Preparation method for solar battery materials with three-zone gap tin doped with copper, gallium and sulphur

A solar cell, tin doping technology, applied in the fields of nanotechnology, chemical instruments and methods, tin compounds, etc. for materials and surface science, can solve the problems of tin doping copper gallium sulfur without intermediate band gap, and avoid the Adverse effects, enhanced absorption, excellent potential effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The solvothermal preparation steps of tin-doped copper-gallium-sulfur triple-bandgap solar cell materials are as follows:

[0037] (1) Dissolve the copper chloride of 0.8mmol in 40ml ethylene glycol solution, stir evenly and make it fully dissolve;

[0038] (2) Add 2mmol thiourea again, stir evenly to make it fully dissolve;

[0039] (3) Add 0.8 mmol of gallium chloride again, and stir evenly to make it fully dissolve;

[0040] (4) Add 0.04mmol tin tetrachloride again, stir to obtain a uniform reaction solution system;

[0041] (5) Transfer the reaction solution system to a 50ml polytetrafluoroethylene-lined reaction kettle, keep the temperature at 220° C. for 12 hours, and cool naturally to obtain a solvothermal product;

[0042] (6) The obtained solid product was dried in a vacuum oven at 80° C. for 6 hours to obtain the final product.

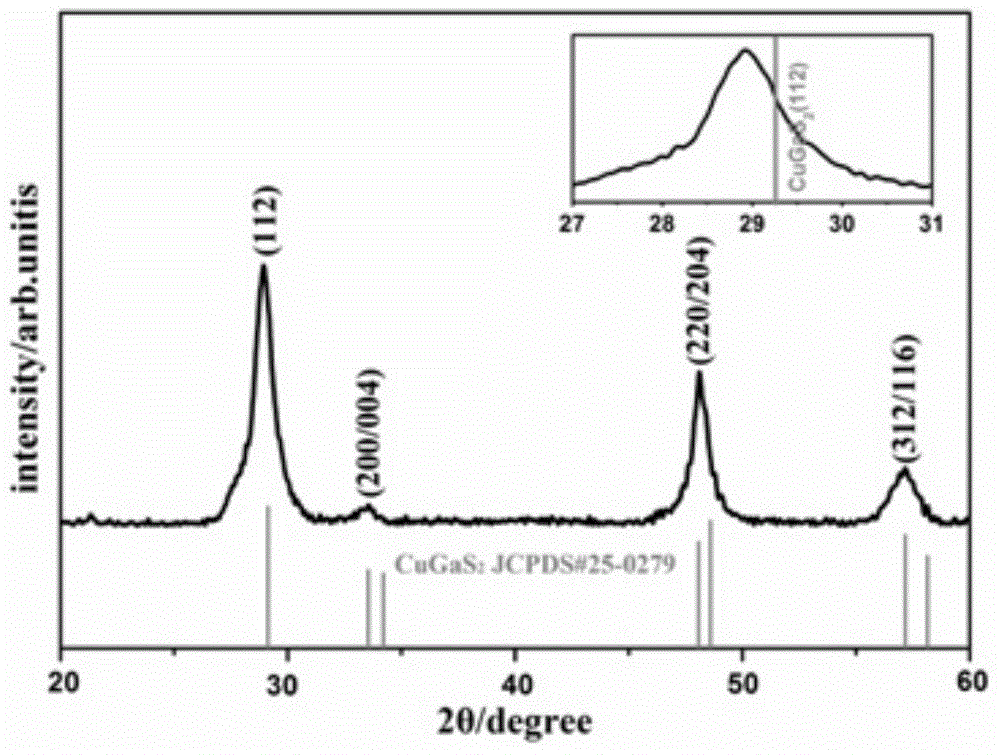

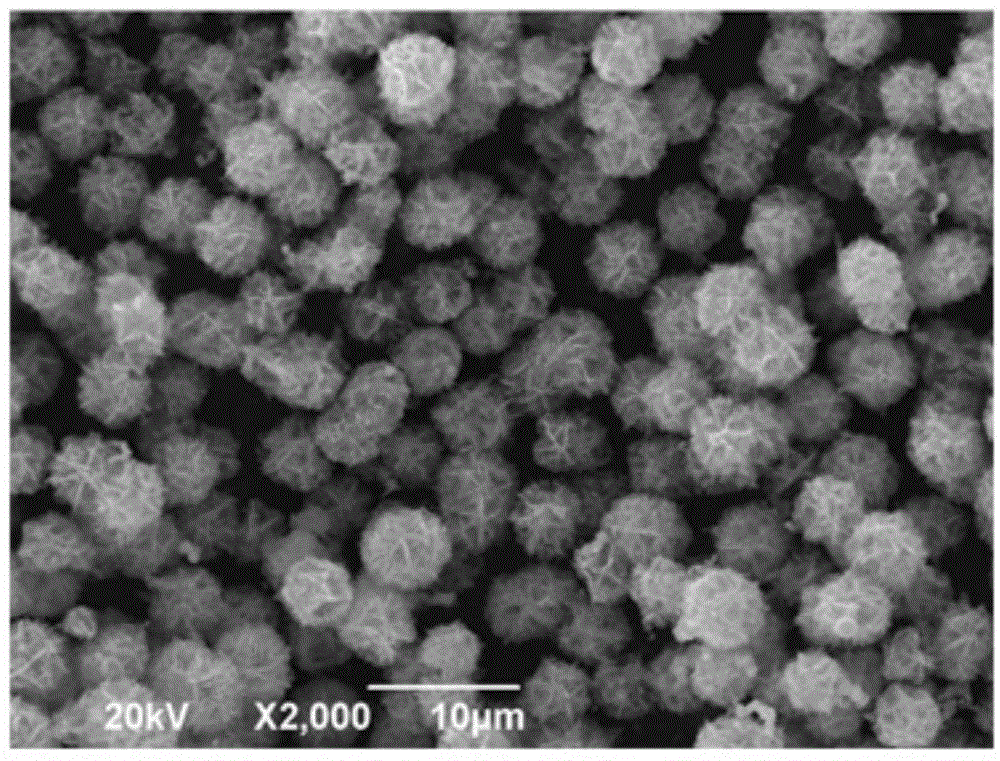

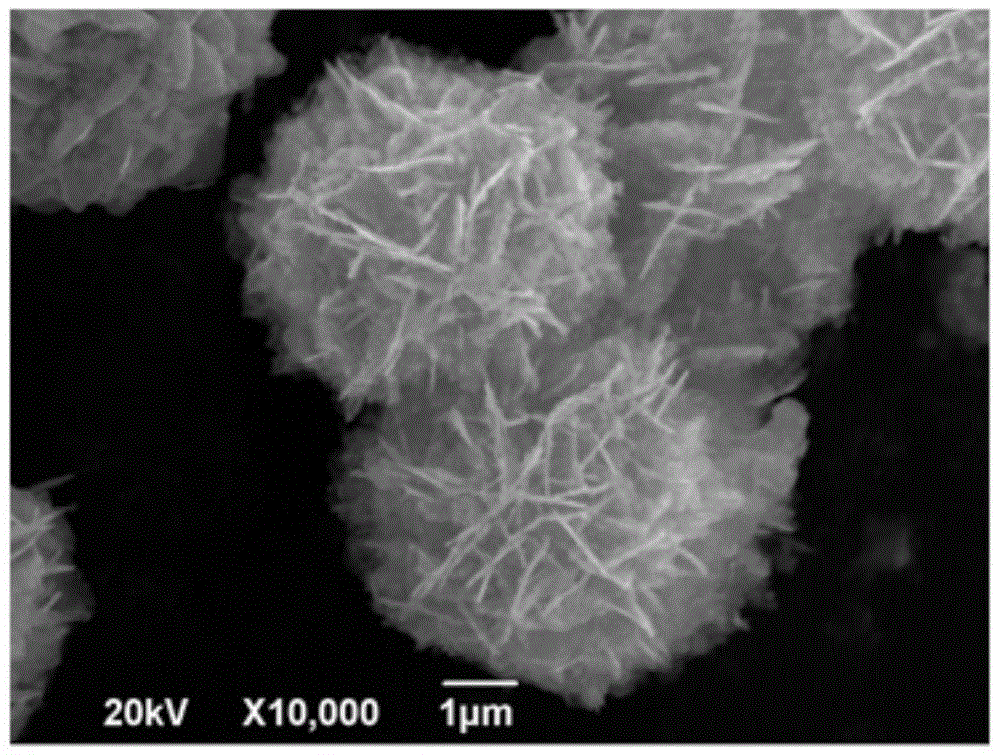

[0043] The XRD spectrum and partial enlarged view of the tin-doped copper-gallium sulfur flower-shaped microsphere product obtain...

Embodiment 2

[0053] The solvothermal preparation steps of tin-doped copper-gallium-sulfur triple-bandgap solar cell materials are as follows:

