Method for preparing orderly micro-nano structure on titanium substrate surface

A micro-nano structure, titanium matrix technology, applied in prosthesis, medical science and other directions, can solve problems such as no research reports, surface wear debris, inflammation, etc., to eliminate randomness, easy integration, and slow down bone resorption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Select pure titanium samples (total surface area is about 2000mm 2 ) followed by conventional grinding, physical polishing and chemical polishing:

[0031] Physical polishing: Grinding 3 times, the number of sandpaper meshes is 800, 1000 and 1500 in turn.

[0032] Chemical polishing: use 200ml of aqueous solution containing 3wt% HF and 0.02wt‰ potassium perfluorooctane sulfonate as the polishing solution, and the polishing time is 2 minutes, then use acetone, ethanol and deionized water to immerse in ultrasonic cleaning for 3 minutes, and dry;

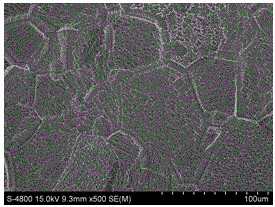

[0033] (2) Acid etching: The polished pure titanium sample was placed in 200ml aqueous solution containing 66wt% concentrated sulfuric acid, and immersed at 80°C for 5min. Then at room temperature, use acetone, ethanol and deionized water to ultrasonically clean in turn, acetone for 1 minute, ethanol and deionized water for 2 minutes each, after drying, observe the surface image under a field emission scanning electron micr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com