Method for preparing metal-organic framework material film

A metal-organic framework, material thin film technology, applied in the fields of organic chemistry, chemical instruments and methods, compounds of elements of Group 4/14 of the periodic table, etc. Difficulties, complex molding methods, etc., to achieve the effects of good processing performance, mild conditions, and fast polymerization speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1)UiO-66-NH 2 preparation of

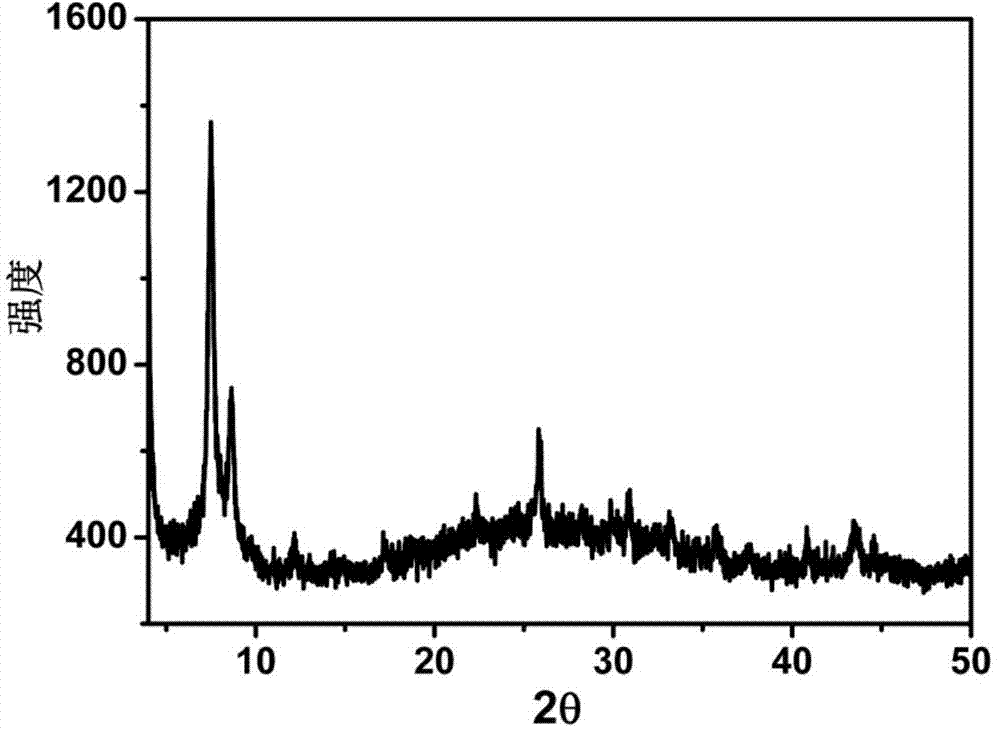

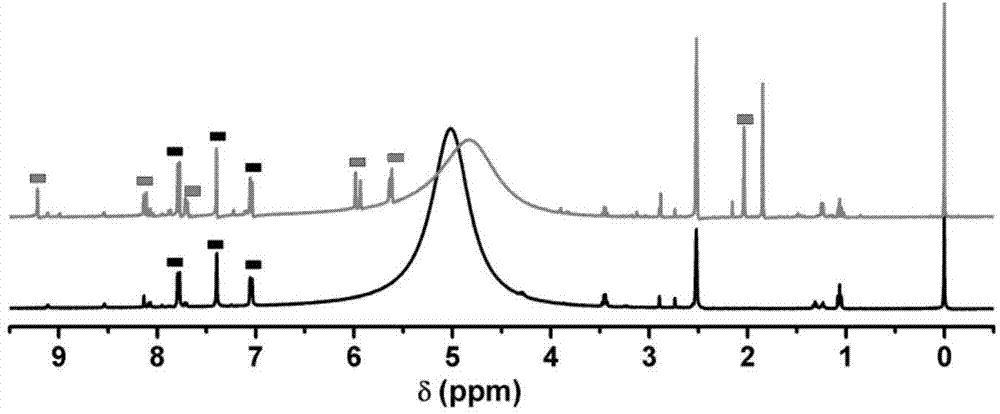

[0044] 268mg (1.5mmol) of ZrCl 4 (predissolved in 12mL of N,N-dimethylformamide (DMF) and hydrochloric acid in a mixed solvent with a volume ratio of 5:1) and 250mg (1.08mmol) of 2-aminoterephthalic acid (predissolved in 20mL of DMF ) mixed evenly, reacted at 80°C for 12h, centrifuged, washed with excess DMF to obtain powder 1, powder 1 was soaked in ethanol for 3 days (new solvent was changed every day), centrifuged to obtain powder 2, powder 2 was vacuum Dry at 150°C for 12 hours under ambient conditions to obtain a yellow powdery solid. Obtain its diffraction spectrum by X-ray powder diffractometer, such as figure 1 , and the UiO-66-NH 2 The diffraction pattern matches well, indicating that the pure phase UiO-66-NH 2 .