[0054] (1) Dissolve 0.8mmol of copper chloride in 40ml of ethylene glycol solution, stir evenly to make it fully dissolved; (2) add 1.6mmol thiourea again, stir evenly to make it fully dissolve;

[0055] (3) Add 0.8 mmol of gallium chloride again, and stir evenly to make it fully dissolve;

[0056] (4) Add 0.04mmol tin tetrachloride again, stir to obtain a uniform reaction solution system;

[0057] (5) Transfer the reaction solution system to a 50ml polytetrafluoroethylene-lined reaction kettle, keep the temperature at 220° C. for 12 hours, and cool naturally to obtain a solvothermal product;

[0058] (6) The obtained solid product was dried in a vacuum oven at 80° C. for 6 hours to obtain the final product.

Embodiment 3

[0060] The solvothermal preparation steps of tin-doped copper-gallium-sulfur triple-bandgap solar cell materials are as follows:

[0061] (1) Dissolve the copper chloride of 0.8mmol in 40ml ethylene glycol solution, stir evenly and make it fully dissolve;

[0062] (2) Add 2mmol thiourea again, stir evenly to make it fully dissolve;

[0063] (3) Add 0.8 mmol of gallium chloride again, and stir evenly to make it fully dissolve;

[0064] (4) Add 0.04mmol tin tetrachloride again, stir to obtain a uniform reaction solution system;

[0065] (5) Transfer the reaction solution system to a 50ml polytetrafluoroethylene-lined reaction kettle, keep the temperature at 210°C for 12h, and cool naturally to obtain a solvothermal product;

[0066] (6) The obtained solid product was dried in a vacuum oven at 80° C. for 6 hours to obtain the final product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com