A method for producing lactic acid from bagasse

A sugarcane bagasse and lactic acid technology, applied in microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of high cost, aggravate grain and feed resources, consume large grains, etc., and achieve low cellulose loss and increase. Biotransformation efficiency, reducing the effect of ineffective adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

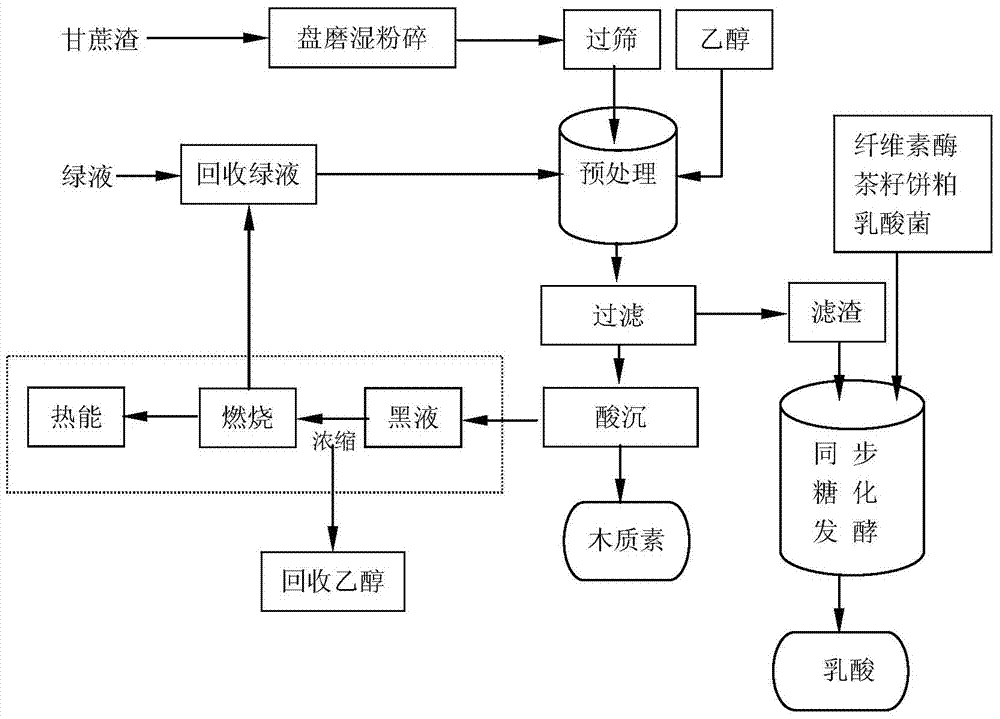

[0023] The present embodiment provides a kind of method of producing lactic acid by bagasse, specifically:

[0024] The bagasse is pulverized by adding water to a disk mill, and sieved by an industrial vibrating sieve through a 20-mesh sieve. The pretreatment process is carried out in a pressure-resistant reactor, the mass percentage of bagasse is 10% (w / v), and the reaction is heated at 145° C. for 3 hours. Ethanol: water: 1:1 (V / V), green liquid (sodium carbonate is 75.2g / L, sodium hydroxide is 23.0g / L, iron ion is 1.14g / L, calcium ion is 0.39g / L, pH13. 3. Taken from a paper mill in Shandong) dosage: 1.5ml / (g substrate). Filtration is performed after pretreatment, and the filtrate is separated by acid precipitation to separate lignin, then concentrated to recover ethanol, and the residue is burned to recover heat energy and green liquor. The solid filter residue directly enters the synchronous saccharification and fermentation to produce lactic acid. Add 50 g of pretreate...

Embodiment 2

[0027] The present embodiment provides a kind of method of producing lactic acid by bagasse, specifically:

[0028] The bagasse is pulverized by adding water to a disk mill, and sieved by an industrial vibrating sieve through a 20-mesh sieve. The pretreatment process is carried out in a pressure-resistant reactor, the mass percentage of bagasse is 10% (w / v), and the reaction is heated at 140° C. for 2 hours. Ethanol: water: 1:1 (V / V), the amount of green solution: 0.5ml / (g substrate). Filtration is performed after pretreatment, and the filtrate is separated by acid precipitation to separate lignin, then concentrated to recover ethanol, and the residue is burned to recover heat energy and green liquor. The solid filter residue directly enters the synchronous saccharification and fermentation to produce lactic acid. Add 50 g of pretreated bagasse and 5 g of tea seed cake to 1 liter of fermentation system, and use 10% NaOH or 10% H 2 SO 4 The solution adjusted the pH of the s...

Embodiment 3

[0030] The present embodiment provides a kind of method of producing lactic acid by bagasse, specifically:

[0031] The bagasse is pulverized by adding water to a disk mill, and sieved by an industrial vibrating sieve through a 20-mesh sieve. The pretreatment process is carried out in a pressure-resistant reactor, the mass percentage of bagasse is 10% (w / v), and the reaction is heated at 140° C. for 4 hours. Ethanol: water ratio: 1:1 (V / V), green solution dosage: 1.0ml / (g substrate). Filtration is performed after pretreatment, and the filtrate is separated by acid precipitation to separate lignin, then concentrated to recover ethanol, and the residue is burned to recover heat energy and green liquor. The solid filter residue directly enters the synchronous saccharification and fermentation to produce lactic acid. Add 50 g of pretreated bagasse and 5 g of tea seed cake to 1 liter of fermentation system, and use 10% NaOH or 10% H 2 SO 4 The solution adjusted the pH of the sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com