A flexible and transparent gas sensor based on semiconducting single-walled carbon nanotubes

A technology of single-walled carbon nanotubes and gas sensors, which is applied in the field of flexible and transparent gas sensors, can solve the problems of consuming a large amount of energy, and achieve the effects of high detection sensitivity, fast response speed, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

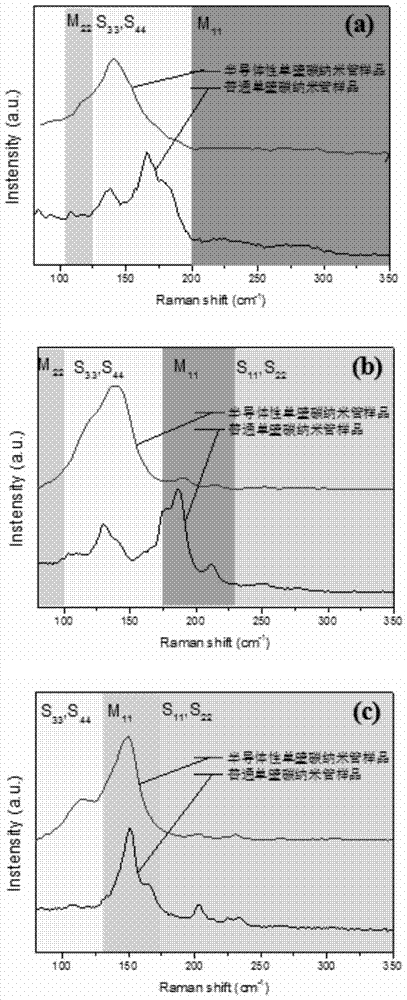

[0033] Preparation of semiconducting single-walled carbon nanotubes: ferrocene containing sulfur powder (the sulfur powder and ferrocene are evenly mixed, the weight ratio is 1:200) pressed into blocks and placed in a chemical vapor deposition reaction furnace (the diameter of the furnace tube is 50mm, the length of the constant temperature zone is 10cm), in a hydrogen atmosphere, the temperature rises to 1100°C at a rate of 22°C / min, and 30ml / min of methane and 2000ml / min of hydrogen are introduced, and the ferrocene block is pushed To the position where the furnace temperature is 80° C., the growth of single-walled carbon nanotubes is carried out. After the growth of carbon nanotubes, turn off the methane and use 400ml / min hydrogen as the protective gas to allow the reaction furnace to cool down to room temperature naturally. Samples were collected and characterized by multi-wavelength Raman. The Raman spectrum is as follows figure 1 (a)- figure 1(c) shown. Multi-waveleng...

Embodiment 2

[0037] Preparation of semiconducting single-walled carbon nanotubes: same as in Example 1.

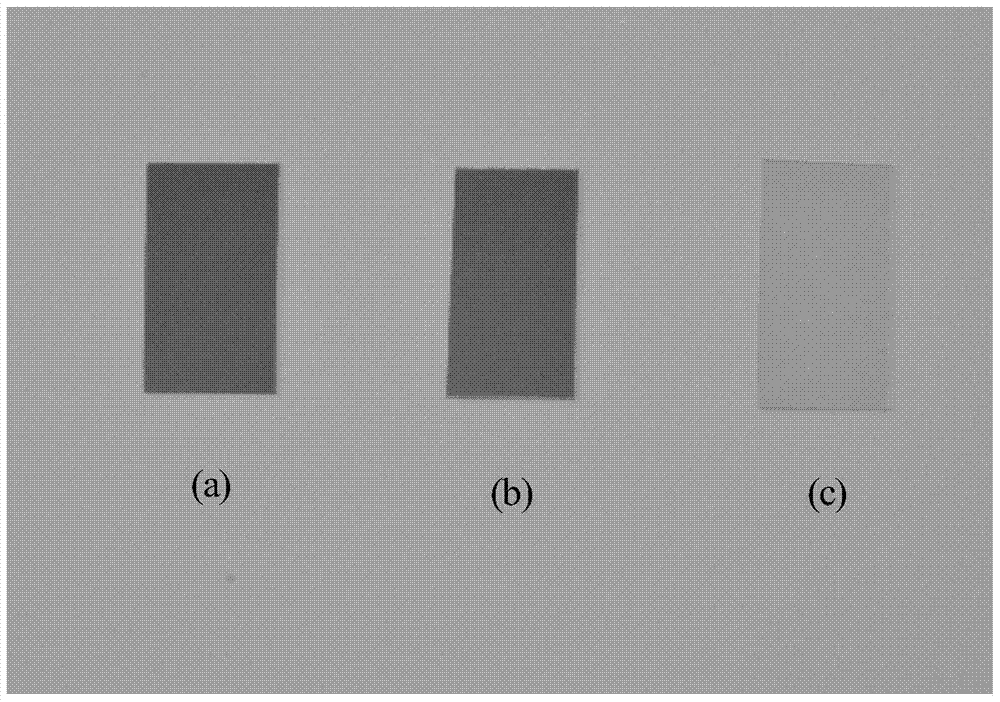

[0038] Dry transfer preparation of semiconductive single-walled carbon nanotube film: same as in Example 1, this control deposition time is 4min, and the light transmittance of the obtained semiconductive single-walled carbon nanotube film is 90%, such as image 3 as shown in c.

[0039] Construction and performance of a flexible, transparent, and bendable gas sensor: the manufacturing steps are the same as in Example 1. The sensitivity of the gas sensor to ammonia is 25%, and the response time is 1s.

Embodiment 3

[0041] Preparation of semiconducting single-walled carbon nanotubes: same as in Example 1.

[0042] Wet preparation of semiconductor single-walled carbon nanotube films: the collected carbon nanotube samples are oxidized in air to remove impurities such as amorphous carbon, treated with hydrochloric acid to remove metal catalyst impurities, and rinsed with deionized water to medium sex. Dissolve the cleaned carbon nanotubes in an aqueous solution of 1wt% sodium dodecylbenzenesulfonate (SDBS) or sodium dodecyl sulfate (SDS), and perform TIP ultrasonication for 30 minutes in the mode of ultrasonic 1s, off 1s , then with 13000r / min centrifugal 30~60min, get the supernatant and spray on the PET film, obtain the semiconductive single-walled carbon nanotube-PET composite film that light transmittance is 55% (film thickness) such as image 3 as shown in b.

[0043] Construction and performance of a flexible, transparent, and bendable gas sensor: the manufacturing steps are the same...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com