Food-grade thermoplastic composite material as well as preparation method and application thereof

A composite material, food-grade technology, applied in the field of food-grade thermoplastic materials and their preparation, can solve the problems of easy moldy bamboo and wood drawers, heavy bamboo steamers, heavy steamers, etc., to improve surface finish, dimensional stability, and excellent mechanical properties. Performance and heat resistance, the effect of improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

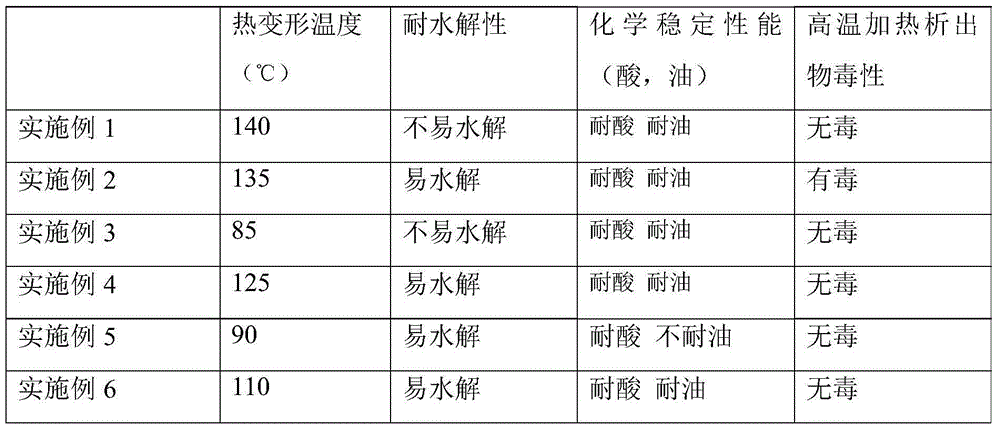

Embodiment 1

[0034] (1) Food-grade filler treatment: Dry the used food-grade filler at 100-110 degrees to remove moisture, and then pass the dried food-grade filler through a mesh sieve to obtain a food-grade filler with a particle size of 20-200nm;

[0035] (2) Mix 5 parts of food-grade calcium carbonate, 20 parts of food-grade calcium sulfate whisker, and 1.2 parts of food-grade calcium stearate in a blender for 3 to 5 minutes to obtain food coated with calcium stearate Grade calcium carbonate powder and calcium sulfate whiskers;

[0036] (3) Mix 100 parts of food-grade polypropylene, 0.2 parts of titanium dioxide and the mixture in step (1) in a high-speed mixer for 2 to 3 minutes; add the obtained mixture into a twin-screw extruder for mixing, and the extrusion temperature is 200 ~235°C, of which the first zone is 200-215°C, the second zone is 215-235°C, the third zone is 215-235°C, the fourth zone is 210-230°C; the screw speed of the twin-screw extruder is 300-350r / min; the obtained...

Embodiment 2

[0038] (1) Food-grade filler treatment: Dry the used food-grade filler at 100-110 degrees to remove moisture, and then pass the dried food-grade filler through a mesh sieve to obtain a food-grade filler with a particle size of 20-200nm;

[0039] (2) Mix 8 parts of food-grade calcium carbonate, 17 parts of calcium sulfate whiskers and 1 part of food-grade paraffin in a blender for 3-5 minutes to obtain food-grade calcium carbonate powder and calcium sulfate whiskers coated with paraffin;

[0040] (3) Mix 100 parts of food-grade polycarbonate, 0.1 part of food-grade tartrazine pigment and the mixture in step (1) in a high-speed mixer for 2 to 3 minutes; add the obtained mixture into a twin-screw extruder for mixing, The extrusion temperature is 220-300°C, of which the first zone is 220-230°C, the second zone is 250-280°C, the third zone is 260-300°C, and the fourth zone is 255-290°C; the screw speed of the twin-screw extruder is 330-380r / min; the obtained material was extrude...

Embodiment 3

[0042] (1) Food-grade filler treatment: Dry the used food-grade filler at 100-110 degrees to remove moisture, and then pass the dried food-grade filler through a mesh sieve to obtain a food-grade filler with a particle size of 20-200nm;

[0043] (2) Put 9 parts of food-grade medical-grade talc powder, 25 parts of calcium sulfate whiskers, and 1.5 parts of food-grade hydrocarbon wax in a blender and mix for 3-5 minutes to obtain medical-grade talc powder and calcium sulfate coated with hydrocarbon wax on the surface Whiskers;

[0044] (3) Mix 100 parts of food-grade high-temperature-resistant polyethylene, 0.2 parts of food-grade yellow pigment and the mixture in step (1) in a high-speed mixer for 2 to 3 minutes; add the obtained mixture into a twin-screw extruder for mixing , the extrusion temperature is 150-240°C, of which the first zone is 150-170°C, the second zone is 180-220°C, the third zone is 190-240°C, and the fourth zone is 180-230°C; the screw speed of the twin-scr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Heat distortion temperature | aaaaa | aaaaa |

| Heat distortion temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com