A kind of polyphosphorus ferric sulfate flocculant and its preparation method and application

A polyphosphorus ferric sulfate and flocculant technology, applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, phosphorus compounds, etc., can solve problems such as unsuitable water treatment applications, increased production costs, environmental pollution, etc. The flocculation effect will not be weakened, the reaction speed is fast, and the use is convenient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

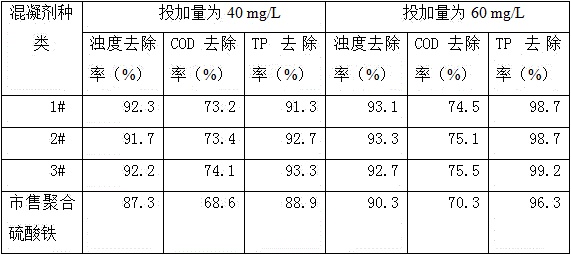

Examples

Embodiment 1

[0021] Embodiment 1: a kind of preparation method of polyphosphorus ferric sulfate flocculant:

[0022] 1) Weigh 55.6 g of ferrous sulfate heptahydrate and place it in a beaker, add 30 mL of industrial sulfuric acid with a mass concentration of 20%, stir at room temperature for 10 min at a stirring speed of 60 r / min, and carry out acidification and dissolution;

[0023] 2) After step 1) is dissolved, add 14 mL of hydrogen peroxide with a mass concentration of 30% at a rate of 1 mL / min under continuous stirring to fully oxidize, insert the thin tube into the bottom of the beaker, and continue stirring for 10 minutes after the addition is complete. min, forming a uniform reddish-brown liquid;

[0024] 3) Weigh 9.36 g of sodium dihydrogen phosphate, add it to the liquid prepared in step 2) at a slow speed, stir to dissolve and polymerize for 20 minutes, and continue to stir;

[0025] 4) After the solution 3) is stirred evenly, add NaHCO under stirring condition 3 Solid 5.04 g, ...

Embodiment 2

[0030] Embodiment 2: a kind of preparation method of polyphosphorus ferric sulfate flocculant:

[0031] 1) Weigh 55.6 g of ferrous sulfate heptahydrate and place it in a beaker, add 27 mL of industrial sulfuric acid with a mass concentration of 25%, stir at room temperature for 15 min at a stirring speed of 65 r / min, and carry out acidification and dissolution;

[0032] 2) After the dissolution in step 1) is completed, add 12 mL of hydrogen peroxide with a mass concentration of 35% at a rate of 1.5 mL / min under continuous stirring to fully oxidize, insert the thin tube into the bottom of the beaker, and continue stirring for 15 min after the addition is complete , forming a uniform reddish-brown liquid;

[0033] 3) Weigh 9.36 g of sodium dihydrogen phosphate, add it into the liquid prepared in step 2) at a slow speed, stir to dissolve and polymerize for 25 minutes, and continue to stir;

[0034] 4) After the solution 3) is stirred evenly, add NaHCO under stirring condition 3 S...

Embodiment 3

[0038] Embodiment 3: a kind of preparation method of polyphosphorus ferric sulfate flocculant:

[0039] 1) Weigh 55.6 g of ferrous sulfate heptahydrate and place it in a beaker, add 22 mL of industrial sulfuric acid with a mass concentration of 30%, stir at room temperature for 20 min at a stirring speed of 70 r / min, and carry out acidification and dissolution;

[0040] 2) After step 1) is dissolved, add 20 mL of hydrogen peroxide with a mass concentration of 30% at a rate of 1 mL / min to fully oxidize while continuing to stir, insert a thin tube into the bottom of the beaker, and continue stirring for 10 min after the addition is complete , forming a uniform reddish-brown liquid;

[0041] 3) Weigh 9.36 g of sodium dihydrogen phosphate, add it to the liquid prepared in step 2) at a slow speed, stir to dissolve and polymerize for 20 minutes, and continue to stir;

[0042] 4) After the solution 3) is stirred evenly, add NaHCO under stirring condition 3 Solid 5.04 g, adding spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com