Culture medium and culture method for producing gentamicin by virtue of micromonospora fermentation

A fermentation medium and gentamicin technology, applied in the field of fermentation, can solve the problems of affecting the quality of fermentation broth and fermentation effect, high production cost of gentamicin, excess protein, etc., so as to improve the quality and the level of fermentation technology, The effect of improving the level of fermentation technology and lowering the cost of fermentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

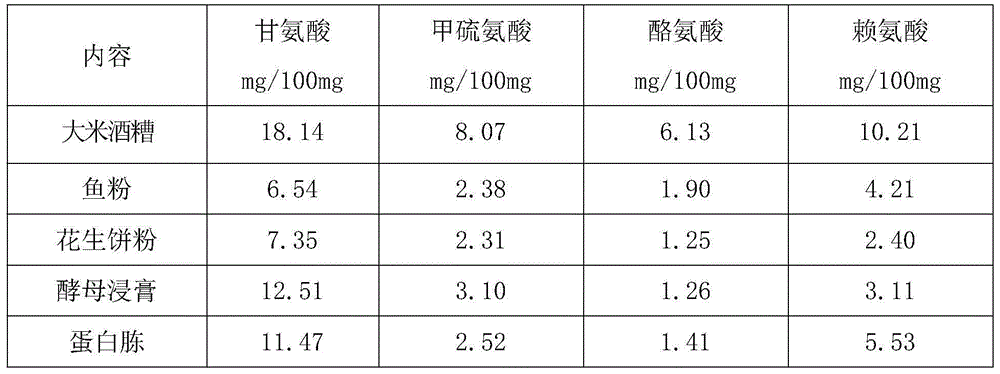

Method used

Image

Examples

Embodiment 1

[0063] primary seed culture

[0064] at 1m 3 Add 10L of maltose, 20kg of mixed starch, 1L of soybean oil, 25kg of low-temperature pressed soybean cake powder, 15kg of rice distiller's grains, 5kg of corn gluten powder, 2kg of light calcium carbonate, 1kg of ammonium sulfate, and 10g of maltase into the primary seed tank. Firstly, the primary seed culture medium is sterilized, cooled, and pressurized with sterile air, and then under flame protection, the cultured micromonospora mother bottle fermentation liquid is connected to the primary seed tank for cultivation, and the inoculum size is 0.5L. During the primary seed cultivation process, tank pressure is 0.04-0.08MPa; tank temperature is 34-37°C; air flow: 0-10h, 50m 3 / h; 6h~transplantation: 80m 3 / h; stirring speed 60r / min; pH7~8; culture time 50h. After the primary seed cultivation is completed, the cell concentration is 16%; the pH value is 7.1, and there is no other bacterial contamination.

[0065] secondary seed c...

Embodiment 2

[0071] primary seed culture

[0072] at 1m 3 Add 12L of maltose, 22kg of mixed starch, 2L of corn oil, 27kg of low-temperature pressed soybean cake powder, 16kg of rice distiller's grains, 6kg of corn gluten powder, 2.5kg of light calcium carbonate, 2kg of ammonium sulfate, and 15g of maltase into the primary seed tank. Firstly, the primary seed culture medium is sterilized, cooled, and pressurized with sterile air, and then under flame protection, the cultured micromonospora mother bottle fermentation liquid is connected to the primary seed tank for cultivation, and the inoculum size is 0.6L. During the primary seed cultivation process, tank pressure is 0.04-0.08MPa; tank temperature is 34-37°C; air flow: 0-10h, 52m 3 / h; 6h~transplantation: 85m 3 / h; stirring speed 70r / min; pH7~8; culture time 51h. After the primary seed cultivation is over, the cell concentration is 17%; the pH value is 7.3, and there is no other bacteria contamination.

[0073] secondary seed culture ...

Embodiment 3

[0079] primary seed culture

[0080] at 1m 3 Add 15L of maltose, 25kg of mixed starch, 3L of soybean oil, 30kg of low-temperature pressed soybean cake powder, 17kg of rice distiller's grains, 7kg of corn gluten powder, 3kg of light calcium carbonate, 3kg of ammonium sulfate, and 20g of maltase into the primary seed tank. First, sterilize the primary seed culture medium, cool it, and keep the pressure with sterile air, and then, under flame protection, transfer the cultured Micromonospora mother bottle fermentation liquid into the primary seed tank for cultivation, and the inoculum size is 0.7L. During the primary seed cultivation process, tank pressure is 0.04-0.08MPa; tank temperature is 34-37°C; air flow: 0-10h, 55m 3 / h; 6h~transplantation: 90m 3 / h; stirring speed 80r / min; pH7~8; culture time 52h. After the primary seed cultivation is completed, the cell concentration is 20%; the pH value is 7.5, and there is no other bacterial contamination.

[0081] secondary seed c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com