Preparation method of pentaerythritol double ring dimethyl silicate compound serving as fire retardant

A technology of dimethyl silicate and pentaerythritol, which is applied in chemical instruments and methods, compounds of Group 4/14 elements of the periodic table, organic chemistry, etc., can solve problems such as secondary hazards, and achieve low cost and compatibility. The effect of good performance and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

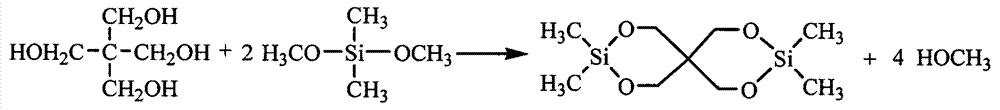

[0020] Example 1 In a 150ml four-necked flask equipped with a stirrer, a thermometer, and a high-efficiency fractionation device, add 13.62g (0.1mol) pentaerythritol, 24.04g (0.2mol) dimethyldimethoxysilane and 40ml toluene, and heat up to Start the boiling fractionation reaction at 80°C, control the temperature at the top of the fractionation column to not be higher than 65°C, and continuously separate the generated methanol. As the reaction progresses, the free dimethyldimethoxysilane decreases, and the temperature of the reaction system gradually increases. Insulate and react at 110°C for about 7 hours. When the fractionated methanol reaches the theoretical amount, stop the reaction, cool, filter with suction, rinse the filter cake with water three times, drain it, and dry the filter cake to obtain a white solid pentaerythritol bicyclodimethylsilane Ester, product yield 95.0%.

Embodiment 2

[0021] Example 2 In a 150ml four-neck flask equipped with a stirrer, a thermometer, and a high-efficiency fractionation device, add 13.62g (0.1mol) of pentaerythritol, 24.04g (0.2mol) of dimethyldimethoxysilane and 50ml of dimethylbenzene, and heat up Start the boiling fractionation reaction at 80°C, control the top temperature of the fractionation column to not be higher than 65°C, and continuously separate the generated methanol. As the reaction progresses, the free dimethyldimethoxysilane decreases, and the temperature of the reaction system gradually increases , keep the reaction at 140°C for about 6 hours, when the fractionated methanol reaches the theoretical amount, stop the reaction, cool, filter with suction, rinse the filter cake with water three times, drain it, and dry the filter cake to obtain a white solid pentaerythritol bicyclodimethyl Silicate, product yield 98.5%.

Embodiment 3

[0022] Example 3 In a 150ml four-neck flask equipped with a stirrer, a thermometer, and a high-efficiency fractionation device, add 13.62g (0.1mol) of pentaerythritol, 24.04g (0.2mol) of dimethyldimethoxysilane and 50ml of tetrachloroethane , the temperature is raised to 80°C to start the boiling fractionation reaction, and the temperature at the top of the fractionation column is controlled not to be higher than 65°C, and the generated methanol is continuously separated. As the reaction progresses, the free dimethyldimethoxysilane decreases, and the temperature of the reaction system gradually Raise the temperature and keep it warm at 130°C for about 7 hours. When the fractionated methanol reaches the theoretical amount, stop the reaction, cool, filter with suction, rinse the filter cake with water three times, drain it, and dry the filter cake to obtain a white solid pentaerythritol bicyclodi Methyl silicate, product yield 96.6%.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap