Method for performing palladium-free activation electroless copper plating on basalt fiber

A basalt fiber and chemical copper plating technology is applied in the field of palladium-free activated chemical copper plating on basalt fibers, which can solve the problem of high cost of raw materials, and achieve the effects of high production efficiency, easy mass production and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The microstructure and performance of the conductive basalt fabric are as follows:

[0034] 1. Surface morphology of conductive copper-plated basalt fabric:

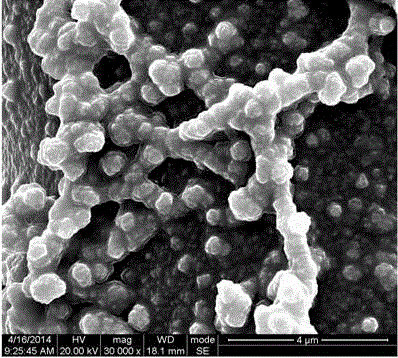

[0035] SEM photos of electroless copper-plated basalt fabrics at different magnifications are shown in figure 1 and 2 . It can be seen from the figure that the surface of the basalt fiber is completely covered by copper particles, and the copper particles are uniformly plated on the surface of the fabric. Judging from the SEM with a magnification of 30000, the copper particles have clustered, and the particle size after clustering is that the copper nanoparticles are spherical, the particle size is about 60-100nm, and the particle size distribution is uniform.

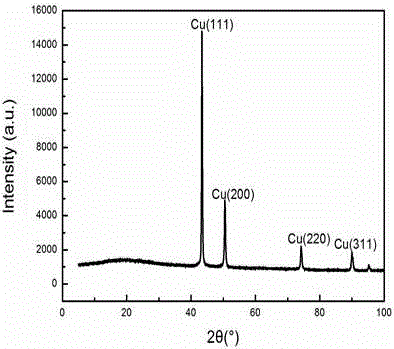

[0036] 2. Crystal structure of conductive copper-coated basalt fabric:

[0037] Crystal structure of electroless copper plating on basalt fabric see image 3 . According to the X-ray diffraction standard card PDF, it can be determined from the diffr...

Embodiment 2

[0043] The microstructure and performance of the conductive basalt fabric are as follows:

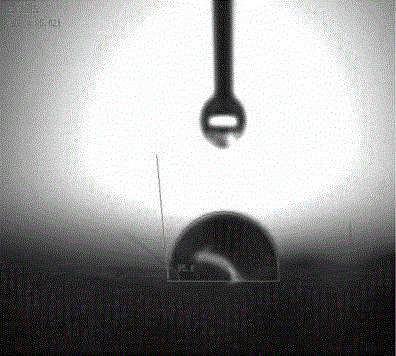

[0044] 1. Contact angle of basalt fabric after NaOH pretreatment:

[0045] The contact angles of basalt fabrics before and after NaOH etching treatment are shown in Figure 4 and 5 , it can be seen from the figure that the contact angle of the original basalt fabric is 95.62°, and the contact angle of the basalt fabric after etching is 39.86°. Facilitates the deposition of nickel on the surface of the fabric.

[0046] 2. Surface morphology of conductive copper-plated basalt fiber fabric:

[0047] The scanning electron micrographs at different magnifications of the electroless copper-plated basalt fabric etched by 40g / l NaOH are shown in Figure 6 and 7 . It can be seen from the figure that the surface of the basalt fabric is completely covered by copper particles, and the copper particles are evenly plated on the surface of the fabric. From the SEM with a magnification of 30000, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com