Method for separating and recovering scandium in stable zirconia ceramic wastes containing scandium and rare earth

A technology of separation and recovery of zirconia ceramics, applied in the direction of improving process efficiency, etc., can solve the problems of low purity of recovered products, distribution and precipitation, large energy consumption, etc., and achieve high industrial use value, low recycling cost, and less waste water discharge Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

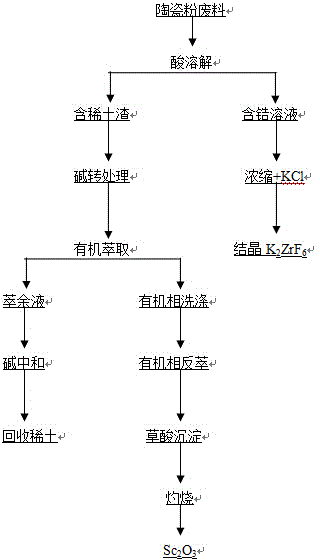

Method used

Image

Examples

Embodiment 1

[0031] Take 100 g of solid fuel cell (SOFC) ceramic waste, chemically composed of ZrO-containing 2 91%, Sc 2 o 3 7%, CeO 2 1.2%, Y 2 o 3 0.3% as raw material, first crush the above-mentioned waste to below 200 mesh, put it into a plastic king cup, add 500ml, 30%HF, soak at room temperature overnight, filter 610ml of filtrate, containing 141g / l ZrO2, the solution is heated and concentrated to When the volume is 280ml, add 100g solid KCl, stir evenly, cool, crystals are precipitated, and 190g KCl is obtained after draining 2 ZrF 6 , the recovery rate of zirconium is >90%, and the mother liquor is reserved for the next cycle.

[0032] ② After washing 87g of filter residue dissolved in HF, add 30ml of 8% NaOH solution, heat to temperature T=80°C, keep warm for 0.5 hours, cool and filter to obtain 12.45g of residue, wash the residue twice, add 10% 100ml of HCl, dissolve the slag, and obtain 2 o 3 62g / l, CeO 2 10g / l, Y 2 o 3 110ml of 2.6g / l solution, its acidity i...

Embodiment 2

[0037] Chemical composition is the ceramic powder waste material 100g with the embodiment 1, at first waste material is pulverized to below 200 orders, puts into plastic king cup, adds mixed acid (10%HF+5%H 2 SO 4 ) 600ml, heated to 80°C for 2 hours, cooled and filtered, the filtrate was heated, concentrated and crystallized as in Example 1, and the slag was washed with water, and the recovery and treatment steps of scandium and rare earth were the same as in Example 1.

Embodiment 3

[0039] Oxygen sensor zirconium-containing ceramic waste with a chemical composition of 92% ZrO 2 %, 8%Y 2 o 3 , first crush the waste to below -200 mesh, put it into a plastic bucket, add 20% HF, heat to temperature T=60°C, keep warm for 3hr, cool and filter, filtrate recovery, zirconium separation method is the same as in Example 1, filter After the residue is washed with water, use 10% NaOH solution at a temperature of 70°C, residue / liquid=1 / 2, conversion treatment time 1hr, cool and filter, wash the filter residue twice with water, dissolve HCl, control pH=1, add oxalic acid Precipitate yttrium. After the precipitate was washed, it was burned at 900°C for 3 hours to obtain yttrium oxide with a purity greater than 99%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com