[0045] (2)PSM UiO-66-NH 2 Preparation of (UiO-66-NH 2 post-synthetic modification of

[0046] 57.2 mg of UiO-66-NH 2 Disperse in 2mL of dichloromethane, add 77mg of methacrylic anhydride, react at room temper...

Embodiment 2

[0050] (1) UiO-66-NH 2 preparation of

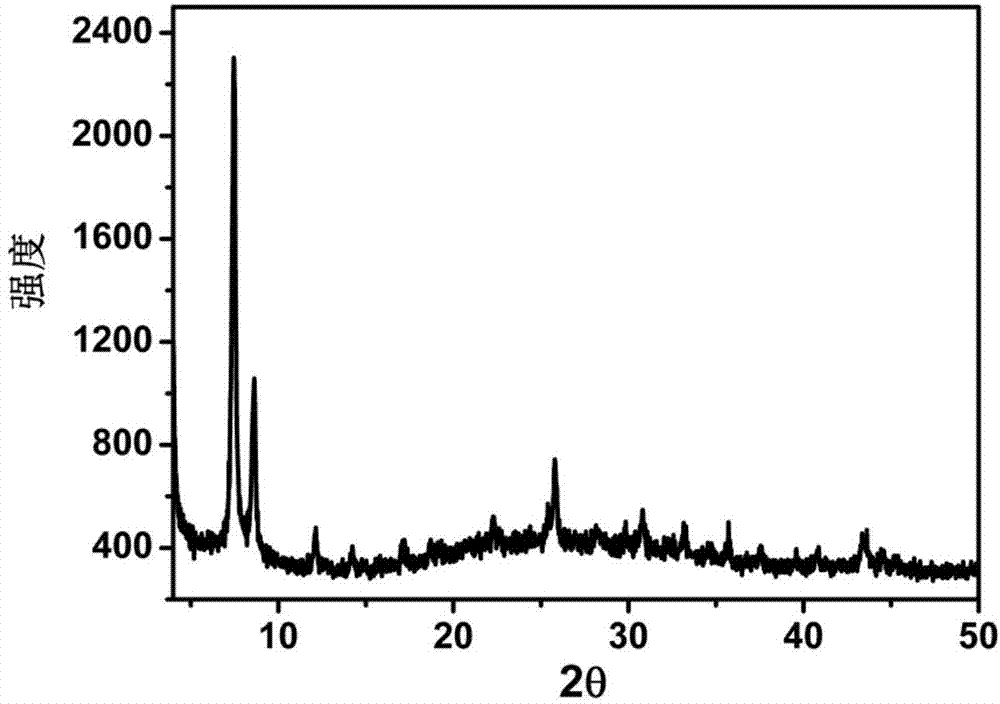

[0051] Prepare UiO-66-NH according to the method of Example 1 step (1) 2 . The difference is: the immersion time in ethanol is 4 days.

[0052] (2)PSM UiO-66-NH 2 Preparation of (UiO-66-NH 2 post-synthetic modification of

[0053] According to the method of embodiment 1 step (2) to UiO-66-NH 2 Perform post-synthetic modifications.

[0054] (3)PSM UiO-66-NH 2 Preparation of PSP-2 membrane of BMA

[0055] 60mg of PSM UiO-66-NH 2 Disperse in 40mg of butyl methacrylate (BMA) monomer, ultrasonic 30min, then add 6mg of photoinitiator phenyl bis (2,4,6-trimethylbenzoyl) phosphine oxide, ultrasonic 2min, the The obtained mixture was added dropwise into a polytetrafluoroethylene mold, irradiated with ultraviolet light for 30 min, and peeled off with tweezers to obtain a metal-organic framework material film with a MOFs loading of 60%, which was designated as a PSP-2 film. When irradiating, the distance between the ultraviolet light and...

Embodiment 3

[0057] (1)UiO-66-NH 2 preparation of

[0058] Prepare UiO-66-NH according to the method of Example 1 step (1) 2 . The difference is: the immersion time in ethanol is 2 days.

[0059] (2)PSM UiO-66-NH 2 Preparation of (UiO-66-NH 2 post-synthetic modification of

[0060] According to the method of embodiment 1 step (2) to UiO-66-NH 2 Perform post-synthetic modifications.

[0061] (3)PSM UiO-66-NH 2 Preparation of PSP-3 membrane with MMA

[0062] 20mg of PSM UiO-66-NH 2 Disperse in 180 mg of methyl methacrylate (MMA) monomer, ultrasonic 15 min, then add 12 mg of photoinitiator phenyl bis (2,4,6-trimethylbenzoyl) phosphine oxide, ultrasonic 2 min, the The obtained mixture was added dropwise into a polytetrafluoroethylene mold, irradiated with ultraviolet light for 15 minutes, and peeled off with tweezers to obtain a metal-organic framework material film with a MOFs loading of 10%, which was designated as a PSP-3 film. When irradiating, the distance between the ultraviolet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com