparing agar oligosaccharides by immobilizing agarase on a carboxyl-functionalized magnetic carrier according to the present invention

[0048] 1) Optimum reaction temperature for immobilized agarase

[0049] In parallel, take 6 copies of 20 mg immobilized agarase in 50 mL Erlenmeyer flasks, add 10 mL of pH7.0 agar solution with a concentration of 0.2%, respectively, at 30°C, 35°C, 40°C, 45°C, 50°C , at 55°C for enzymatic hydrolysis. After the reaction, the optimum temperature of the immobilized enzyme was measured to be 40°C, the results are shown in Figure 7 .

[0050] 2) The optimal reaction pH of immobilized agarase

[0051] Take 6 copies of 20 mg immobilized agarase in parallel, and prepare agar solution with a concentration of 0.2% with buffer solutions of pH 5.5, pH 6.0, pH 6.5, pH 7.0, pH 7.5 and pH 8.0 respectively. Take out 10 mL of agar solution with different pH and add immobilized agarase for enzymatic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com